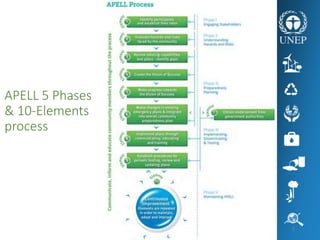

UNEP has several programs to promote plant safety and reduce industrial risks. The APELL program promotes emergency preparedness at the local level through community participation and multi-stakeholder planning. The Flexible Framework provides guidance for governments to develop chemical accident prevention programs nationally. The Responsible Production approach provides guidance and tools for SMEs to improve safety practices along the supply chain. Both programs emphasize adaptability, flexibility, transparency, and collaboration among stakeholders.