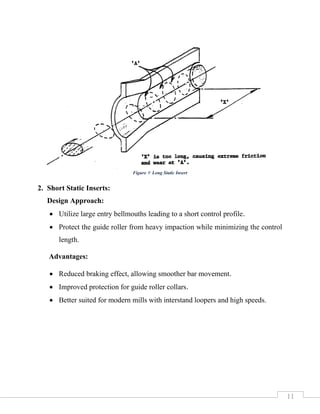

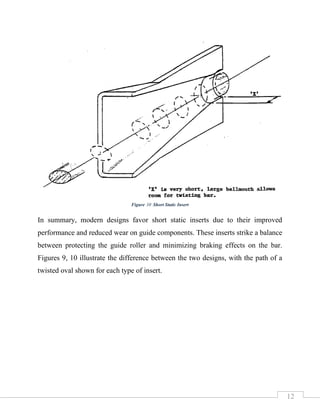

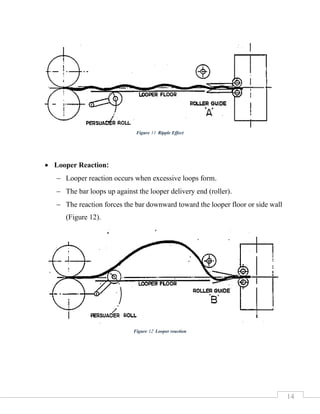

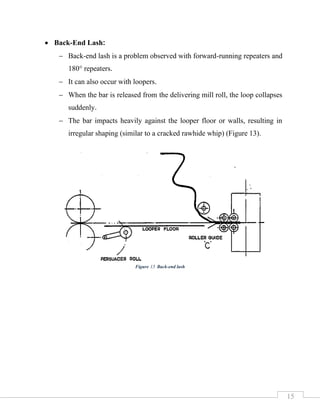

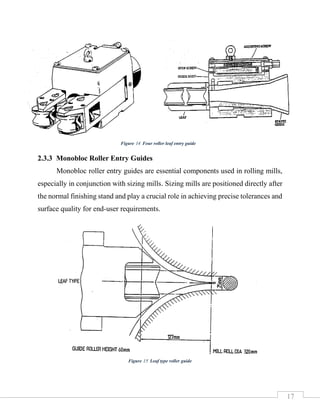

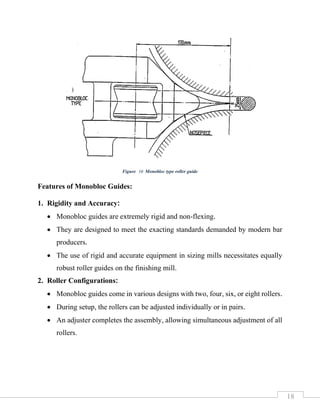

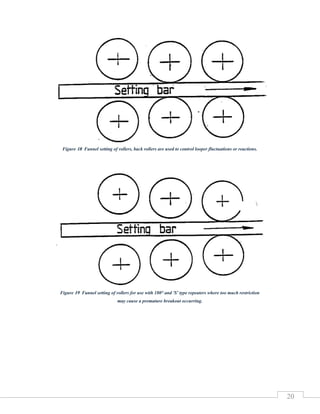

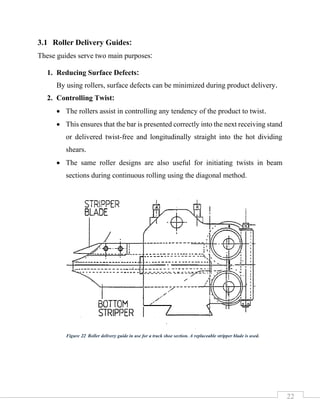

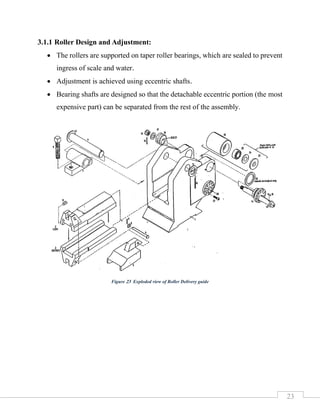

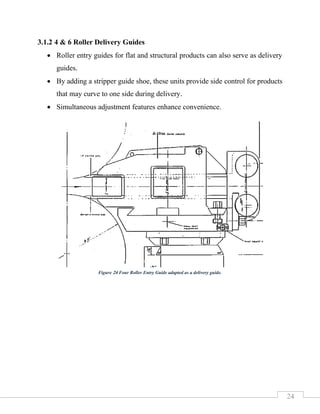

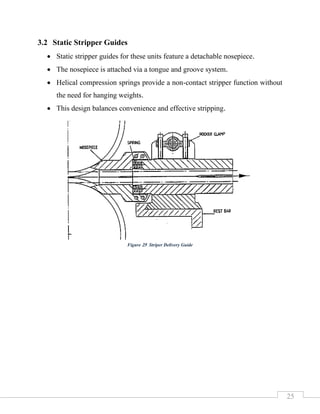

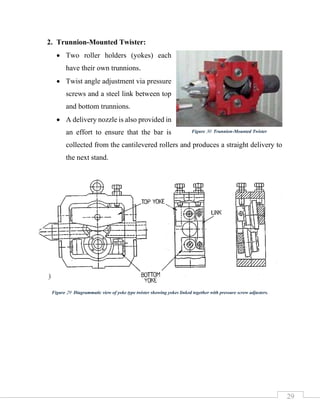

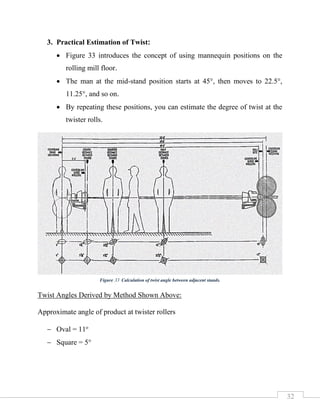

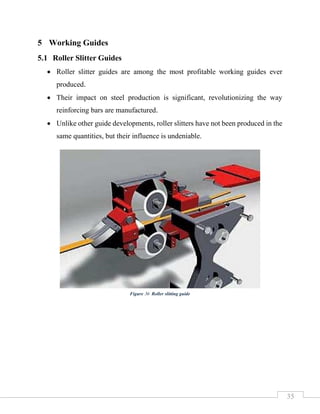

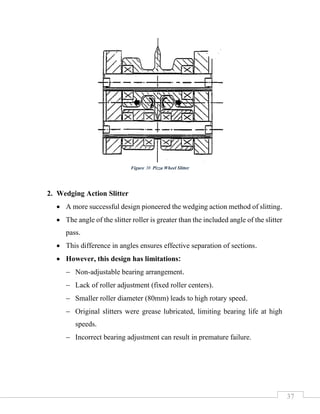

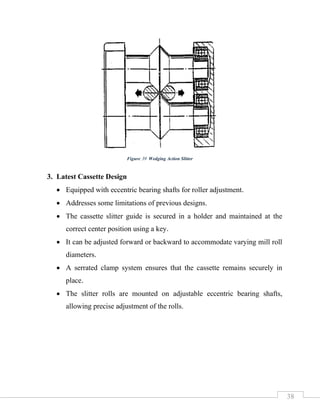

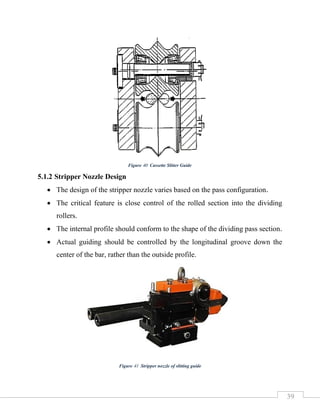

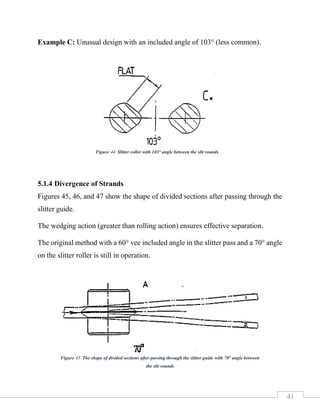

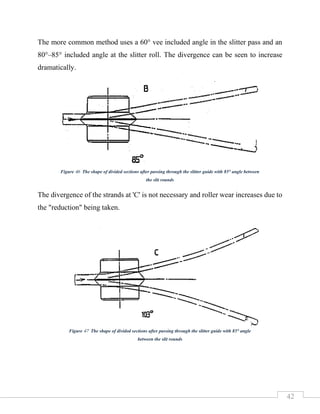

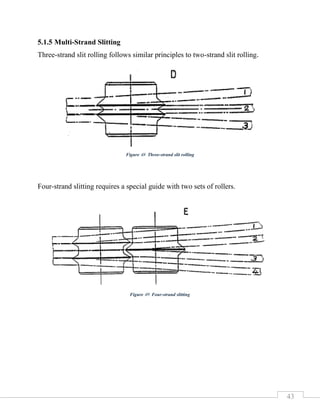

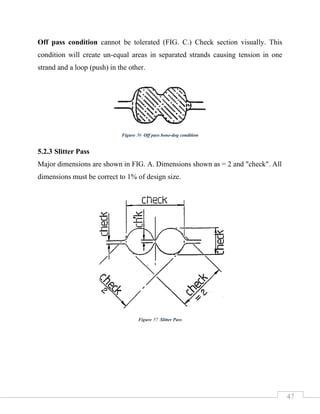

The document is a comprehensive guide on rolling mill guide equipment, detailing various types such as entry guides, delivery guides, roller twist guides, and working guides. It emphasizes the importance of stability, alignment, and material selection for ensuring smooth rolling processes and high-quality end products. Each guide type is explained in terms of design, function, and the challenges faced in their usage within modern steel production contexts.