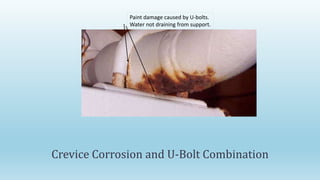

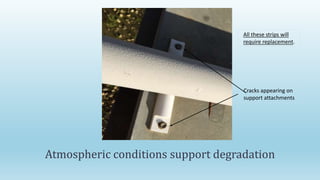

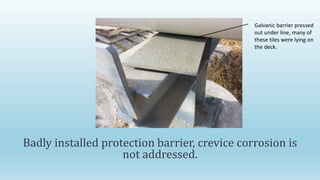

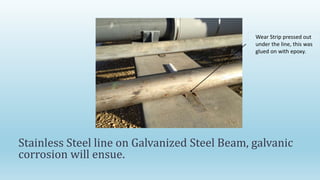

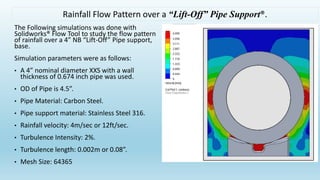

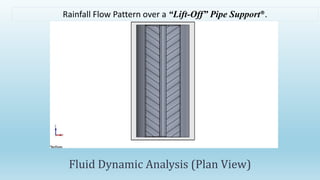

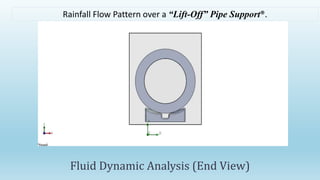

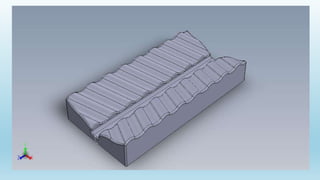

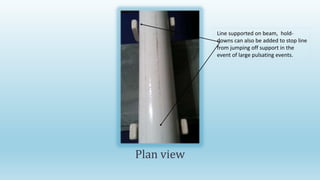

The document discusses the 'lift-off' pipe supports developed by 500 Projects LLC, designed to mitigate issues like crevice corrosion and enhance fluid drainage in piping systems. It highlights the innovative design that increases the load area, reduces stress on coatings, and eliminates the need for hot work during installation. Additionally, the document provides technical specifications and information on testing, materials, and the company's global presence.