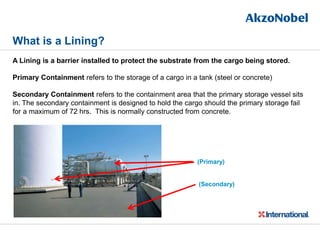

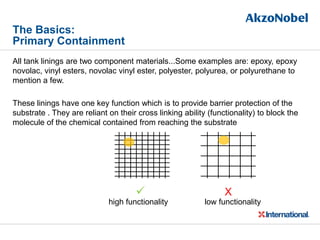

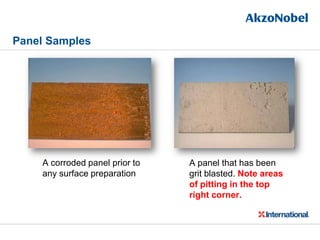

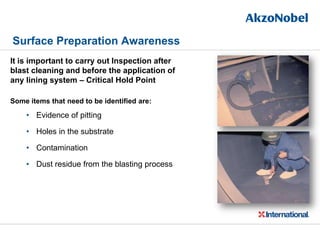

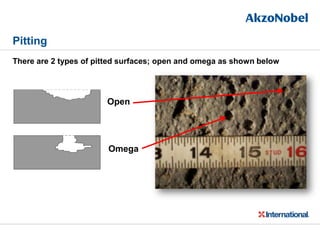

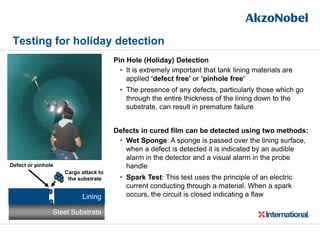

The document introduces linings by International Paint, detailing their function as protective barriers for substrates in various industrial applications. It covers the types of linings, proper selection, surface preparation, application methods, and safety measures when working in confined spaces. Additionally, it emphasizes the importance of testing and maintenance for lining systems to ensure long-lasting performance.