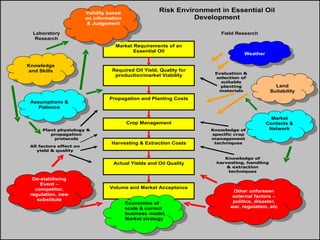

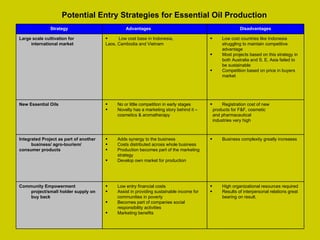

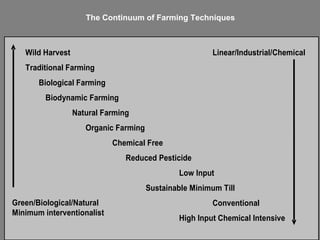

The document discusses frameworks for selecting and developing new essential oil crops. It outlines several key factors to consider, including the regulatory environment, screening potential crops and cultivation sites, developing business strategies, and evaluating the characteristics and market potential of new essential oils. Developing new essential oil crops requires focusing on product applications, accessing worldwide data, conducting research on technical and economic feasibility, and coordinating production and marketing infrastructure.