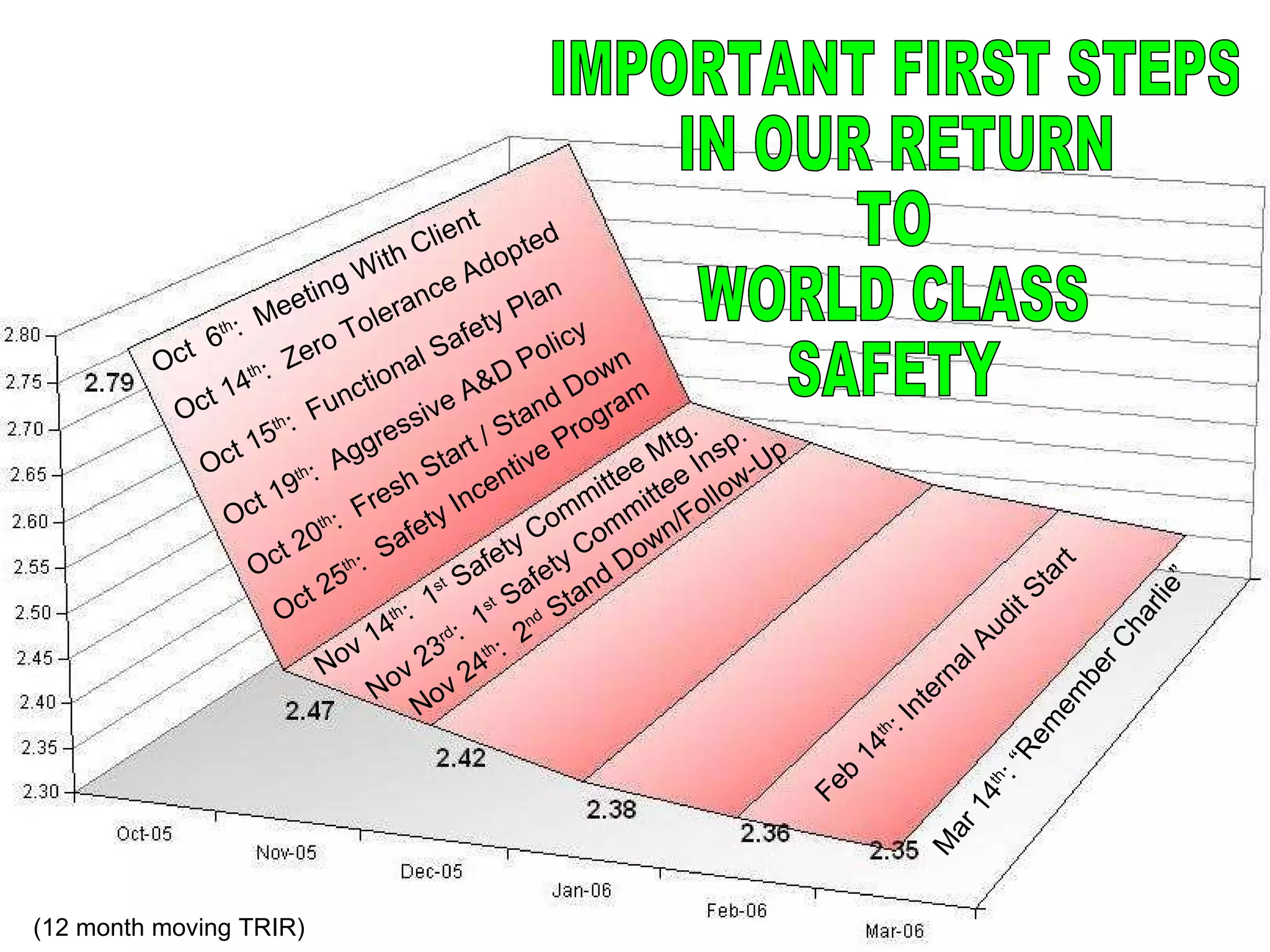

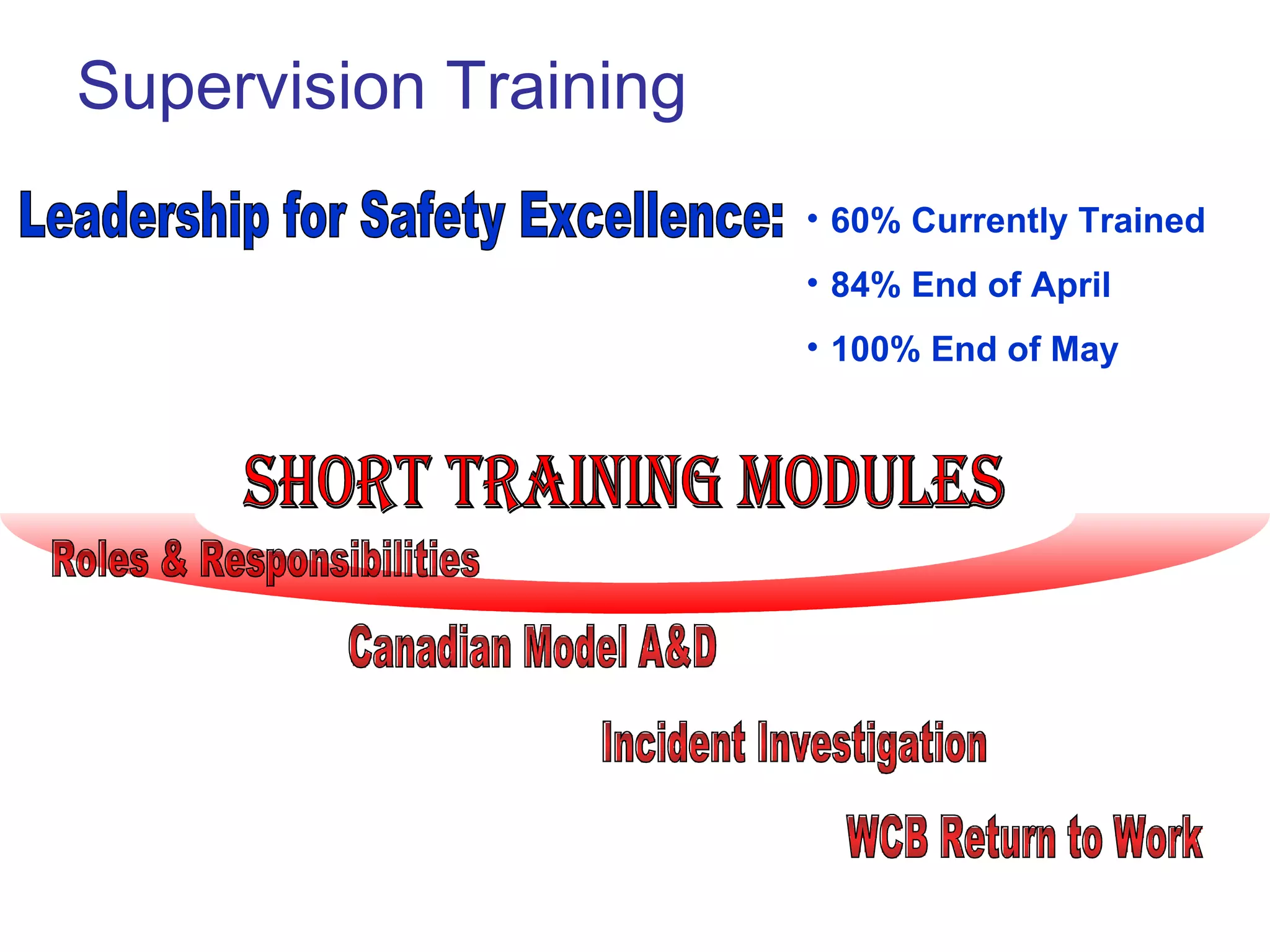

The document outlines safety performance and incident rates for a company from January 2005 to date, noting zero lost time incidents despite several injuries. It details a series of initiatives aimed at improving safety, including aggressive intervention programs, mentorship, and ongoing training for workers related to risk identification and management. Additionally, it discusses the prevalence of incidents among inexperienced workers and emphasizes the importance of behavior-based safety and awareness campaigns.