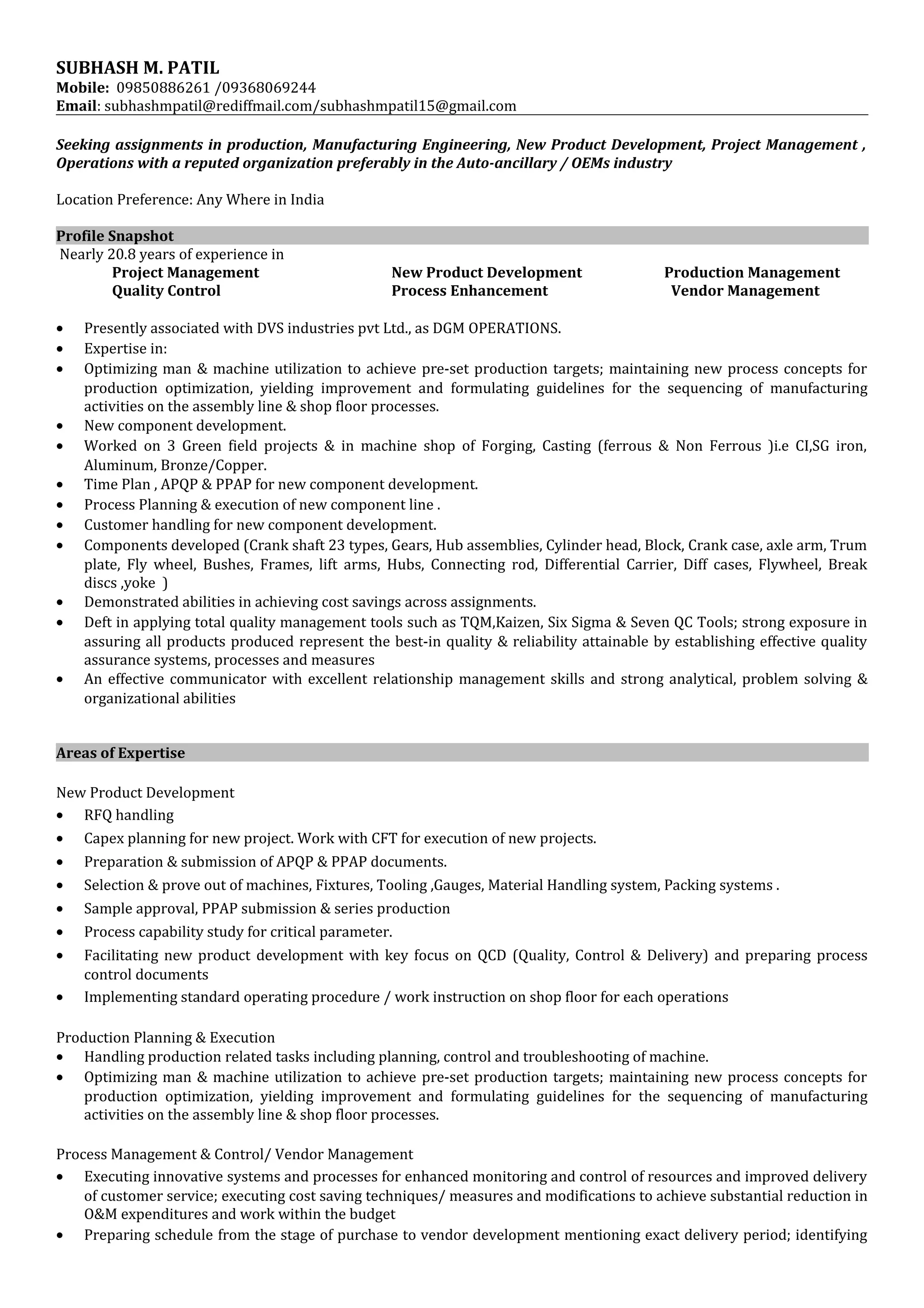

Subhash Patil is seeking a production, manufacturing, or project management role, preferably in the automotive industry. He has over 20 years of experience in areas like new product development, production management, quality control, and process improvement. Currently serving as DGM of Operations at DVS Industries, some of his accomplishments include developing new components, implementing quality systems, and optimizing production.