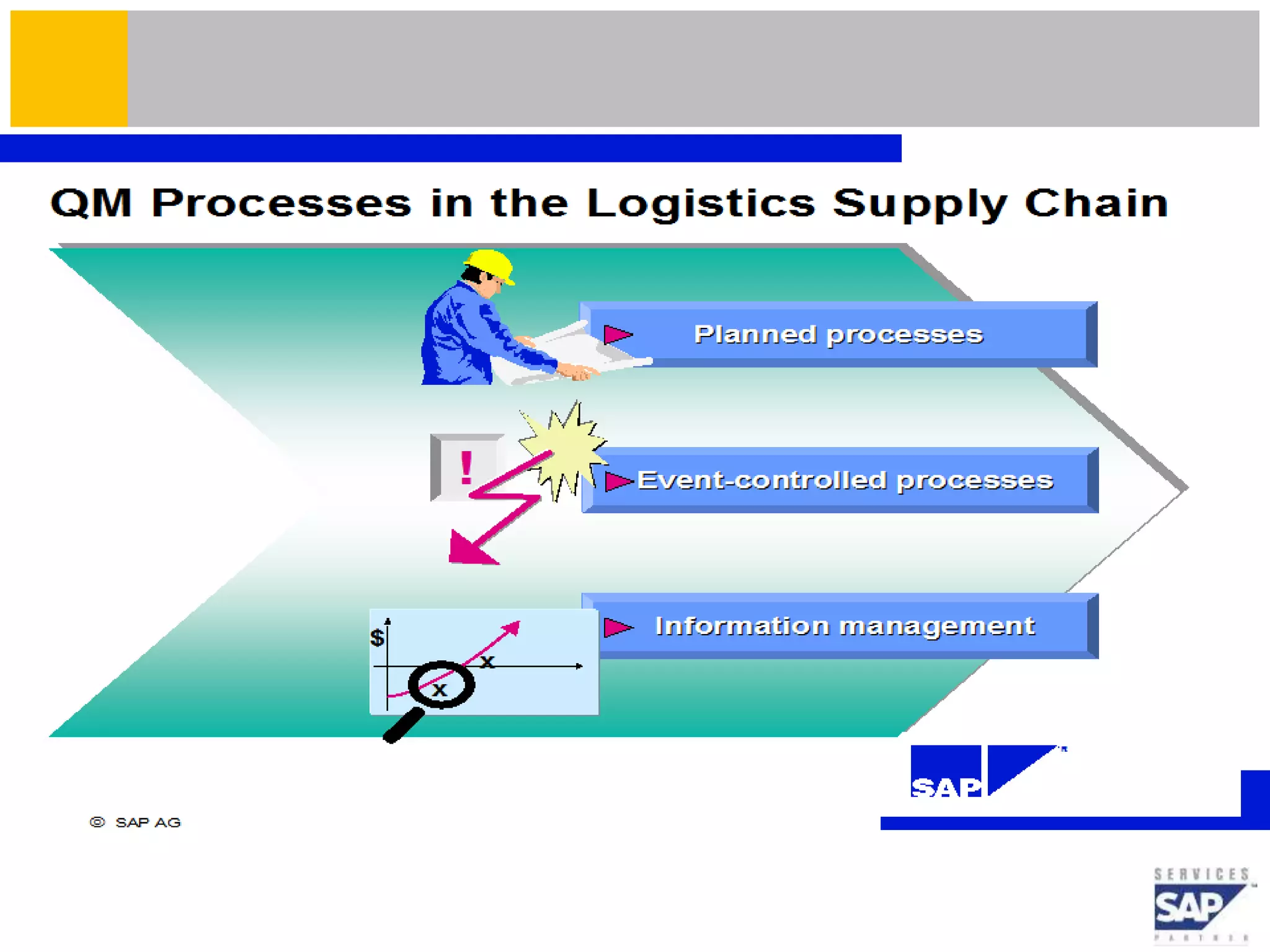

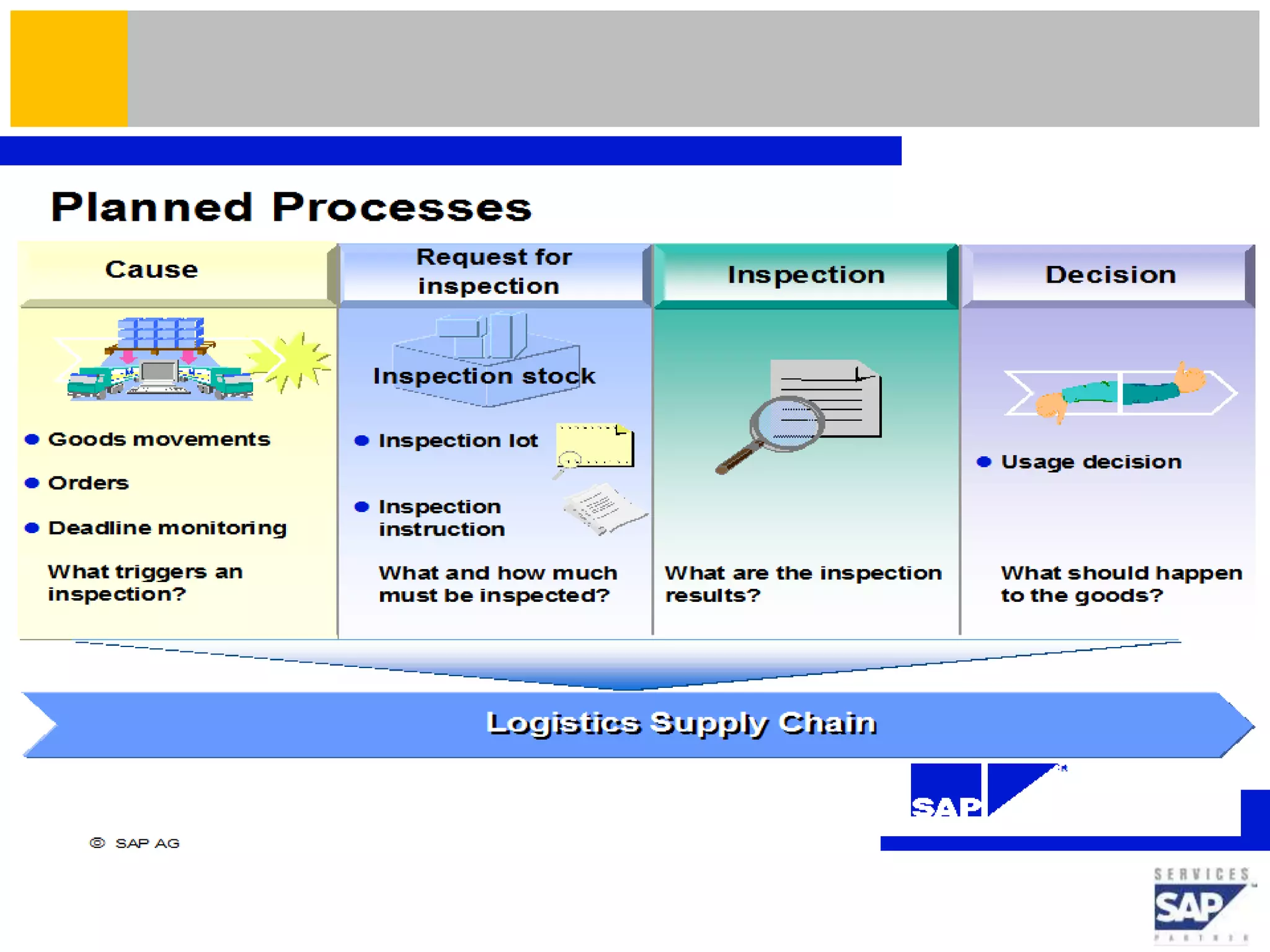

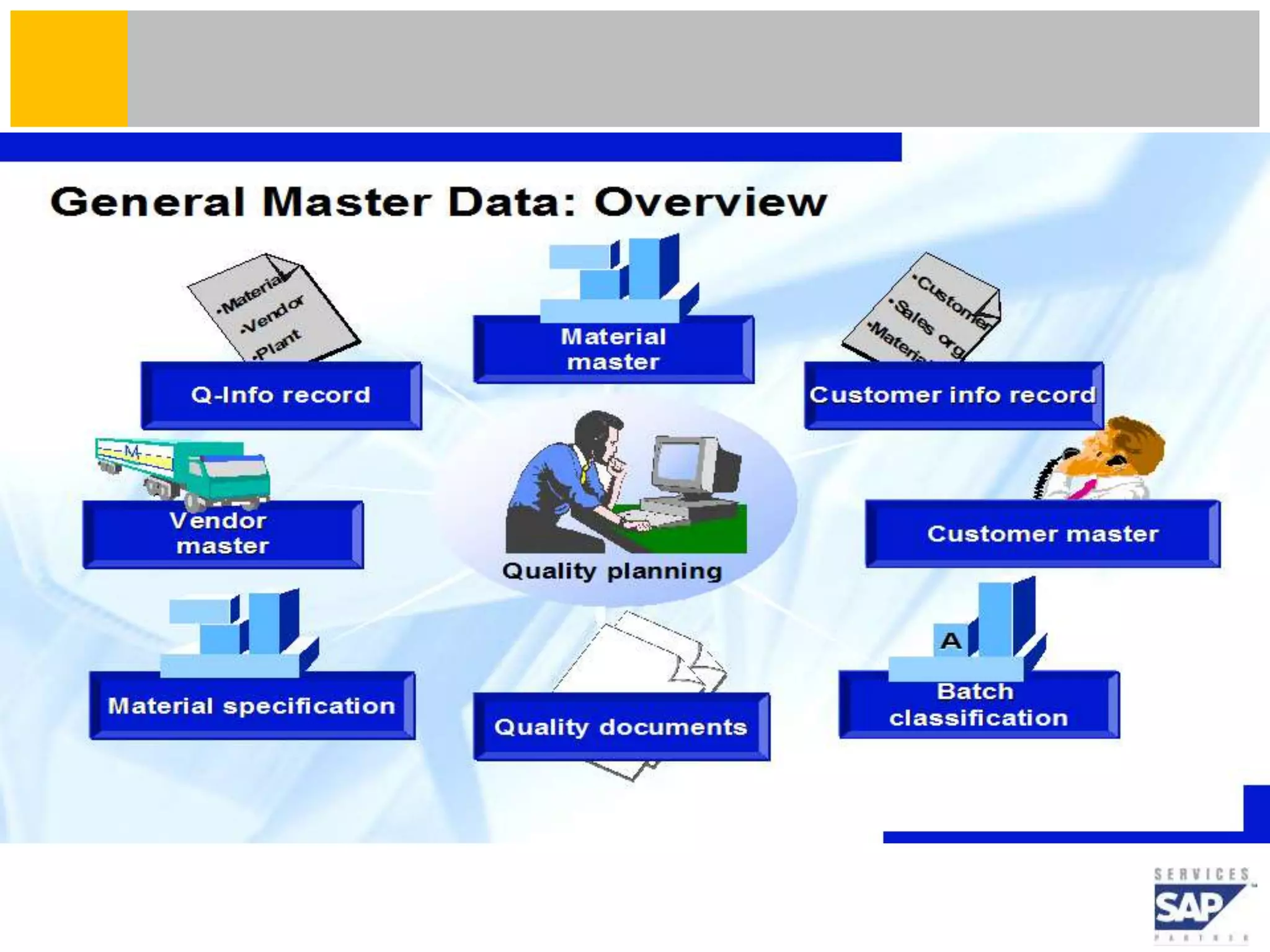

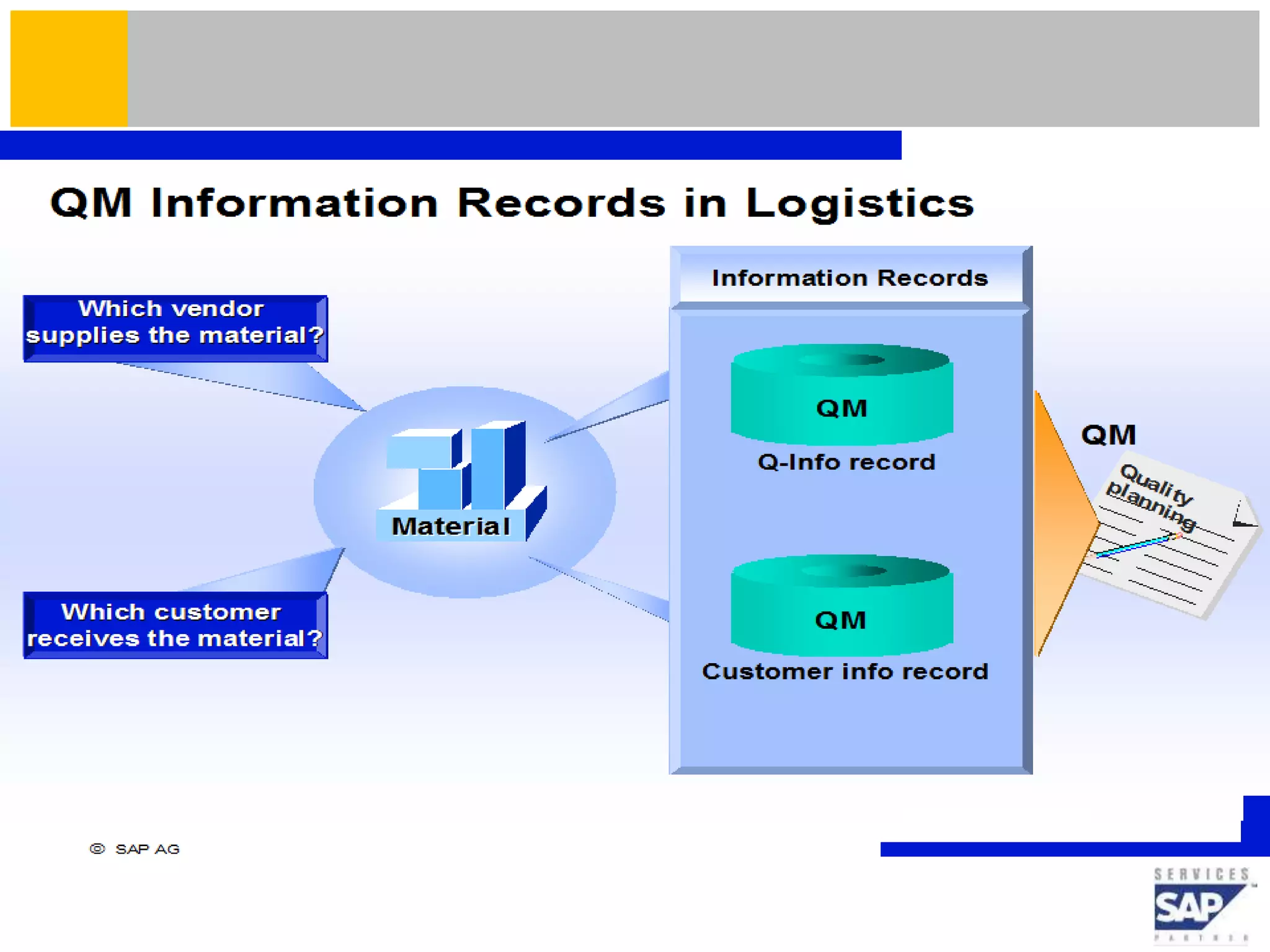

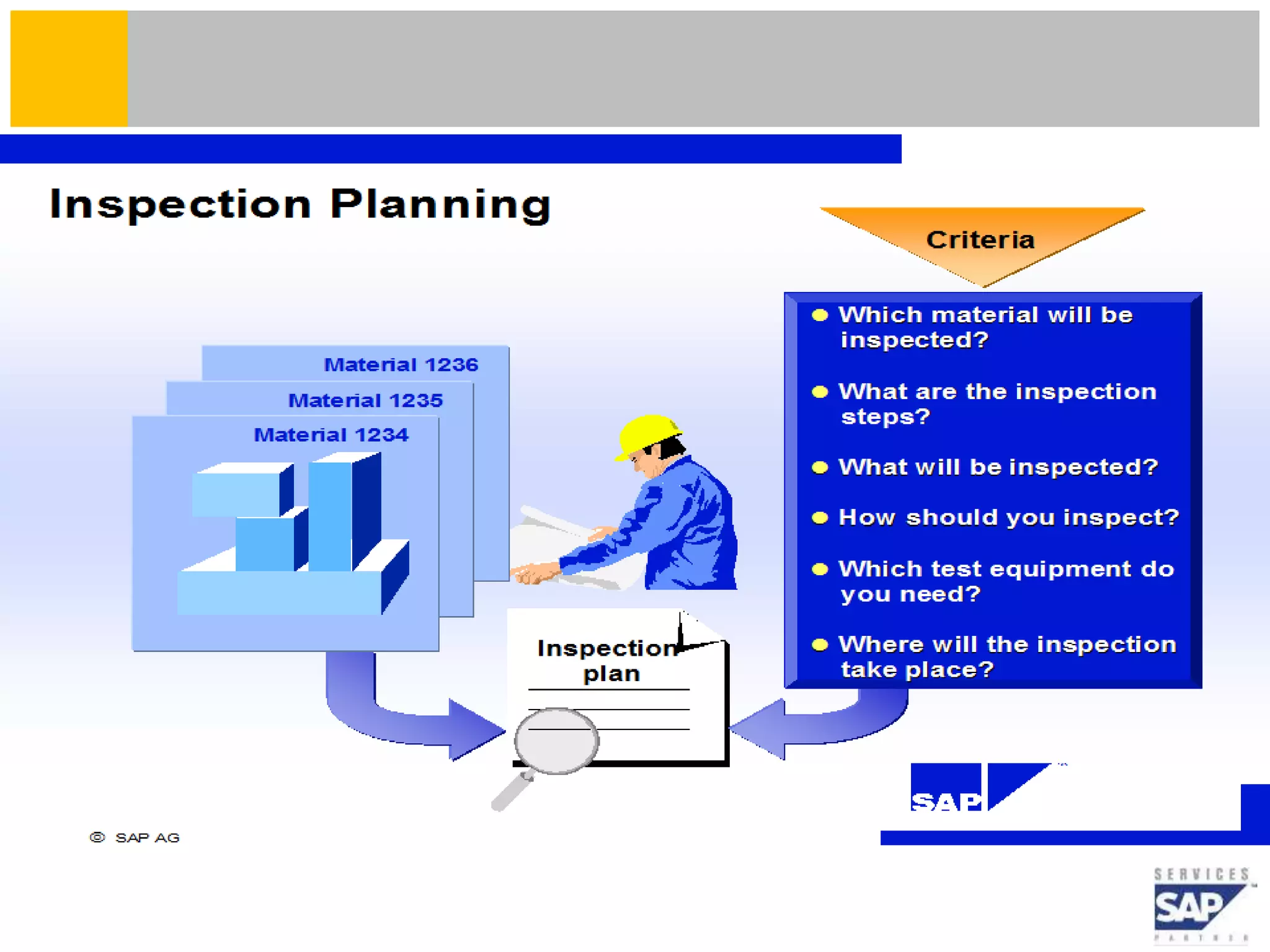

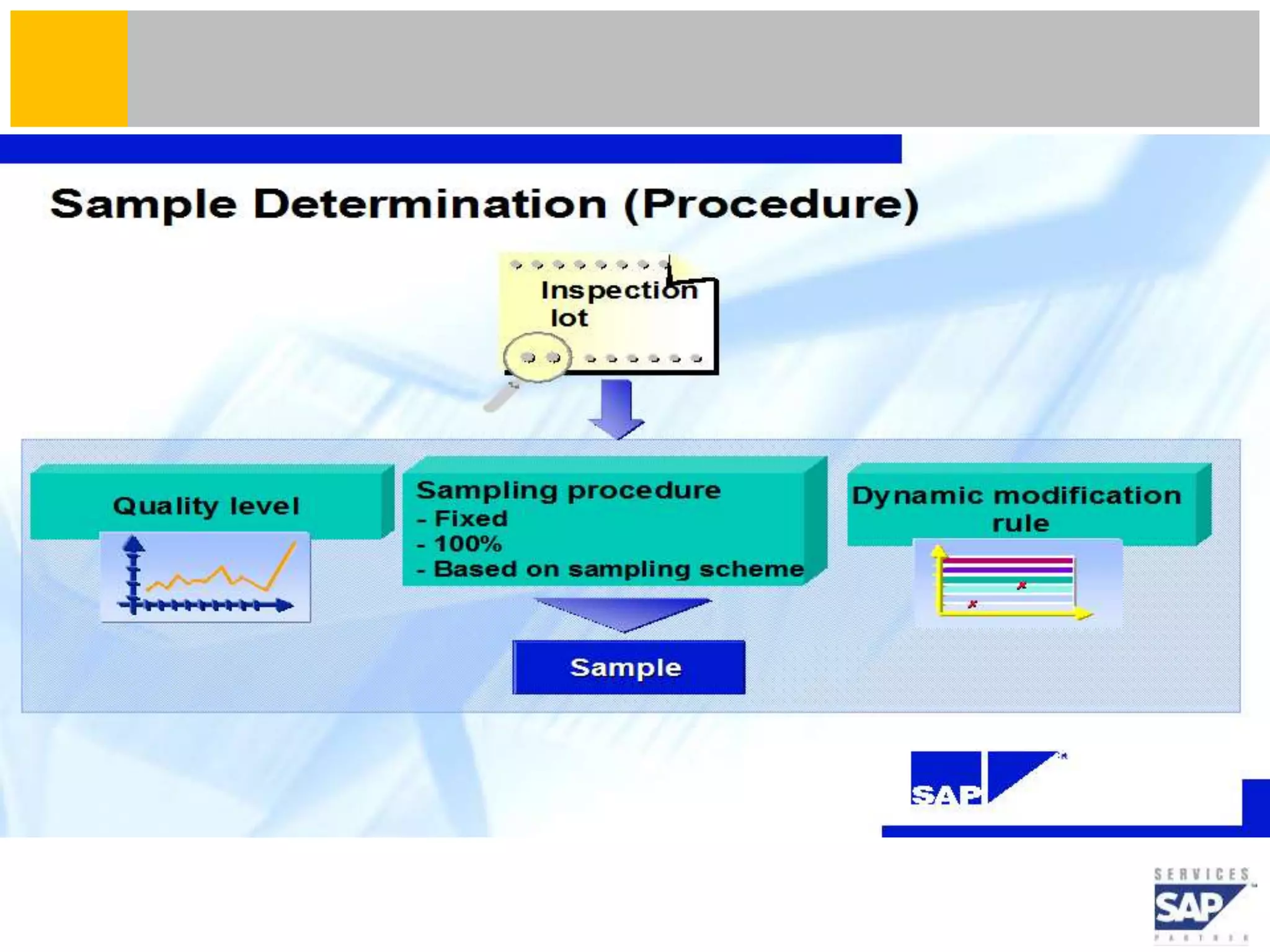

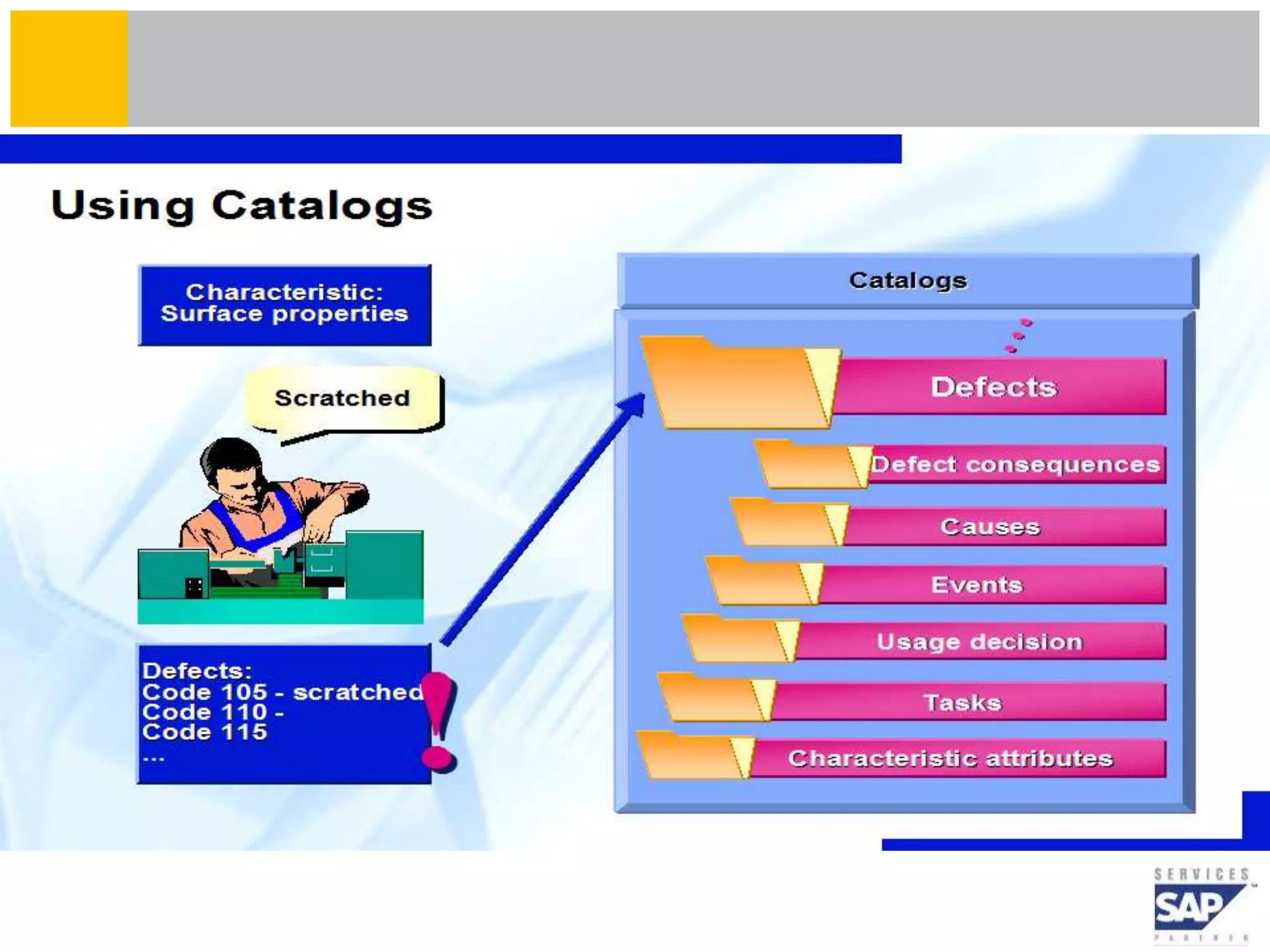

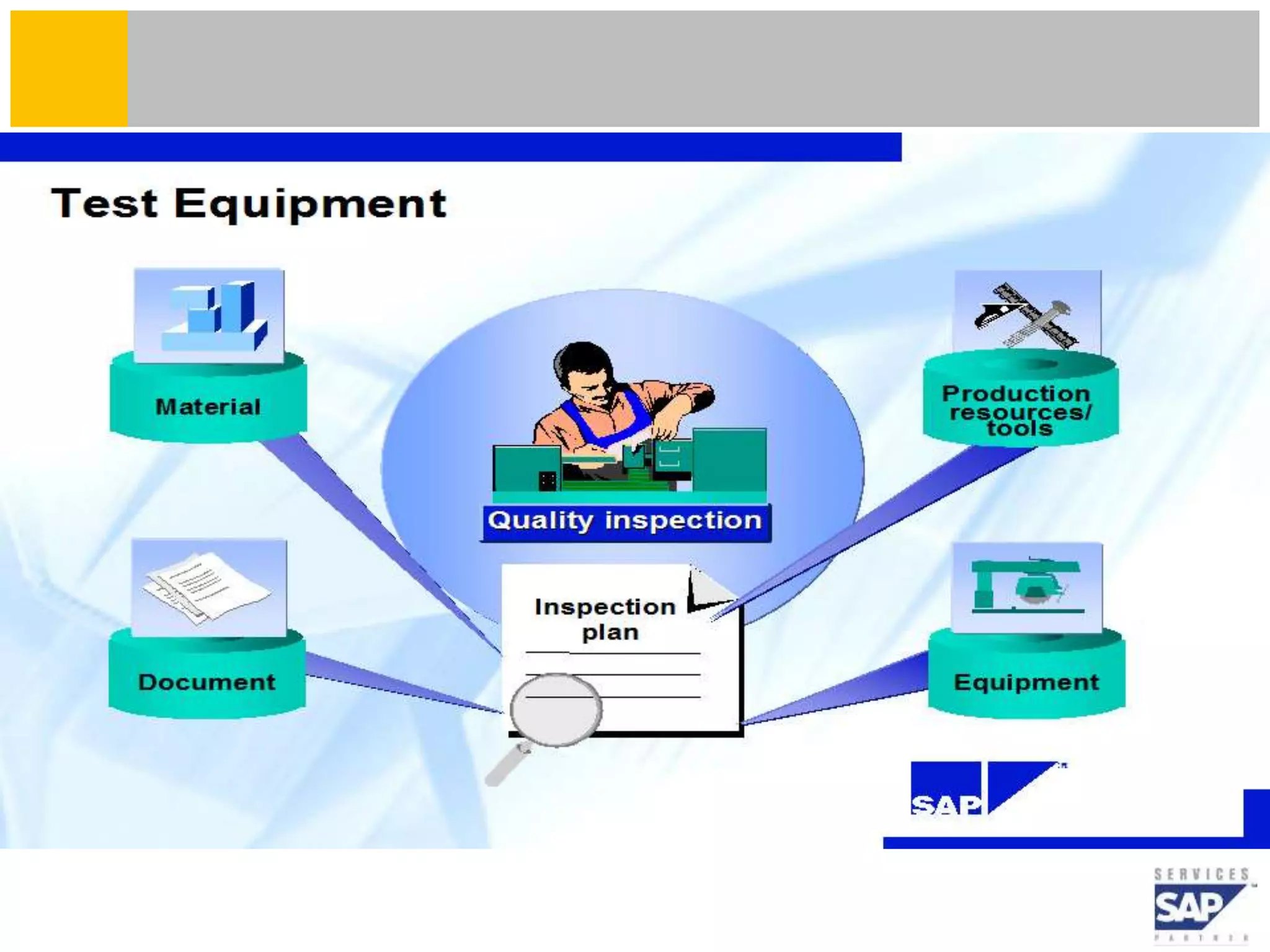

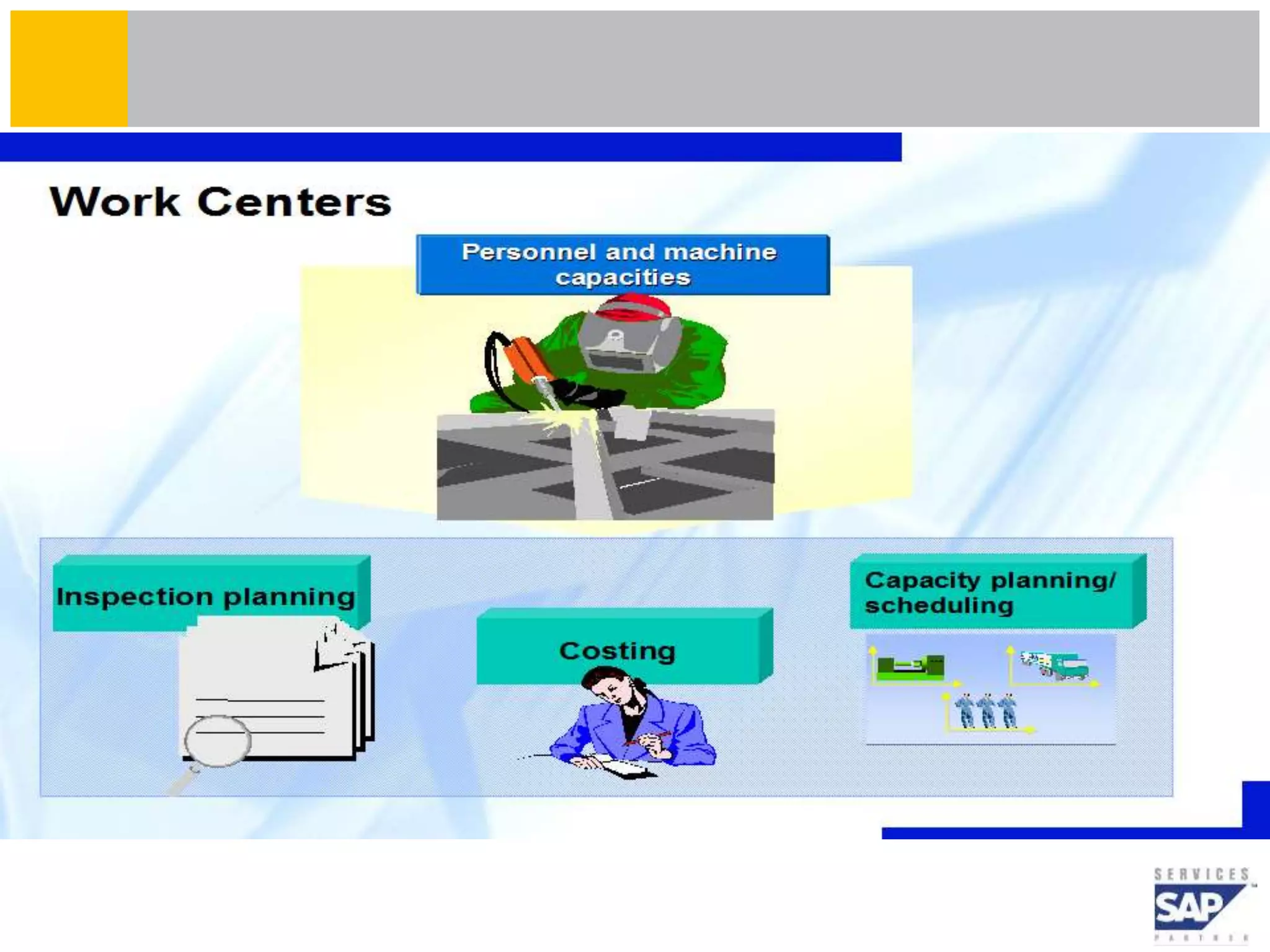

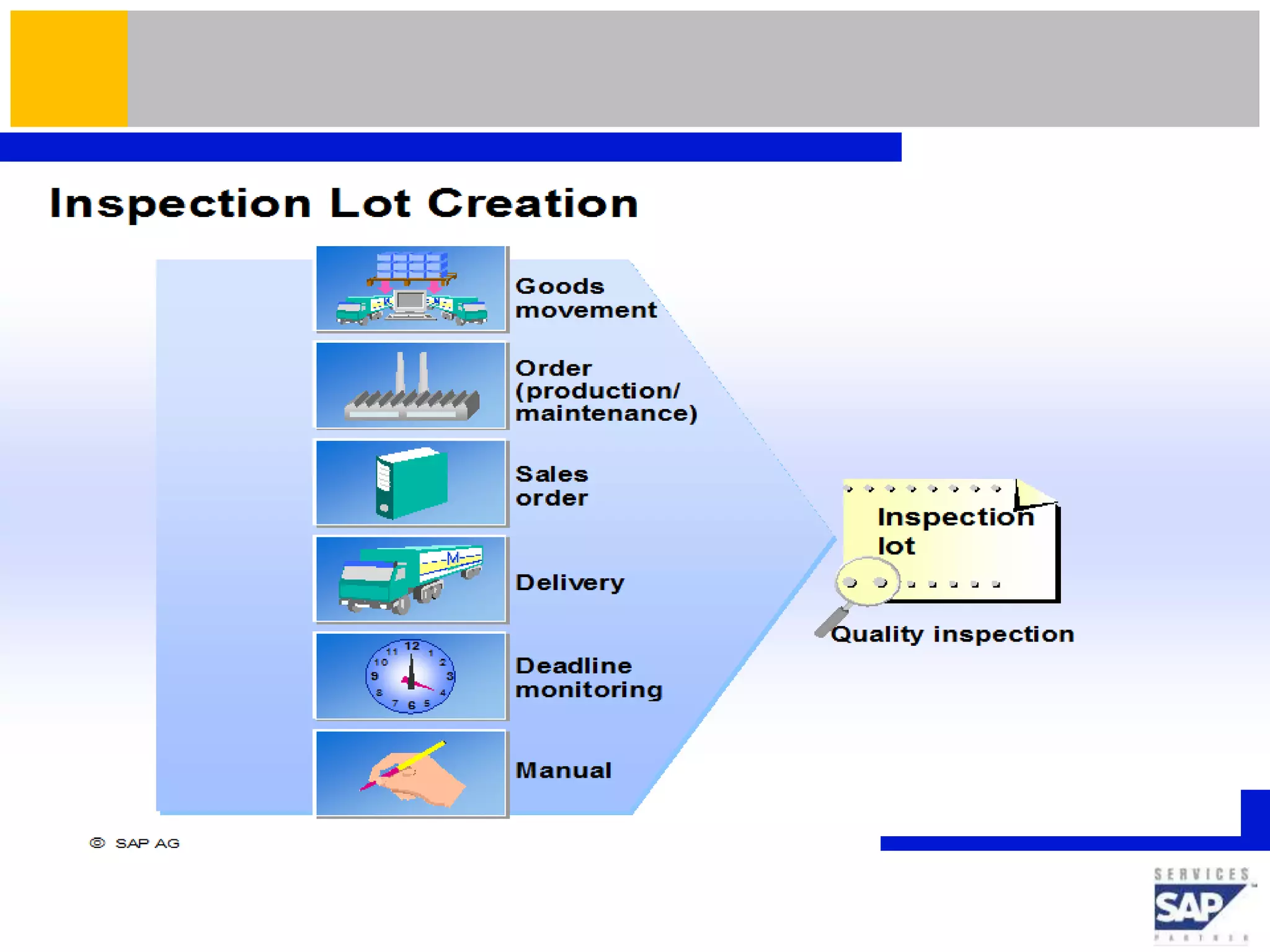

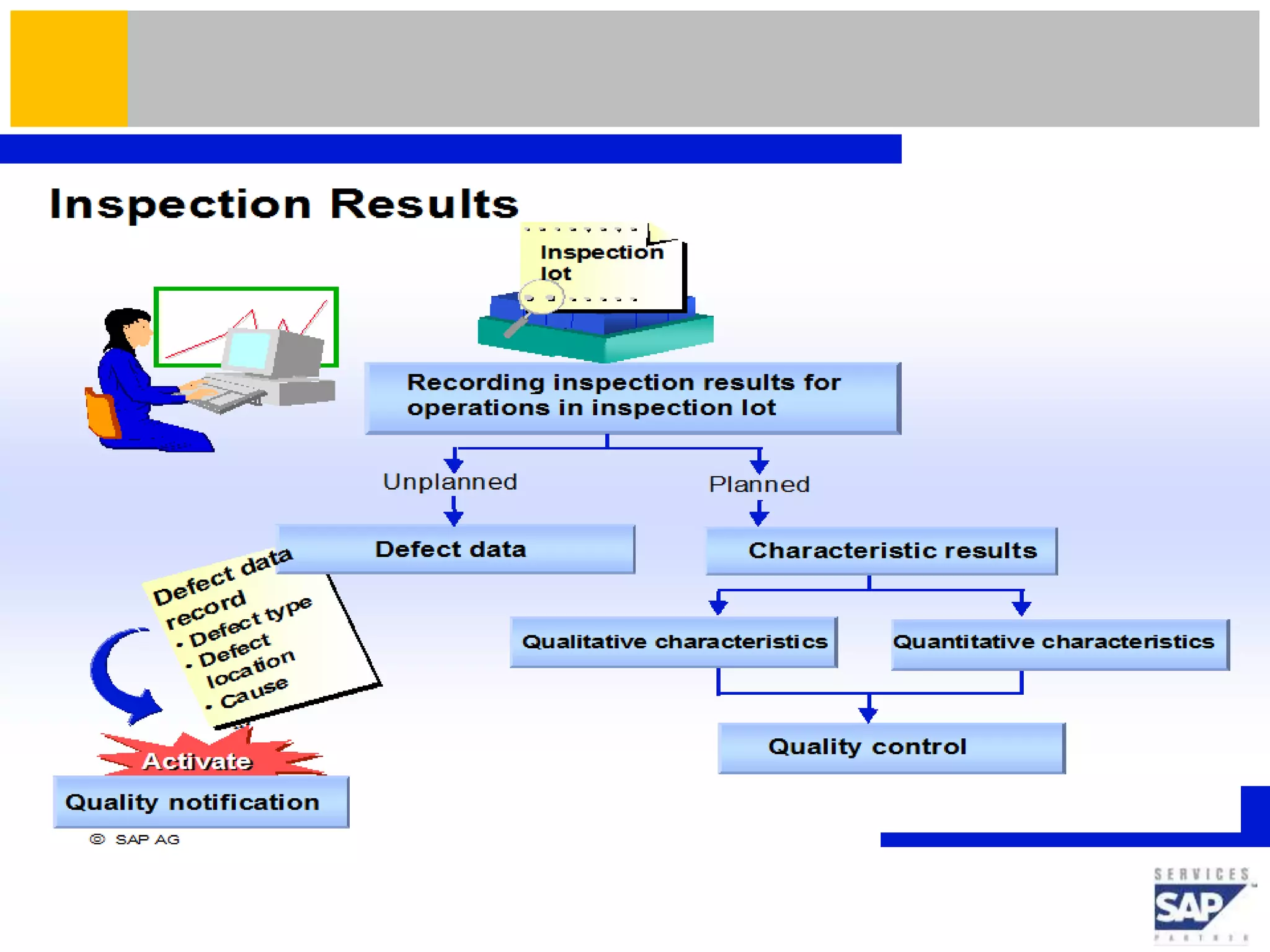

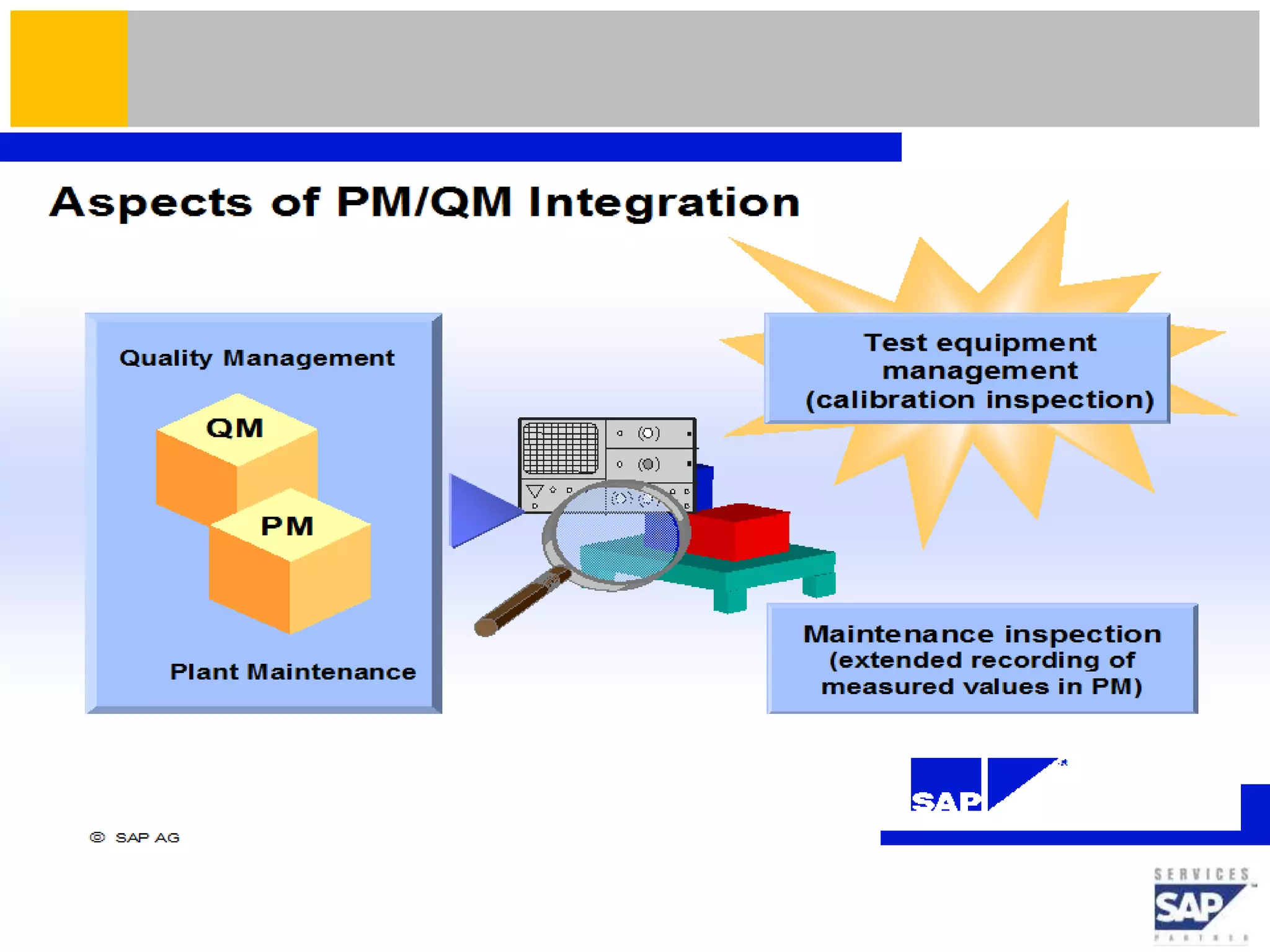

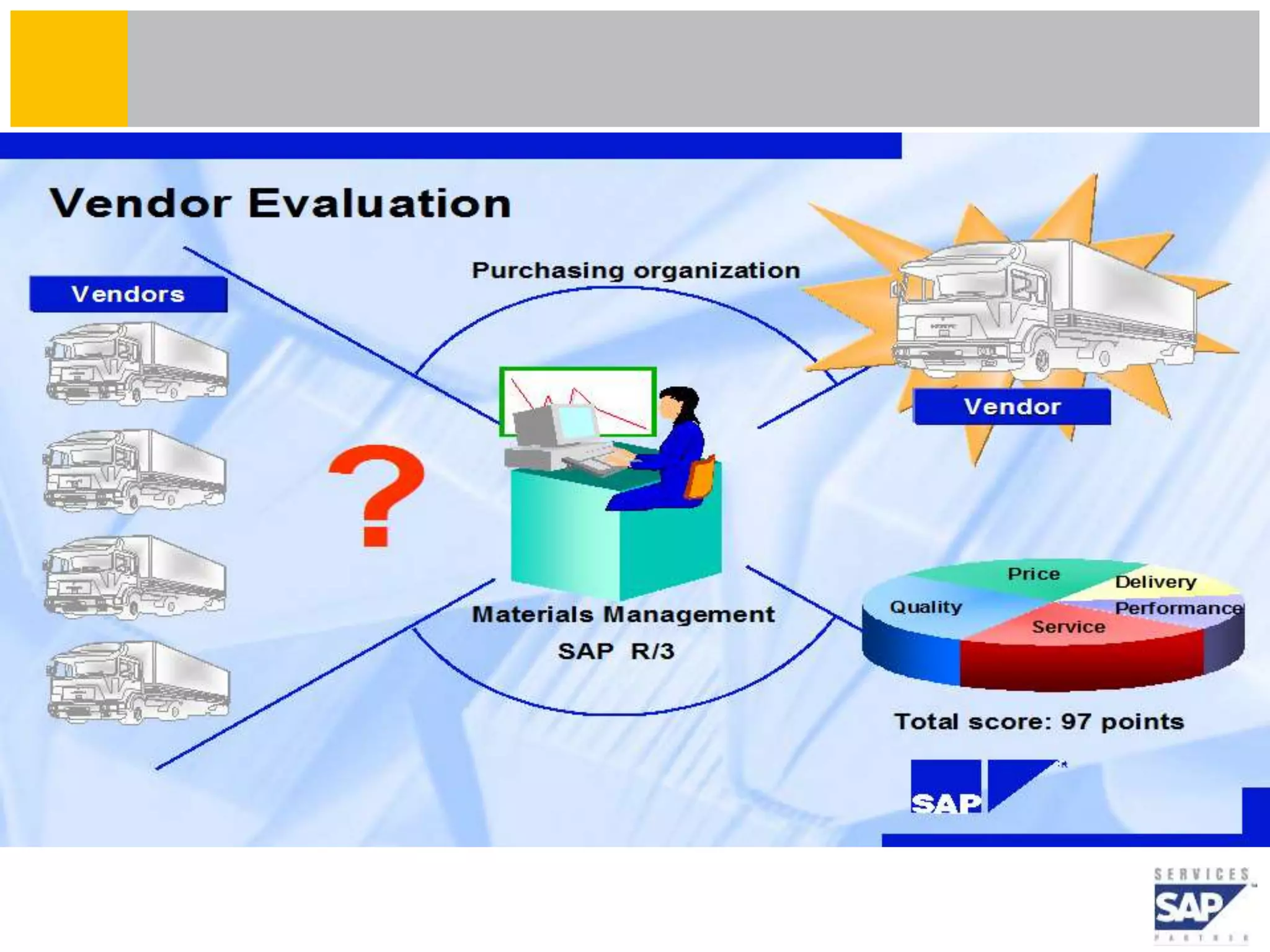

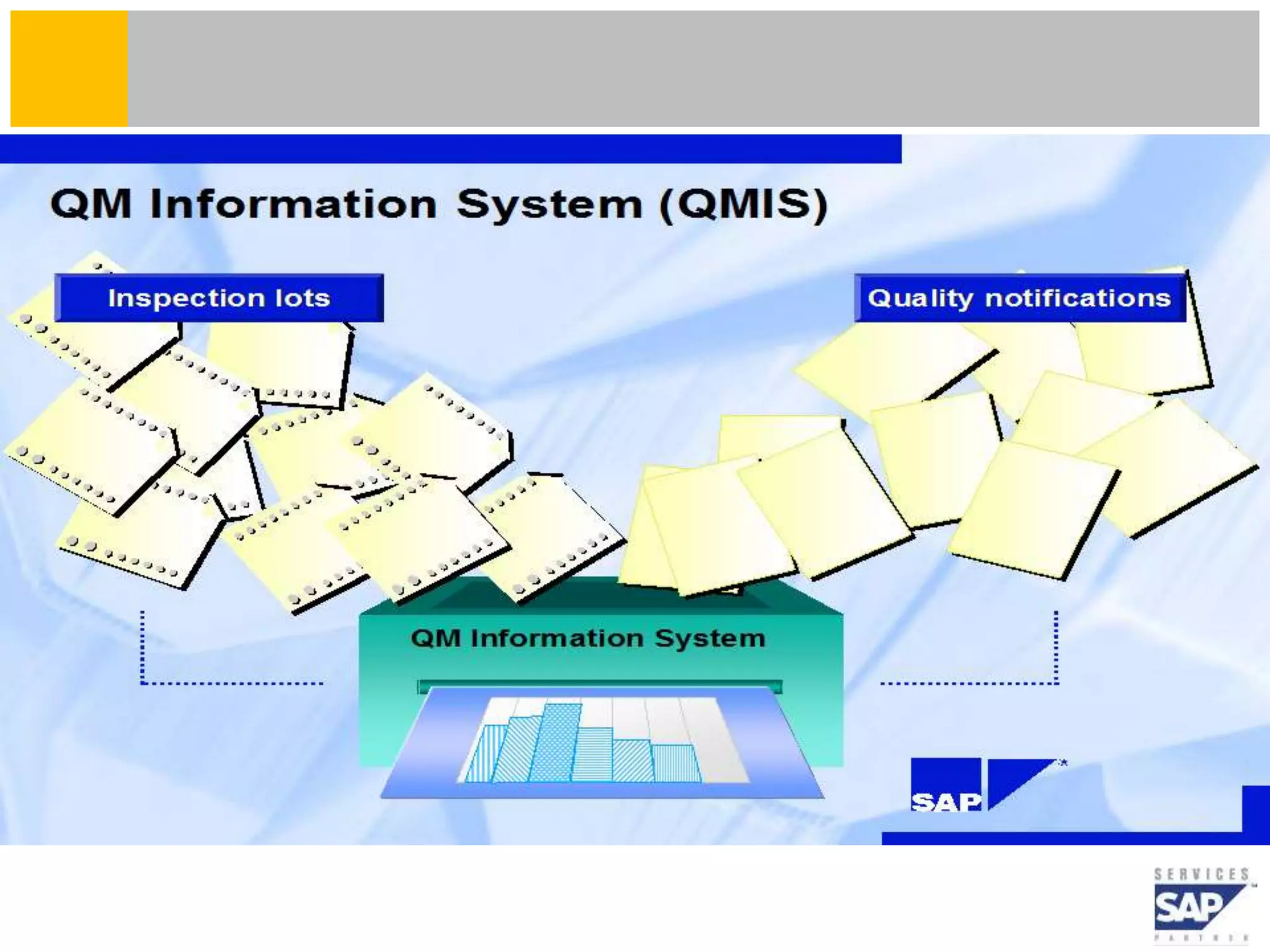

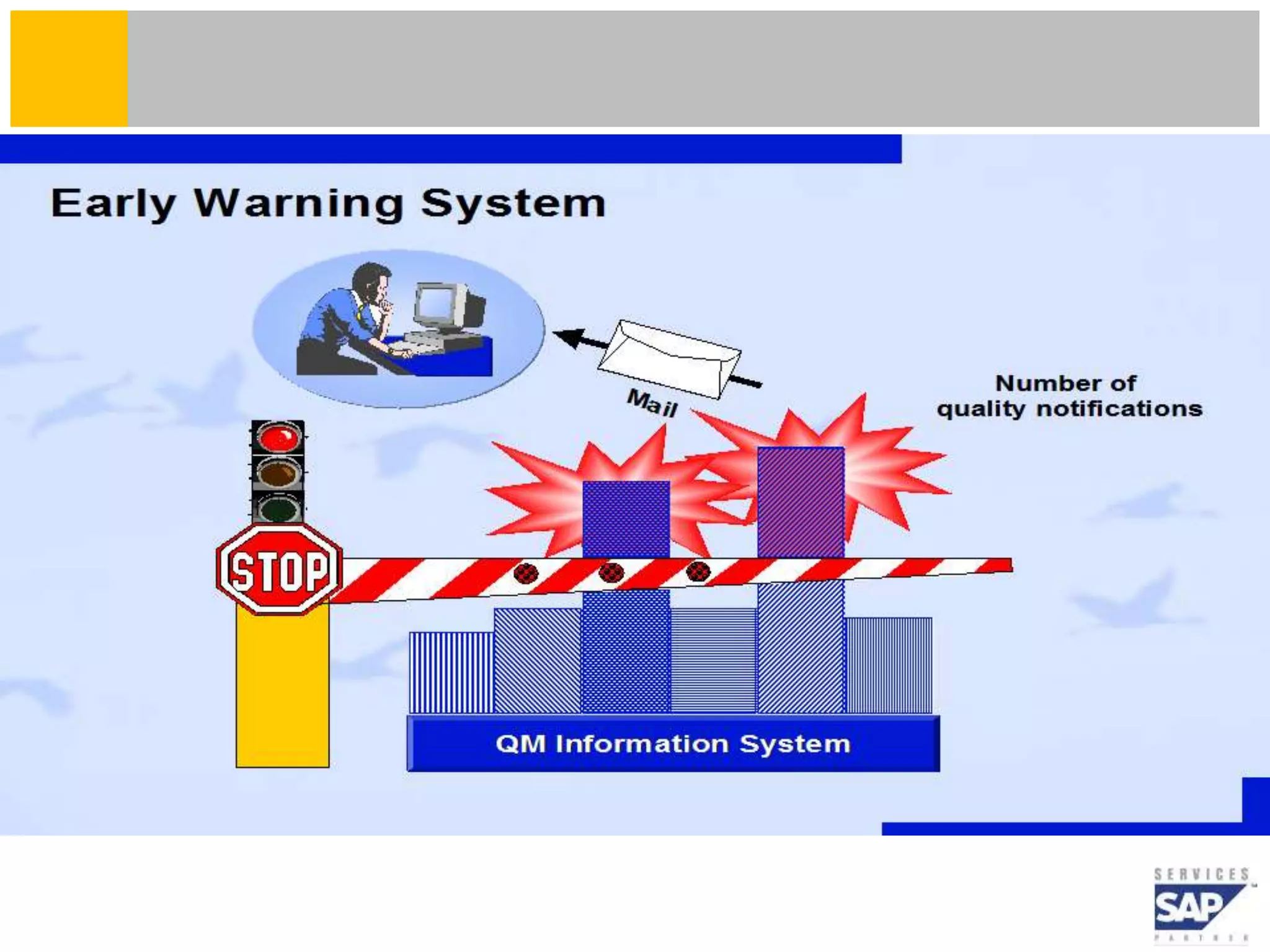

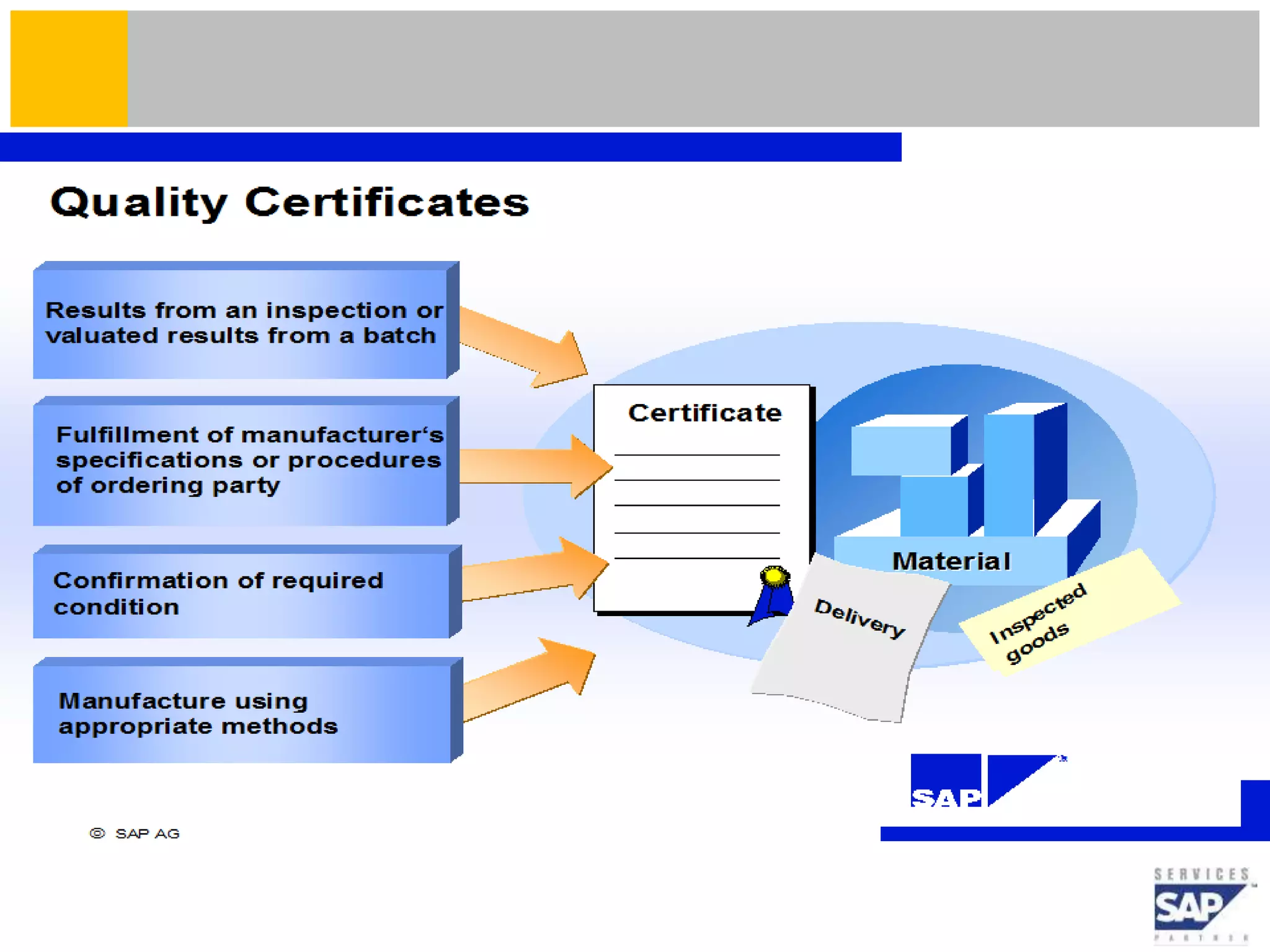

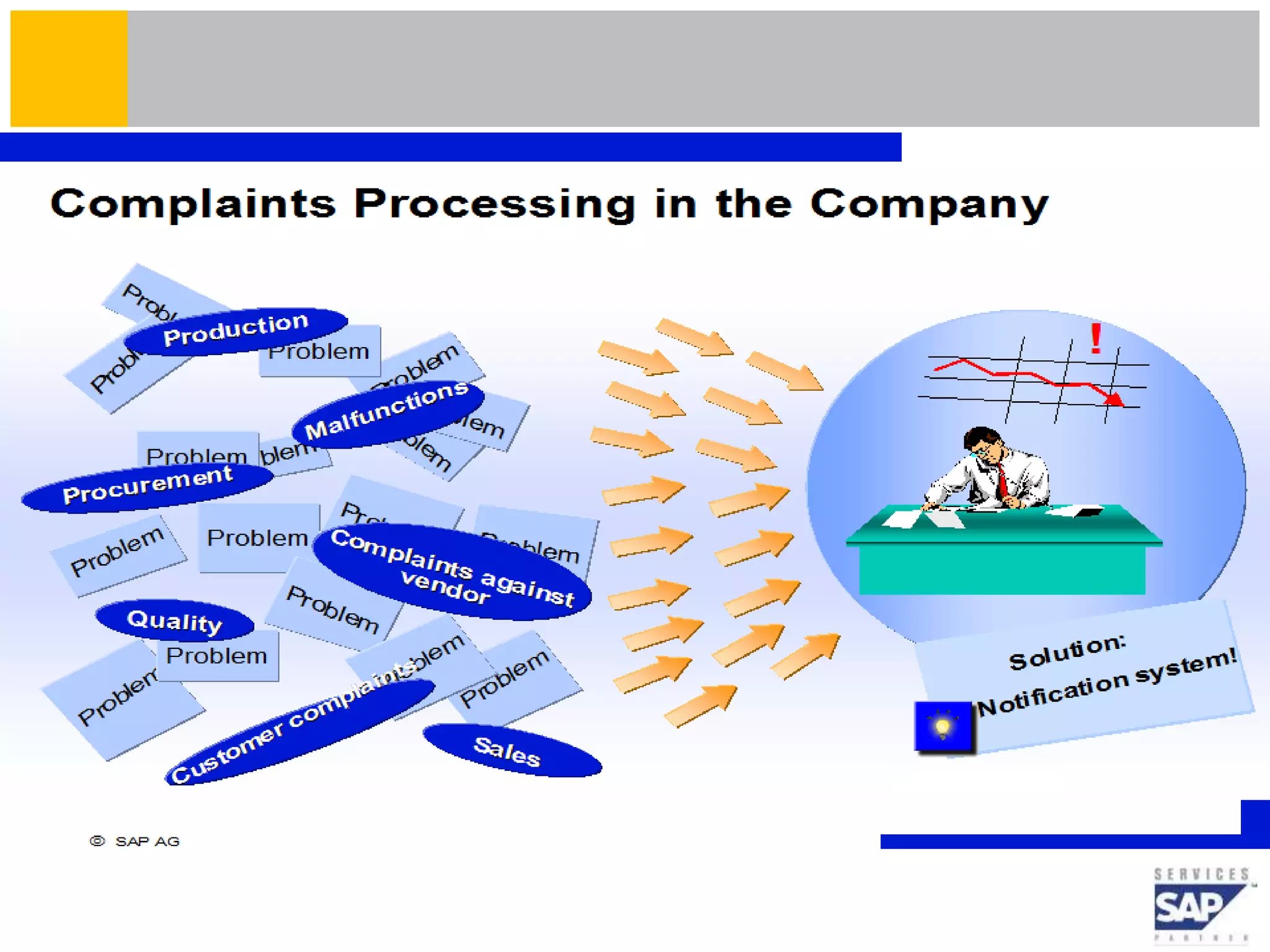

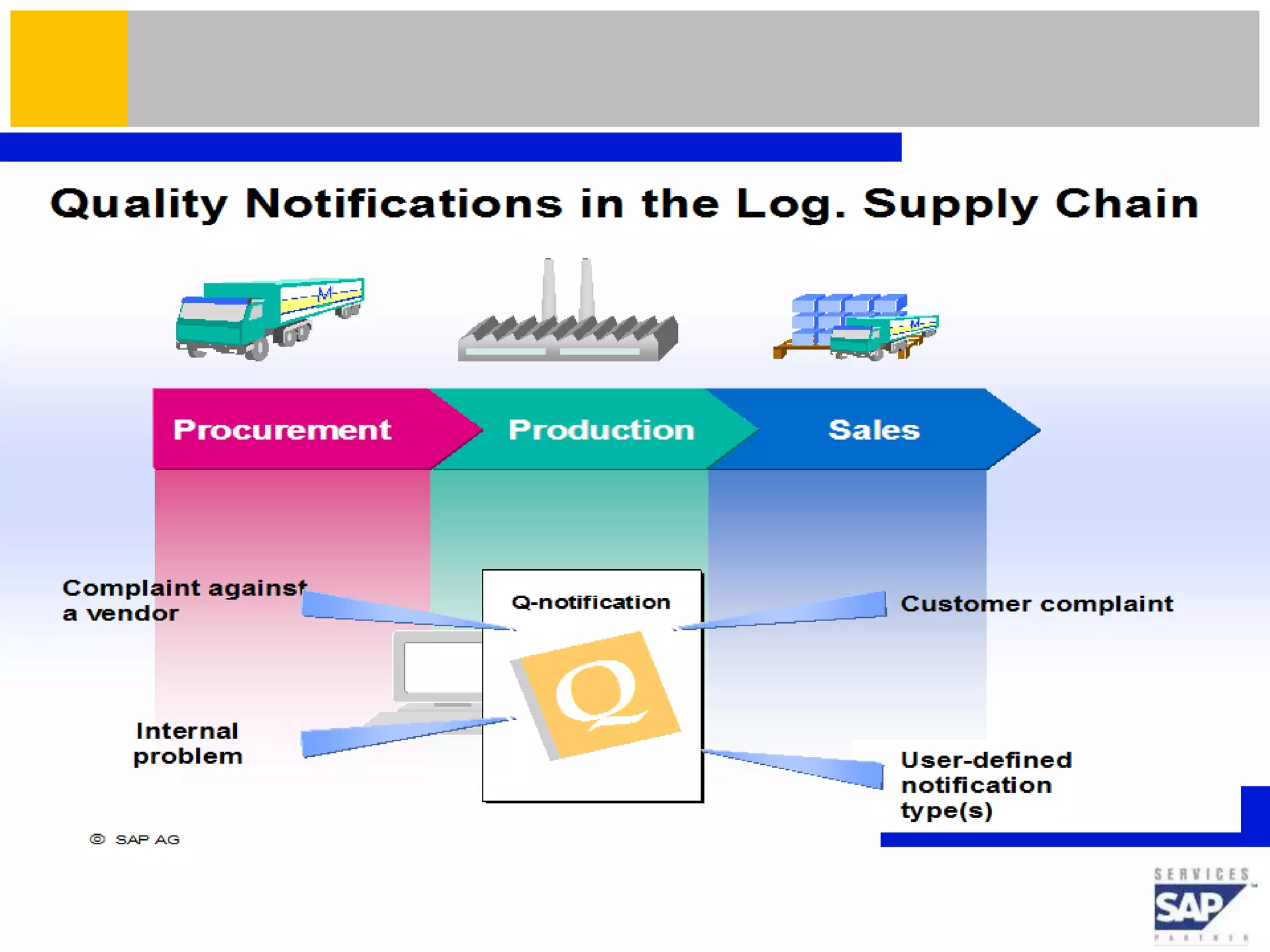

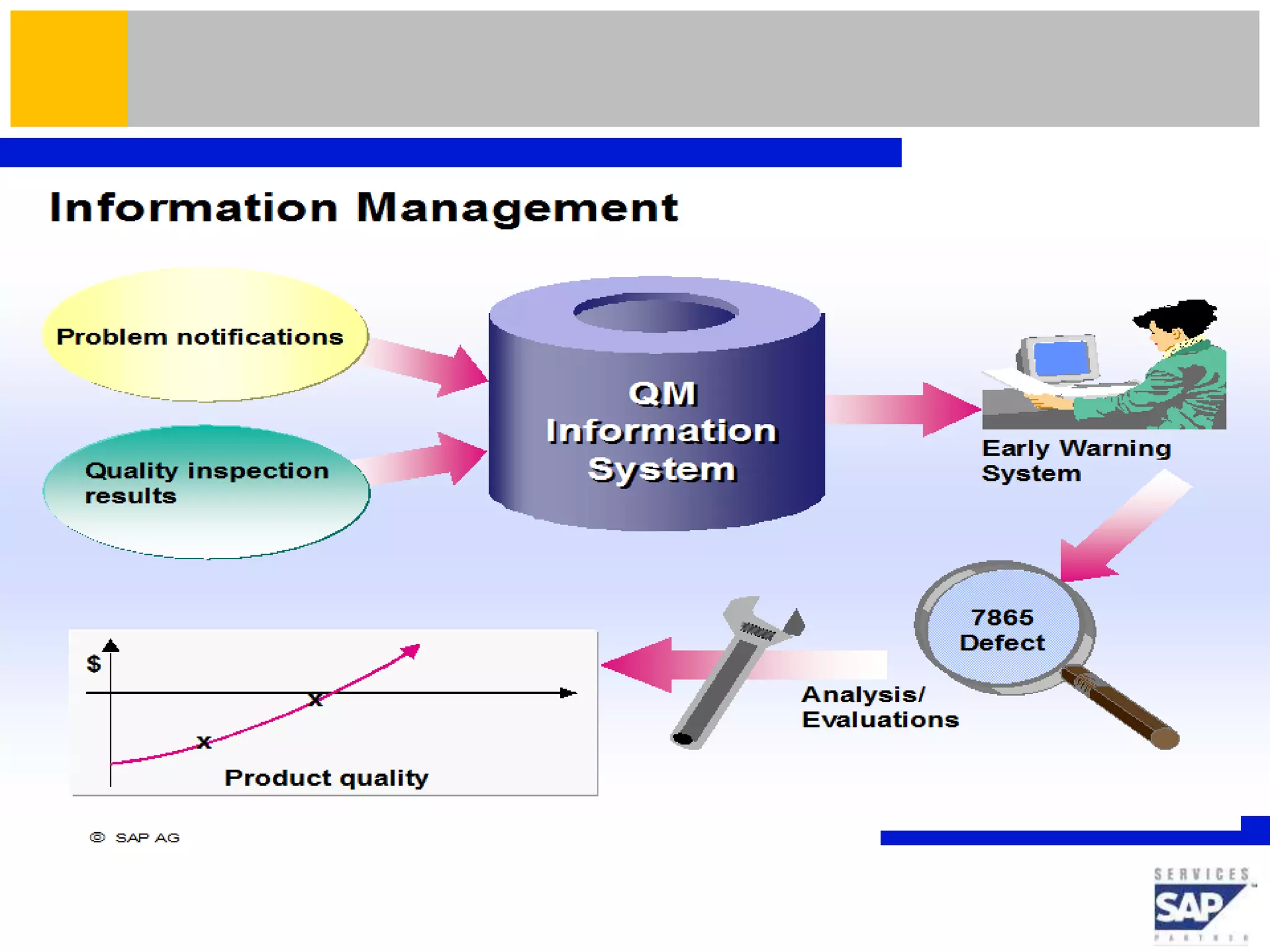

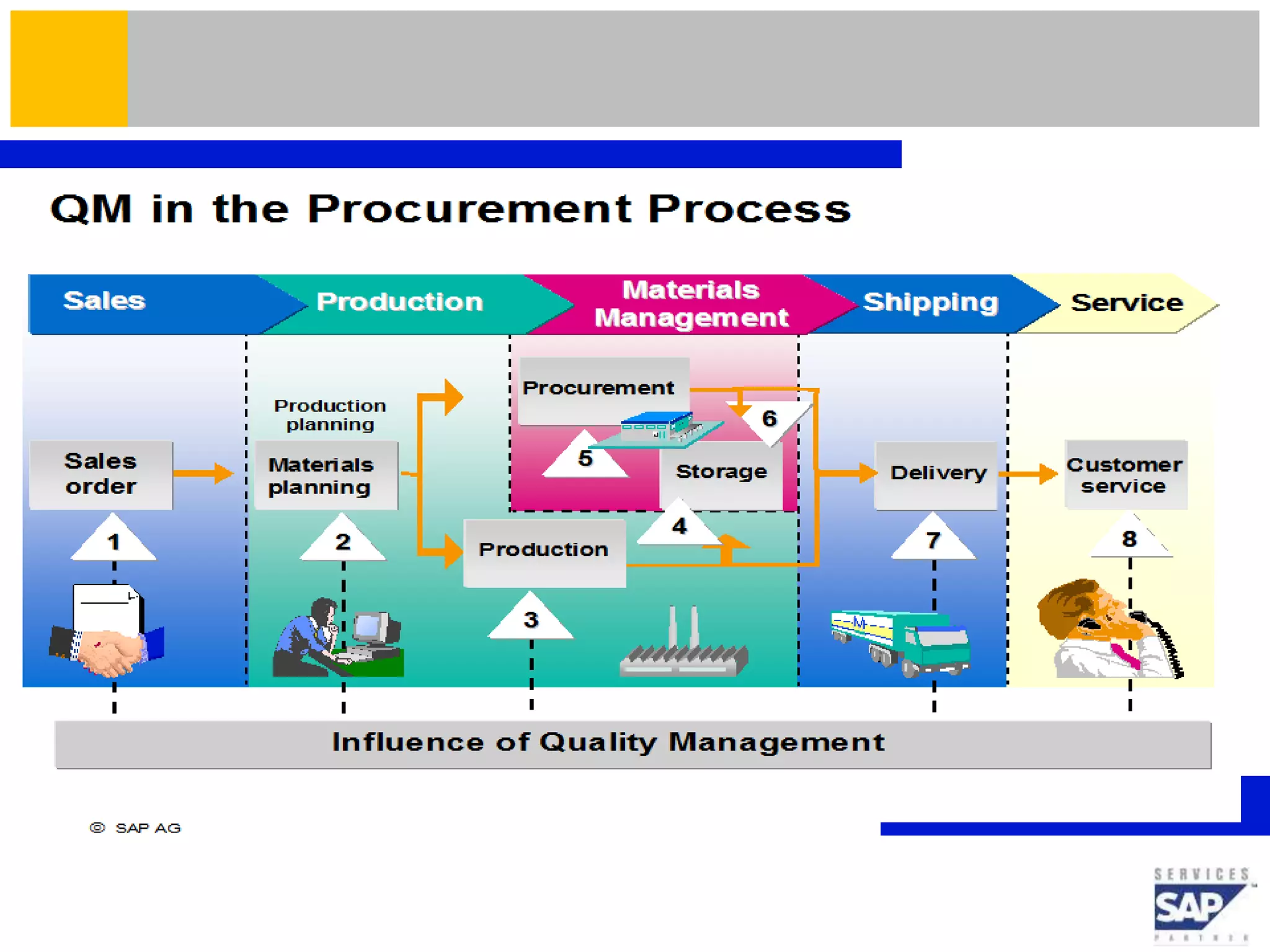

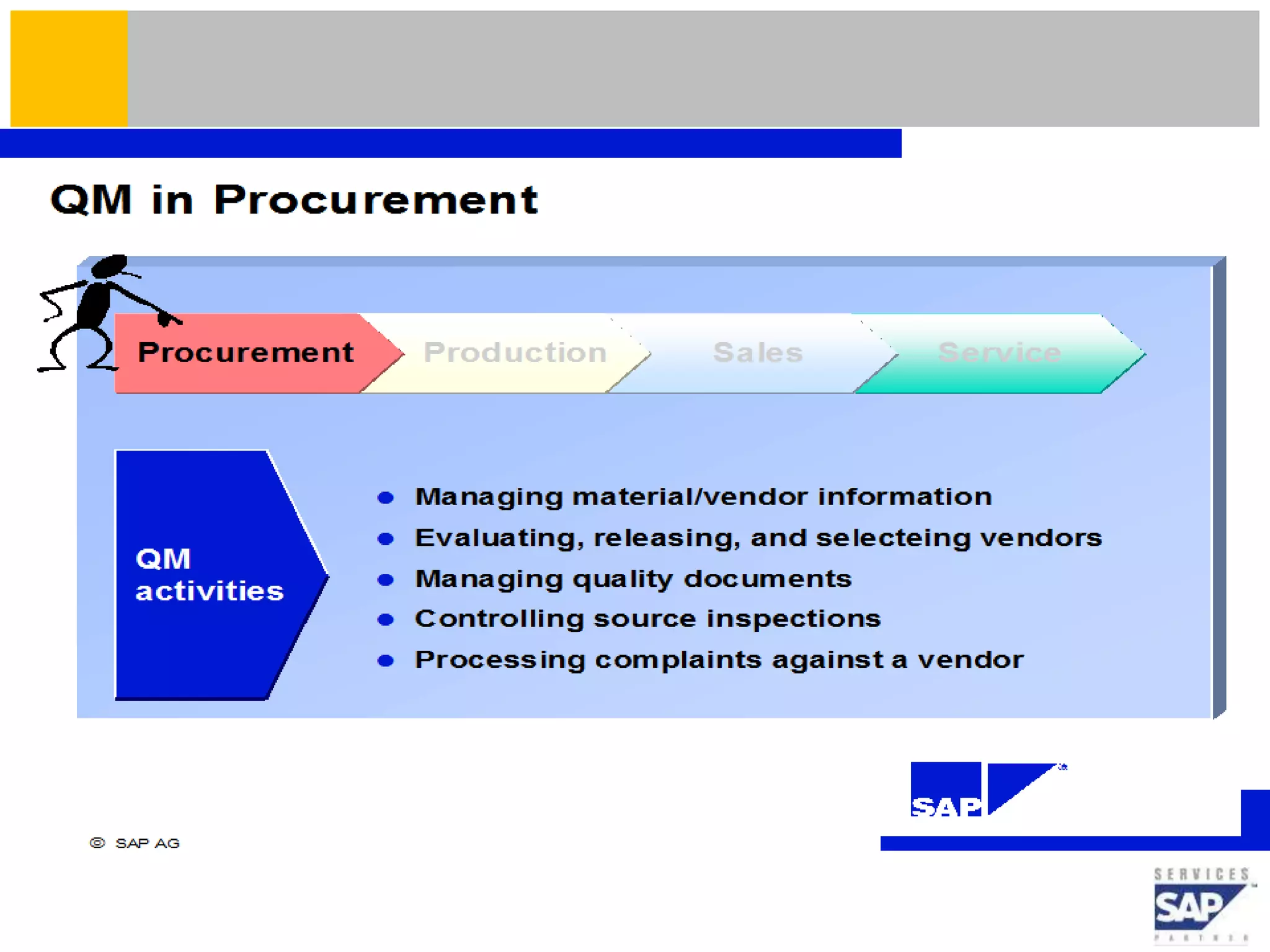

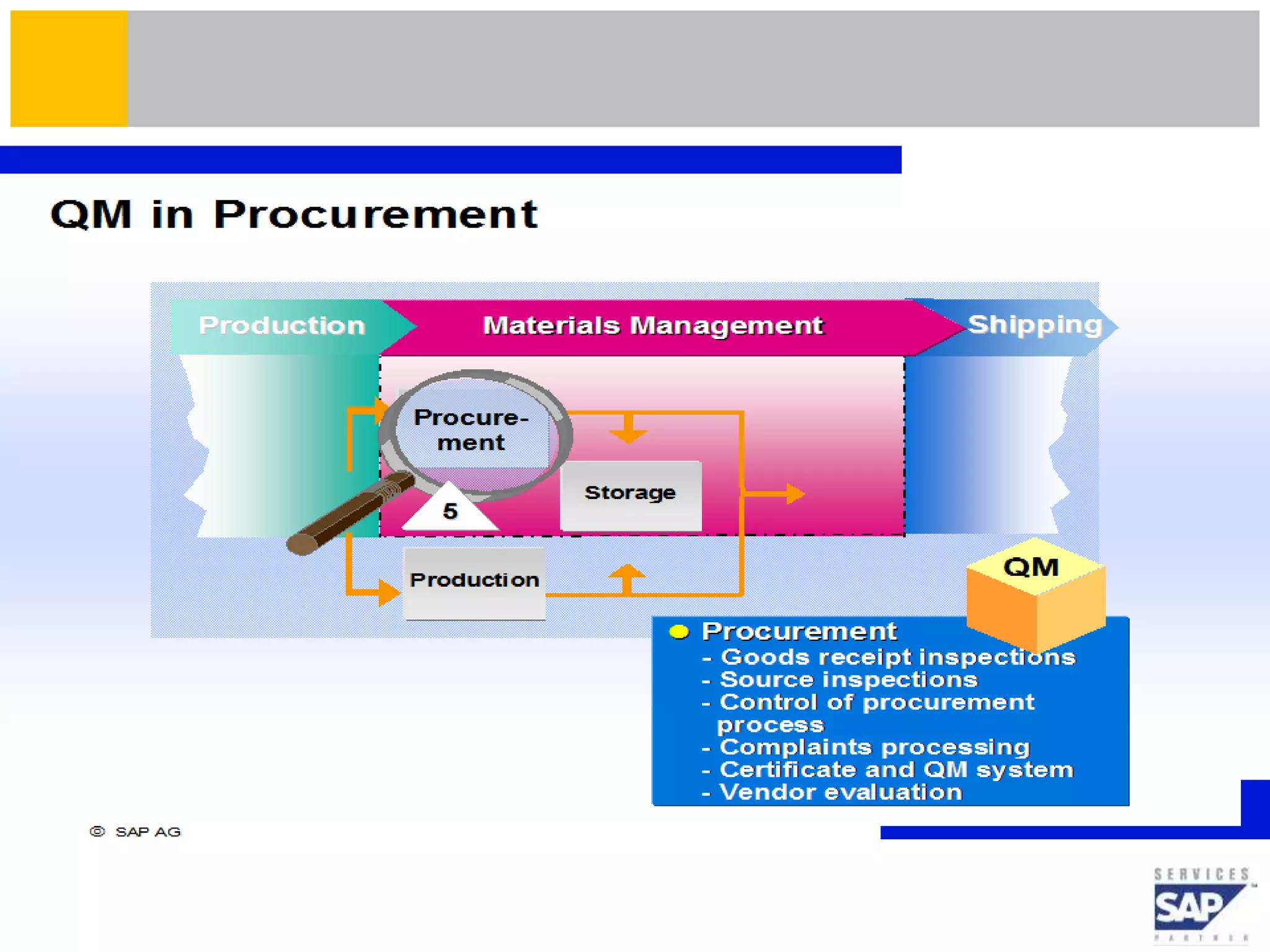

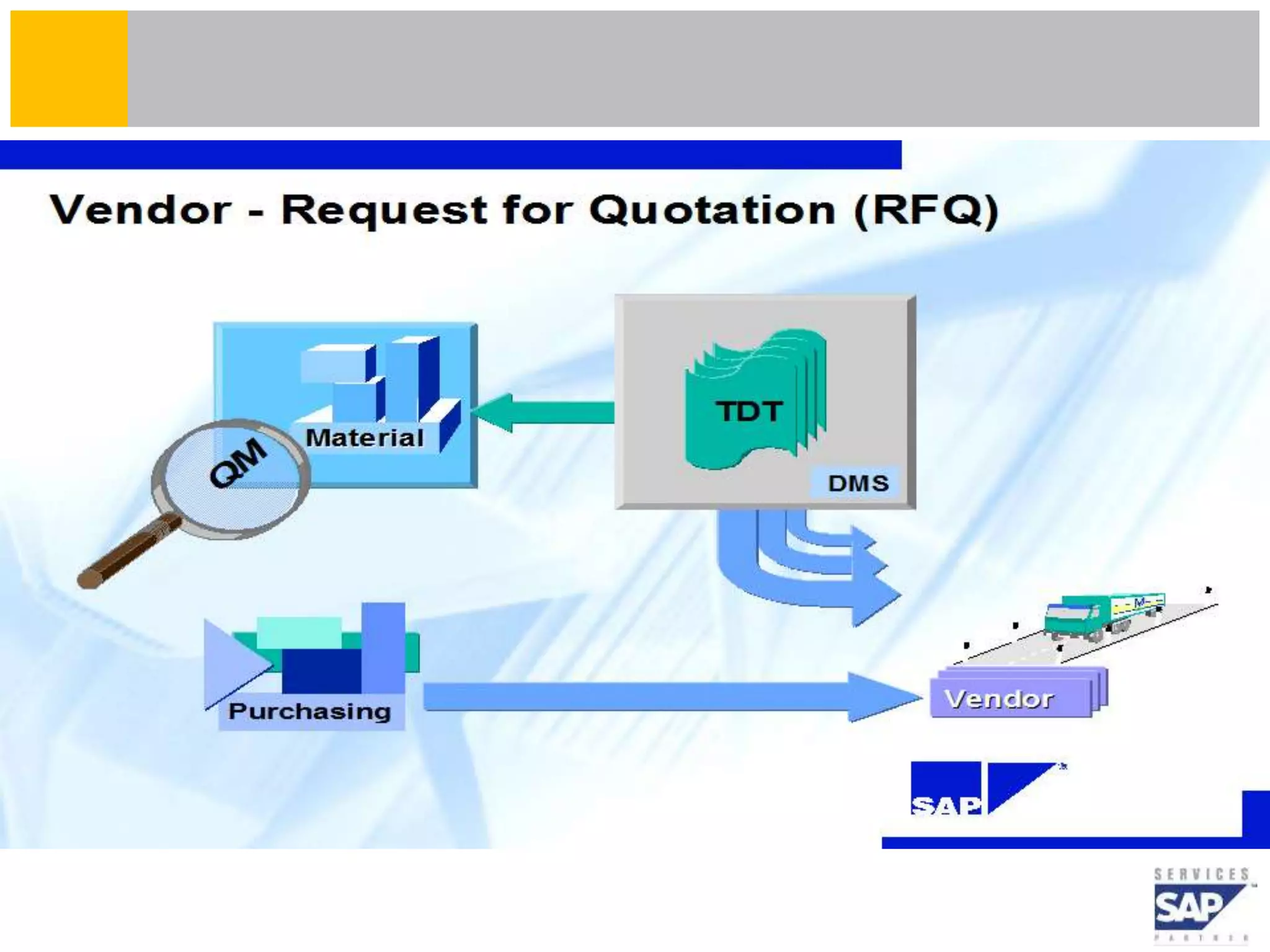

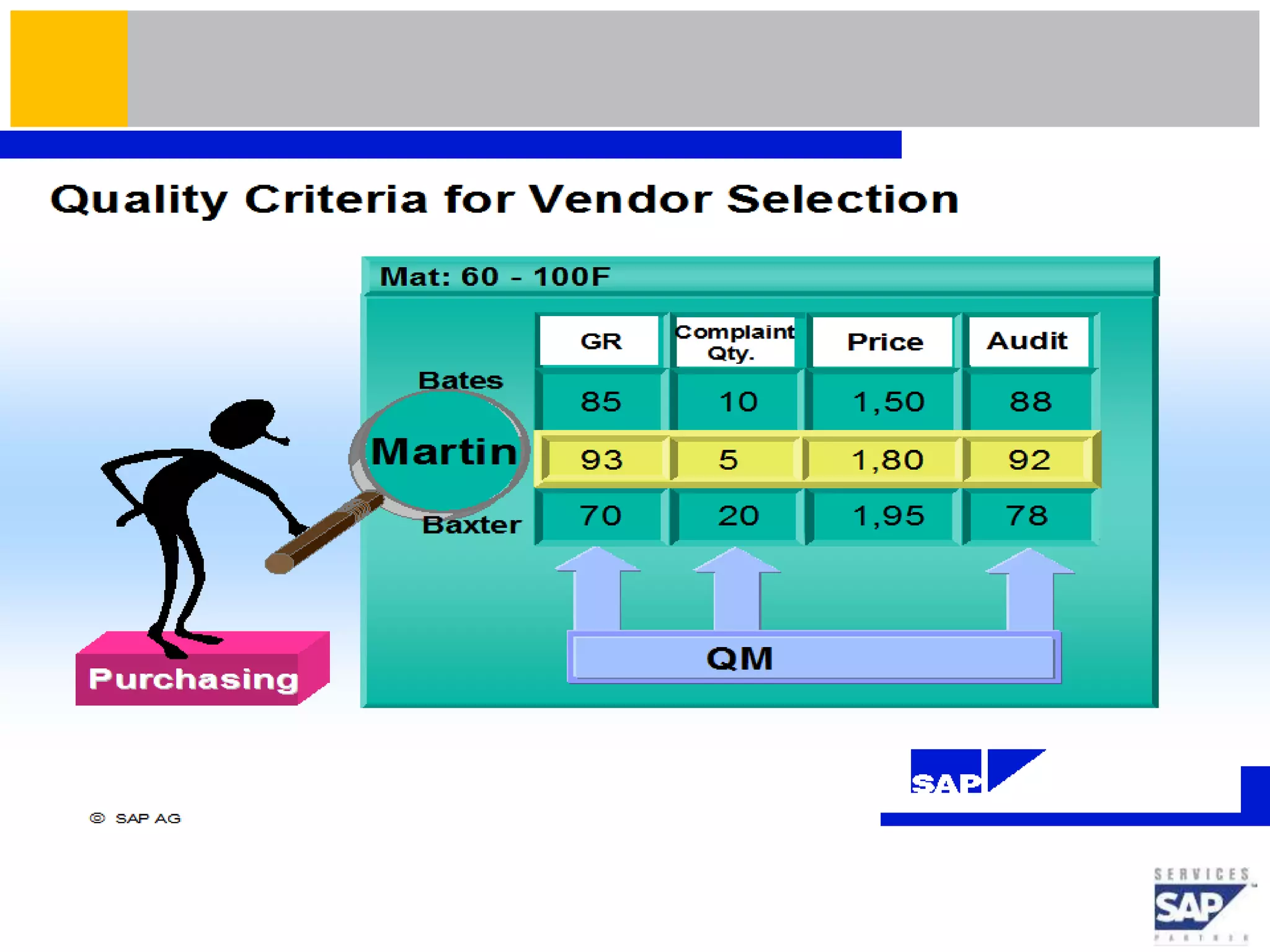

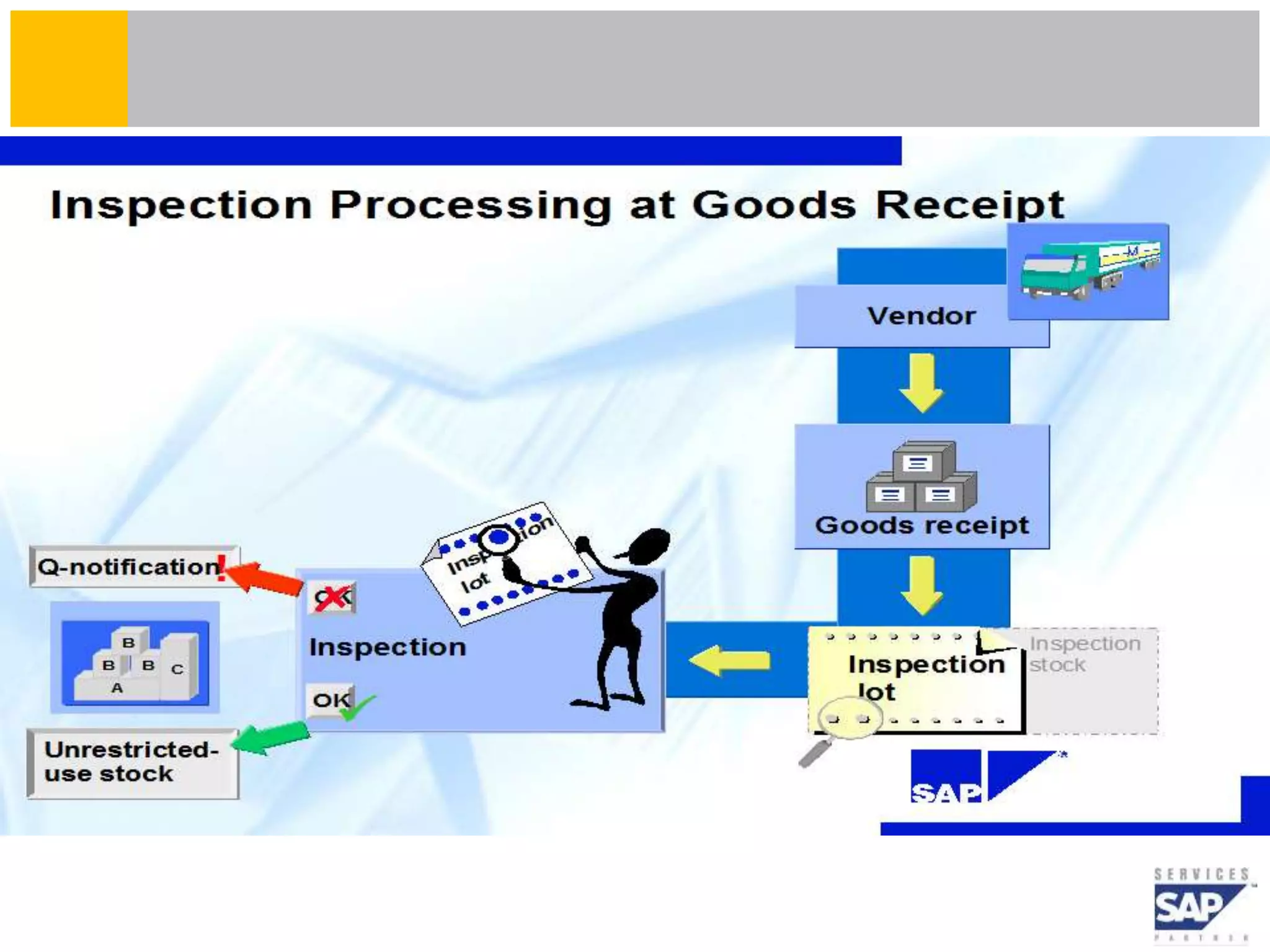

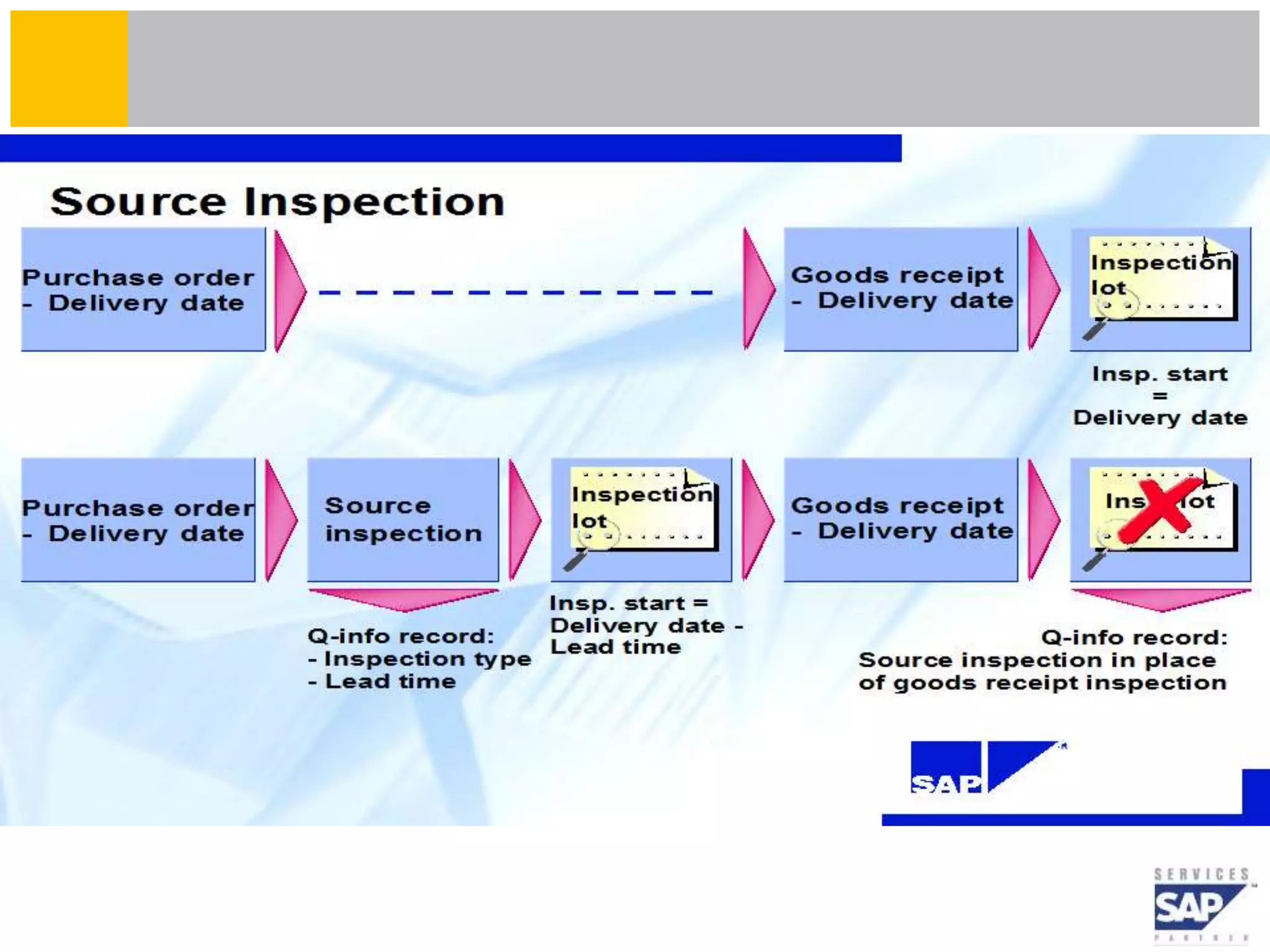

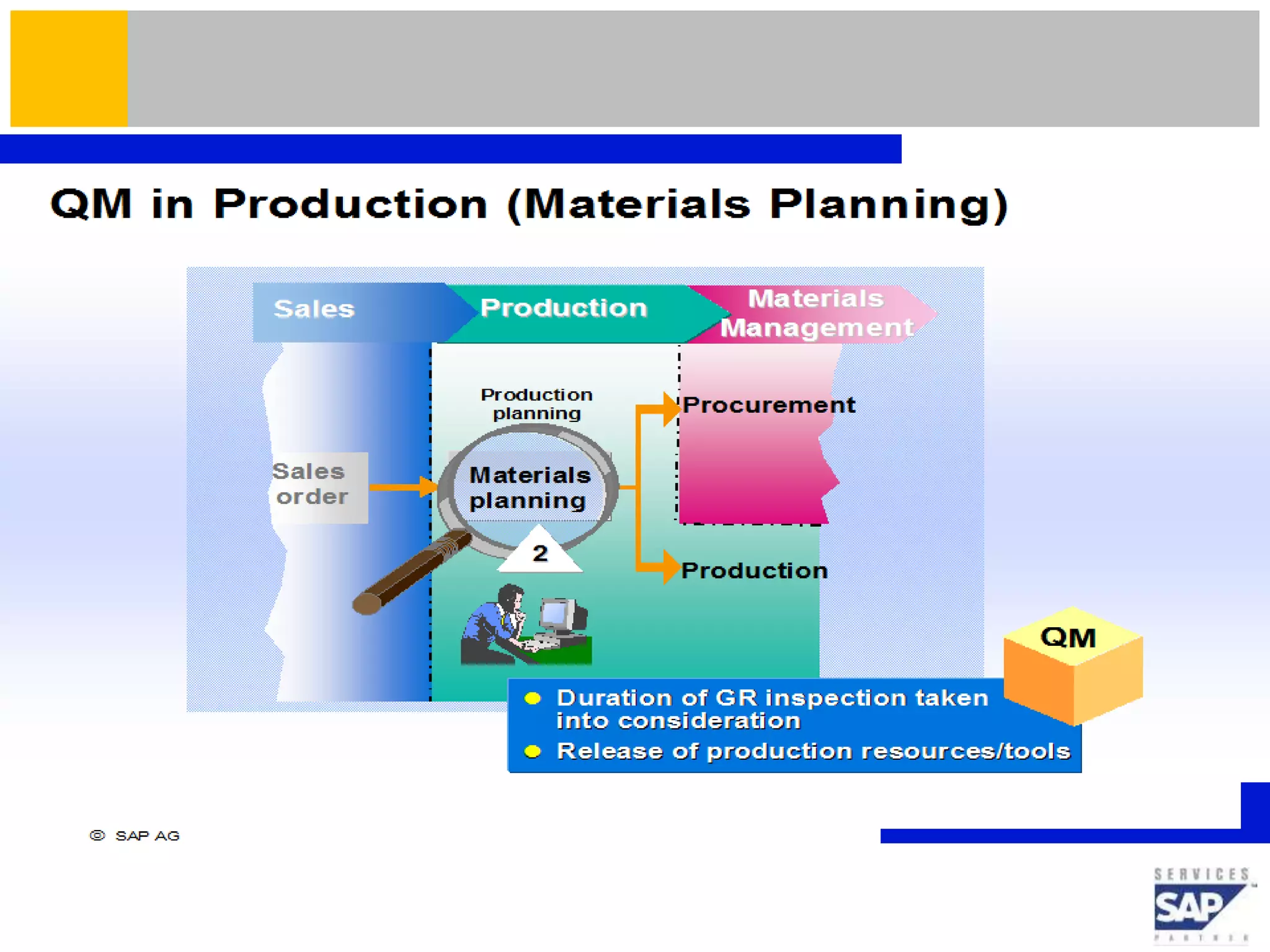

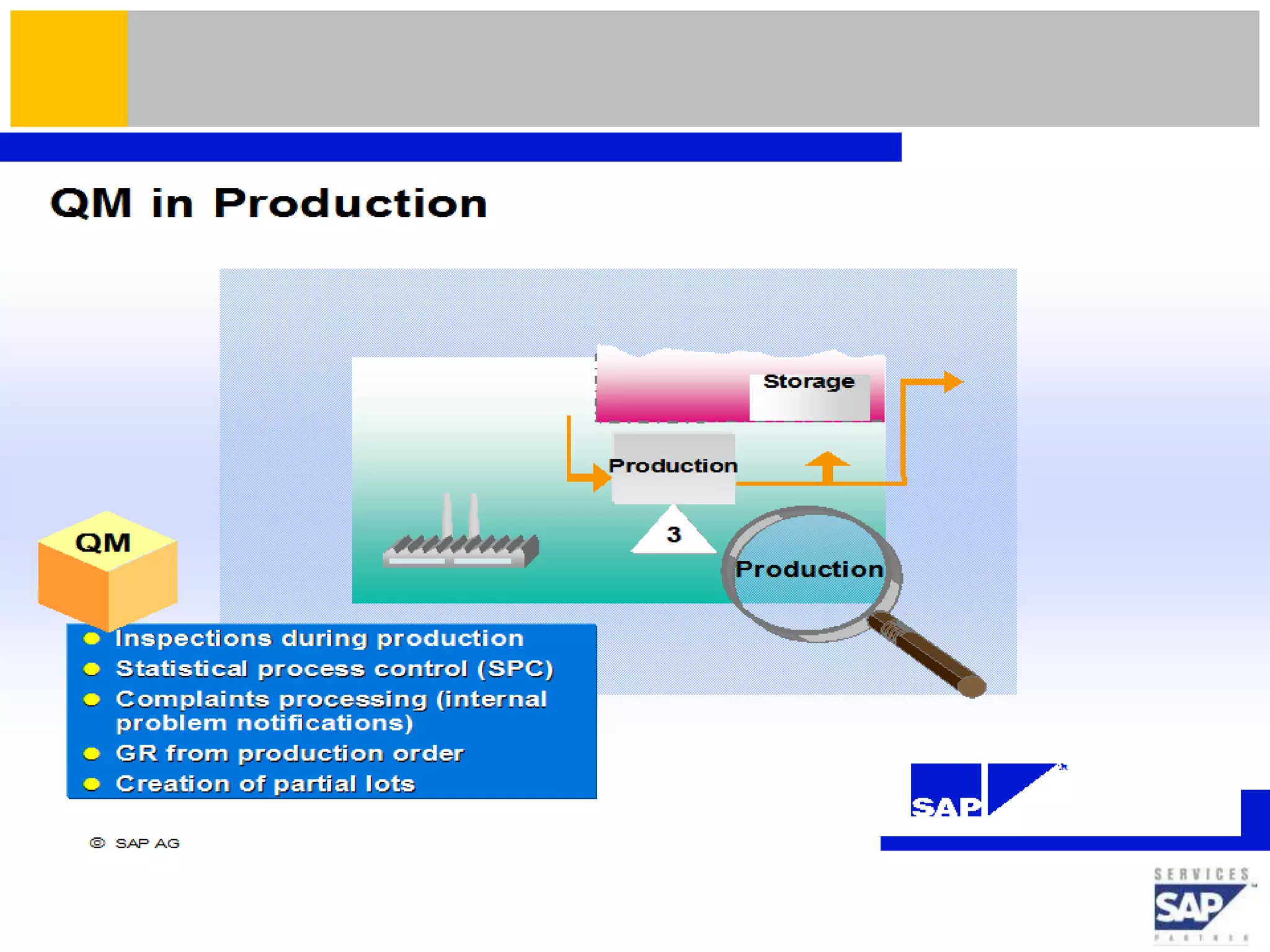

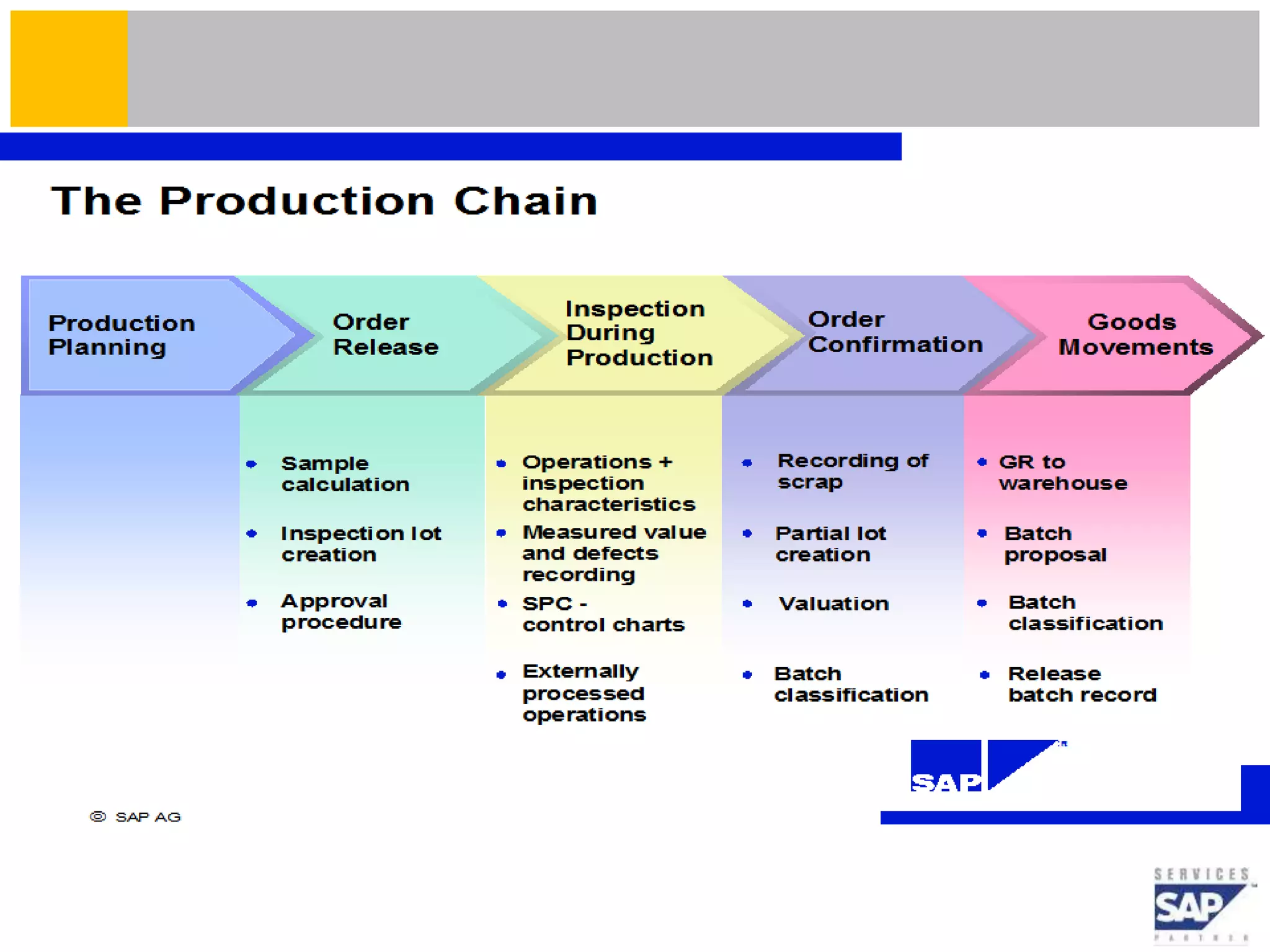

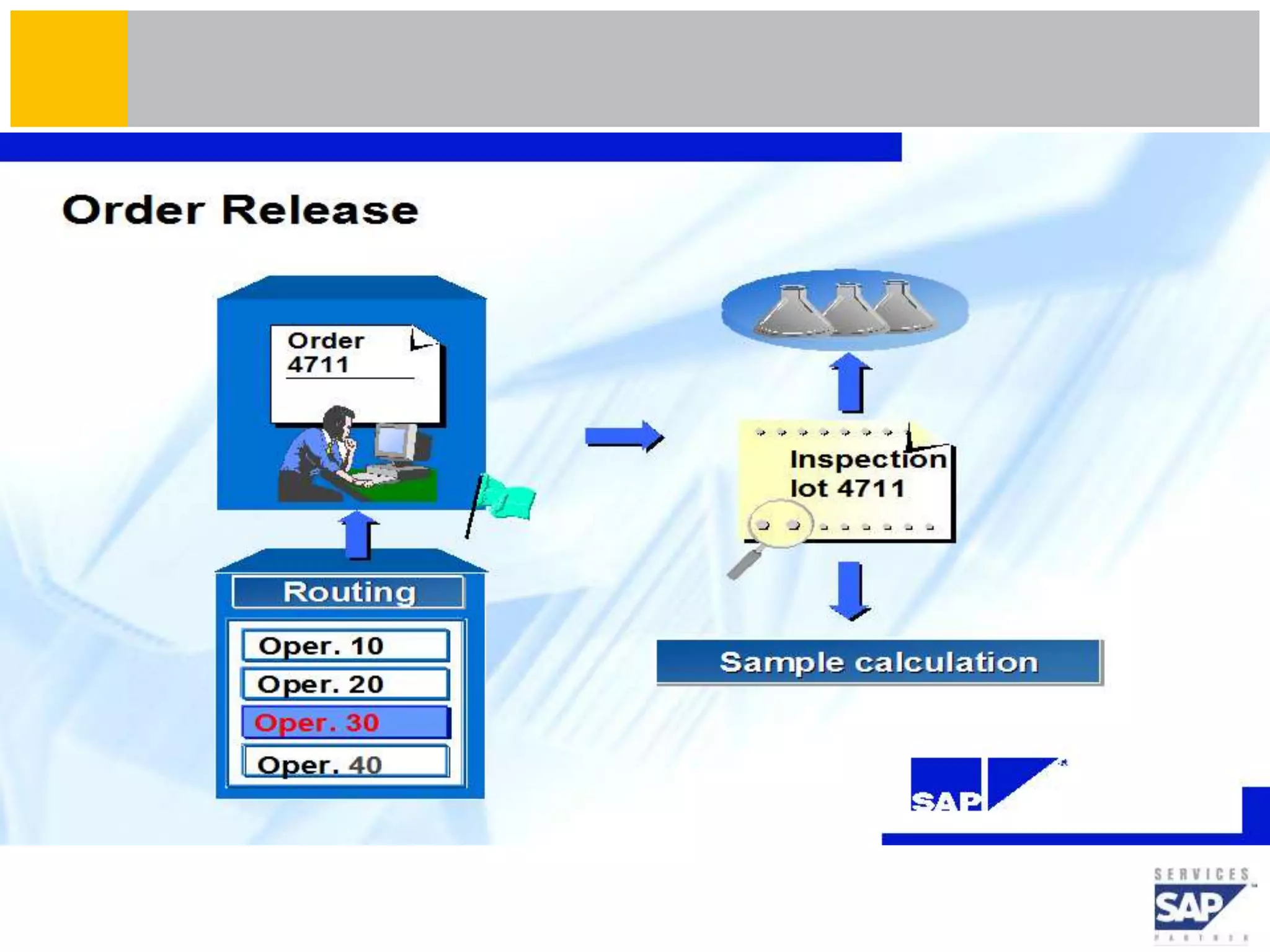

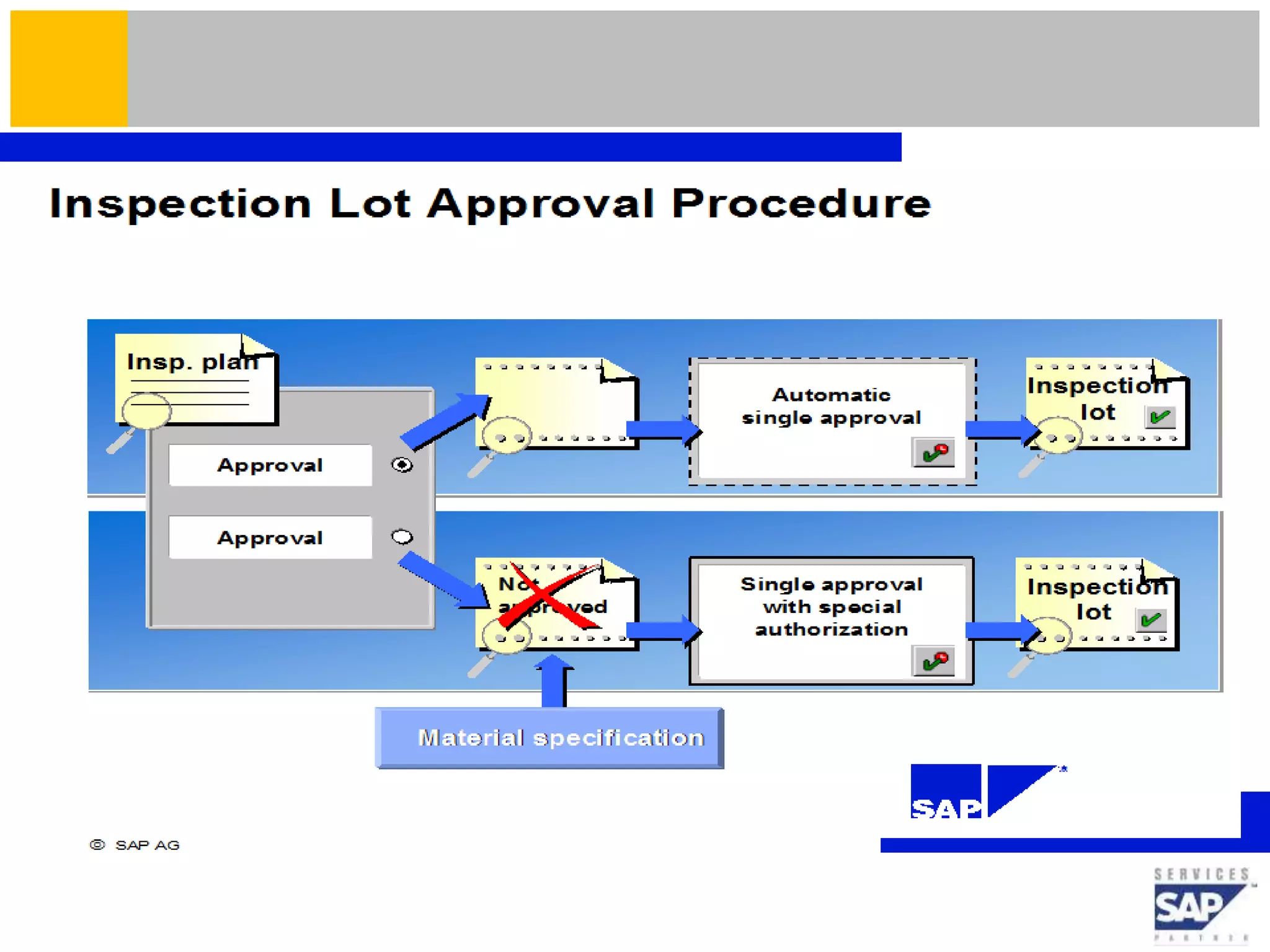

This document provides an overview of SAP's Quality Management (QM) module. It discusses key SAP QM terminologies and functions, including: basic master data for inspection planning, quality control functions like statistical process control and quality costs, test equipment management, quality certificates, QM in production and distribution, sales and distribution quality processes, active problem management, quality inspection, use of inspection catalogs, master inspection characteristics, sampling procedures, and sampling schemes. The document aims to explain SAP's quality management organization structure and business processes.