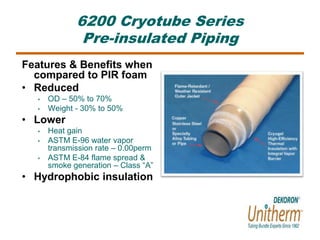

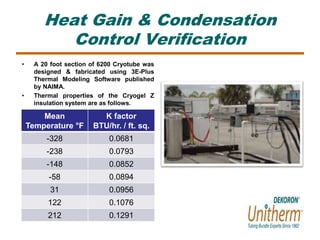

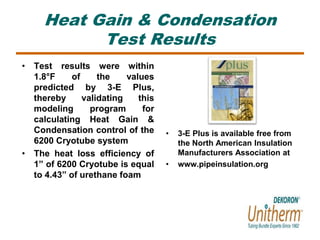

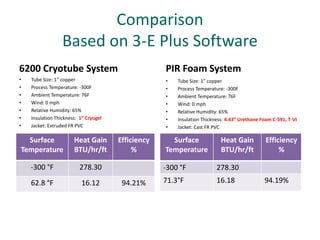

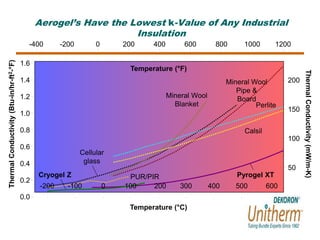

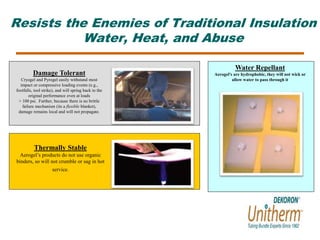

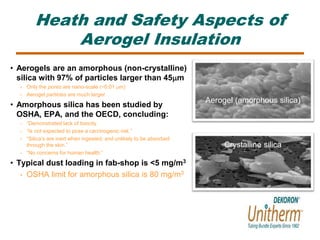

This document describes Dekoron-Unitherm's 6200 Cryotube Series pre-insulated cryogenic piping. It uses aerogel insulation which reduces outer diameter by 50-70% compared to traditional PIR foam, improving piping installation. The aerogel provides better insulation with lower heat gain and moisture transmission. Thermal modeling shows the Cryotube piping performs similarly to thicker PIR foam piping with lower costs, easier installation, and maintenance-free operation.