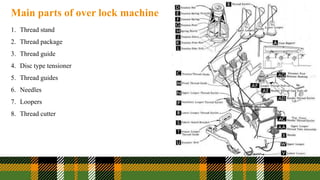

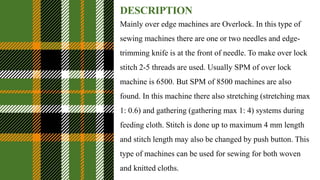

1) The document discusses an overlock sewing machine, which is a specialized machine used for edge finishing and seaming. It has one or two needles and loopers and uses 2-5 threads to make an overlock stitch.

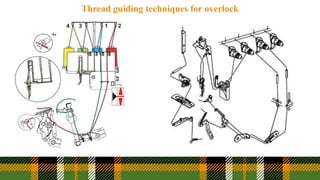

2) The objectives are to learn about the machine parts, thread path, maintenance needs, and replacement timing of overlock machines.

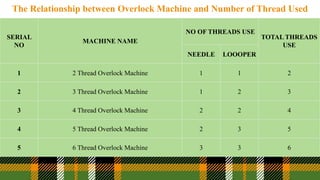

3) Overlock machines come in 3, 4, and 5 thread versions and have specifications like brand, model, stitches per minute, and needle and looper counts that vary by the number of threads used.