Embed presentation

Downloaded 30 times

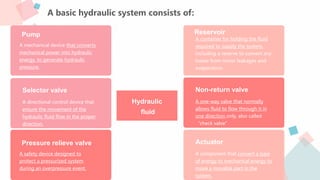

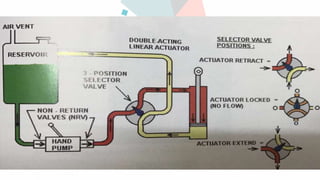

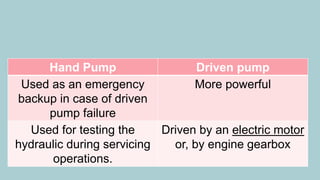

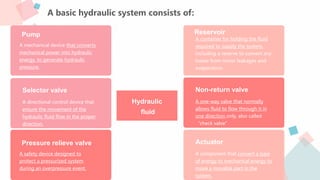

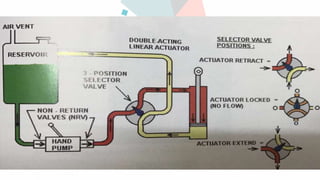

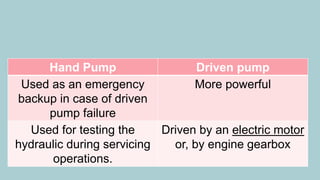

This document provides an overview of the basic components of a hydraulic system. It discusses the minimum components needed for any hydraulic system, including a pump to generate hydraulic pressure, a reservoir to hold the fluid, selector valves to control fluid direction, non-return valves, pressure relief valves, and actuators to convert hydraulic energy into mechanical motion. It also distinguishes between hand pumps, which are manually operated backup pumps, and driven pumps, which are more powerful pumps driven by electric motors or engine gearboxes.