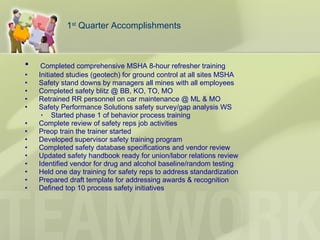

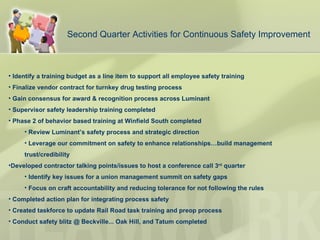

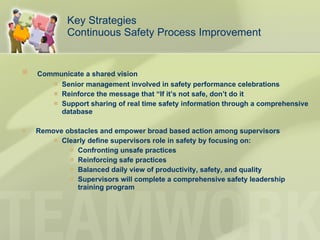

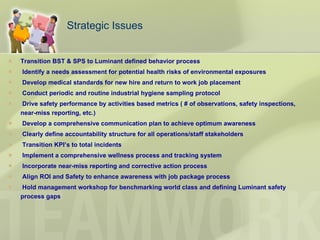

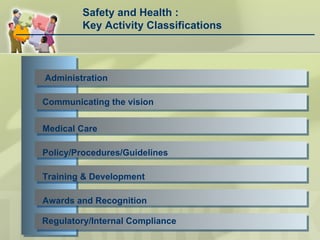

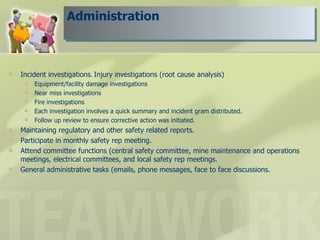

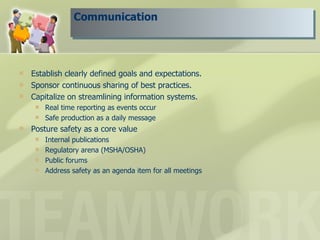

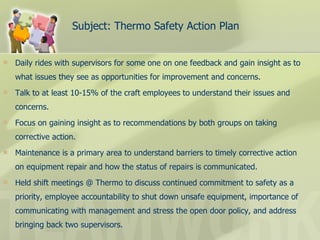

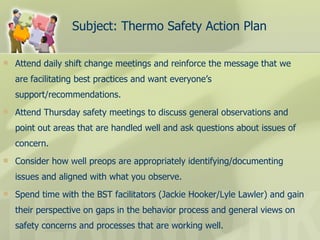

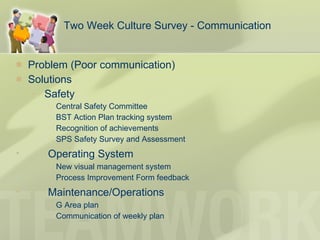

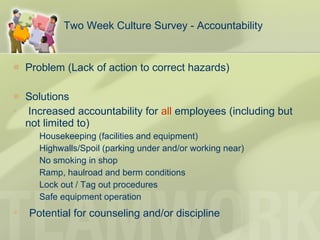

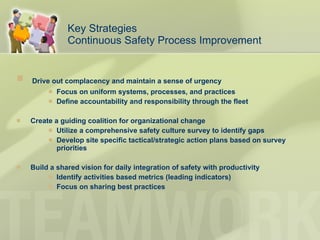

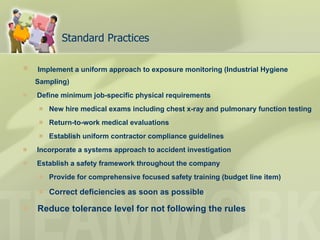

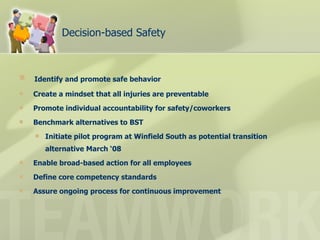

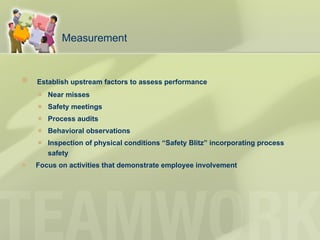

The document outlines safety initiatives and performance at multiple mining sites. It discusses milestones achieved, including periods without injuries. Metrics show improvements in injury rates from the prior year. First quarter accomplishments included training programs. Second quarter activities focused on continuous safety process improvements through strategies like communication, leadership involvement, and standardized practices.