BIJENDRA CHAUBEY NEW

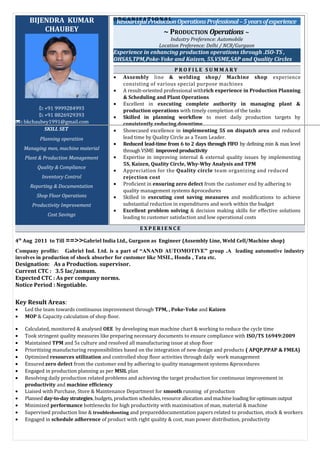

- 1. BIJENDRA KUMAR CHAUBEYA : +91 9999284993 : +91 8826929393 : bkchaubey1991@gmail.com SKILL SET Planning operation Managing men, machine material Plant & Production Management Quality & Compliance Inventory Control Reporting & Documentation Shop Floor Operations Productivity Improvement Cost Savings ResourcefulProductionOperationsProfessional–5yearsofexperience ~ PRODUCTION Operations ~ Industry Preference: Automobile Location Preference: Delhi / NCR/Gurgaon Experience in enhancing production operations through .ISO-TS , OHSAS,TPM,Poke-Yoke and Kaizen, 5S,VSME,SAP and Quality Circles P R O F I L E S U M M A R Y • Assembly line & welding shop/ Machine shop experience consisting of various special purpose machines • A result-oriented professional withrich experience in Production Planning & Scheduling and Plant Operations • Excellent in executing complete authority in managing plant & production operations with timely completion of the tasks • Skilled in planning workflow to meet daily production targets by consistently reducing downtime • Showcased excellence in implementing 5S on dispatch area and reduced lead time by Quality Circle as a Team Leader. • Reduced lead-time from 6 to 2 days through FlFO by defining min & max level throughVSME improvedproductivity • Expertise in improving internal & external quality issues by implementing 5S, Kaizen, Quality Circle, Why-Why Analysis and TPM • Appreciation for the Quality circle team organizing and reduced rejection cost • Proficient in ensuring zero defect from the customer end by adhering to quality management systems &procedures • Skilled in executing cost saving measures and modifications to achieve substantial reduction in expenditures and work within the budget • Excellent problem solving & decision making skills for effective solutions leading to customer satisfaction and low operational costs O R G A N I S A T I O N A L E X P E R I E N C E 4th Aug 2011 to Till ==>>Gabriel India Ltd., Gurgaon as Engineer (Assembly Line, Weld Cell/Machine shop) Company profile: Gabriel Ind. Ltd. is a part of “ANAND AUTOMOTIVE” group .A leading automotive industry involves in production of shock absorber for customer like MSIL, Honda , Tata etc. Designation: As a Production. supervisor. Current CTC : 3.5 lac/annum. Expected CTC : As per company norms. Notice Period : Negotiable. Key Result Areas: • Led the team towards continuous improvement through TPM, , Poke-Yoke and Kaizen • MOP & Capacity calculation of shop floor. • Calculated, monitored & analysed OEE by developing man machine chart & working to reduce the cycle time • Took stringent quality measures like preparing necessary documents to ensure compliance with ISO/TS 16949:2009 • Maintained TPM and 5s culture and resolved all manufacturing issue at shop floor • Prioritizing manufacturing responsibilities based on the integration of new design and products ( APQP,PPAP & FMEA) • Optimized resources utilization and controlled shop floor activities through daily work management • Ensured zero defect from the customer end by adhering to quality management systems &procedures • Engaged in production planning as per MSIL plan • Resolving daily production related problems and achieving the target production for continuous improvement in productivity and machine efficiency • Liaised with Purchase, Store & Maintenance Department for smooth running of production • Planned day-to-day strategies, budgets, production schedules, resource allocation and machine loading for optimum output • Minimized performance bottlenecks for high productivity with maximisation of man, material & machine • Supervised production line & troubleshooting and prepareddocumentation papers related to production, stock & workers • Engaged in schedule adherence of product with right quality & cost, man power distribution, productivity

- 2. • Daily Maintenance of below records: a) Daily plan cum production report., Hourly production monitoring b) Daily rejection report, Line rejection report. c) Quality check sheet, Opening check sheet. • Attended field complaints and implemented POKA-YOKEs to avoid problem in future • Having skills to increase human productivity,machine roductivity and line efficiency • Identified and analysed the production gap and improve the overall efficiency • Procured new machines as per product requirement and reducing time by applying , SMED • Controlled the safety measure by identifying the unsafe work conditions • Motivatedemployees through team building and training • Managing men, machine and material on the shop floor as per production plan. Highlights: • Best OE of The Month (two times). • Winning Quality circle at plant level, zone level and at National level • Got awarded by Rs. 7,000 in Kaizen competition • Implemented 45 Kaizen out of suggested 62 Kaizen (my own) with in six month. • Imparted on-the job training to new operators as a Leader of KAIZEN and Suggestion Team • Reduced 3 manpower in assembly area along with lead time from 59 days to 36 days (Value Stream Mapping) • Played a key role in reducing N.VA. Activities • Implemented FIFO system in shop floor • Having knowledge of HEIJUNKA PRODUCTION SYSTEMS (HPS) • Reduce changeover time 35min. To 10min. In Assembly ,forging ,cnc shops. • Pivotal in streamlining processes through measures such as 5s, training, teamwork and problem solving tools, • Controlled PPM level from 15/000 PPM to <5/000 PPM in-house by implementing modification in tooling of seam welding by implemention of various POKA-YOKA, & 7Q.C Tool. T R A I N I N G S • SAP • A- star • I SO-TS,OHSAS • Quality Circle ,TPM • 5S, Basic MOST and Safety from Anand University, Parwanoo,HPS ,AHPS, VSME • Trainning on SMED,POKA –YOKA • Trainning In QRQC,SPC,JIT,7Q.C Tool, • Data collection & Problem Solving • Communication skill,Presentation • Soft Skills (Team Building, Conflict Management, First Time Leaders) A C A D E M I C D E T A I L S 2015 B.Tech. (Mechanical) from Karnataka Stste of Open University . 2011 Diploma in Mechanical Engineering from lovely professional University punjab 2006 10th from government added heigh school kateya gopalganj biihar I T S K I L L S • Sap.Auto CAD, MS Office and Internet Applications E X T R A C U R R I C U L A R A C T I V I T I E S • Acted as Member of NCC, Main Player of Cricket & Volley Ball or Athelatich Raccer at Compny $ College Level and won several tournaments P E R S O N A L D E T A I L S Father’s Name: Late Sh. Mahima chaubey Date of Birth: 6th march 1991

- 3. Address: Vill-Jaiswaly,Post-Kateya,Dist-Gopalganj,State-Bihar,Pincode-841437 Languages Known: English & Hindi Nationality: Indian Marital Status: Unmarried