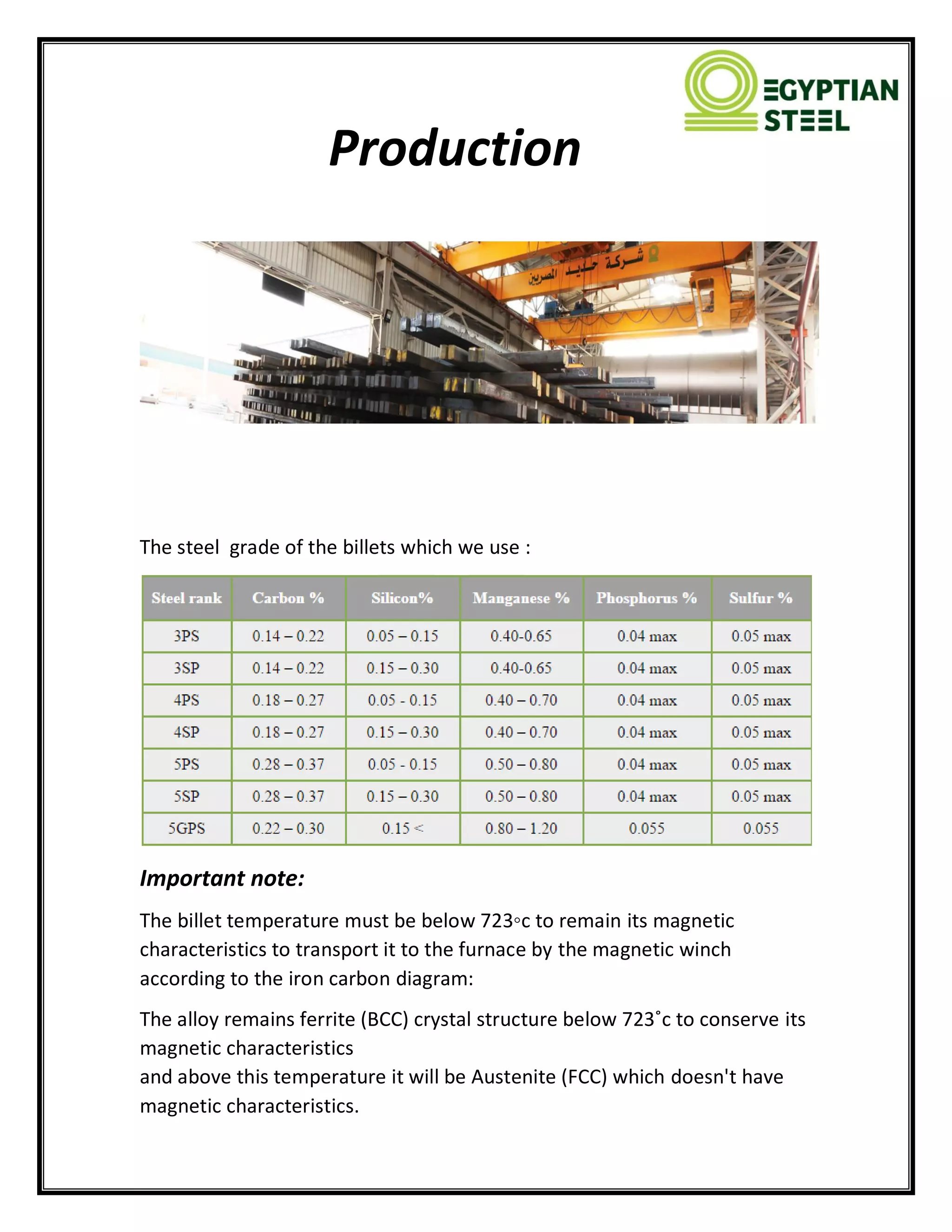

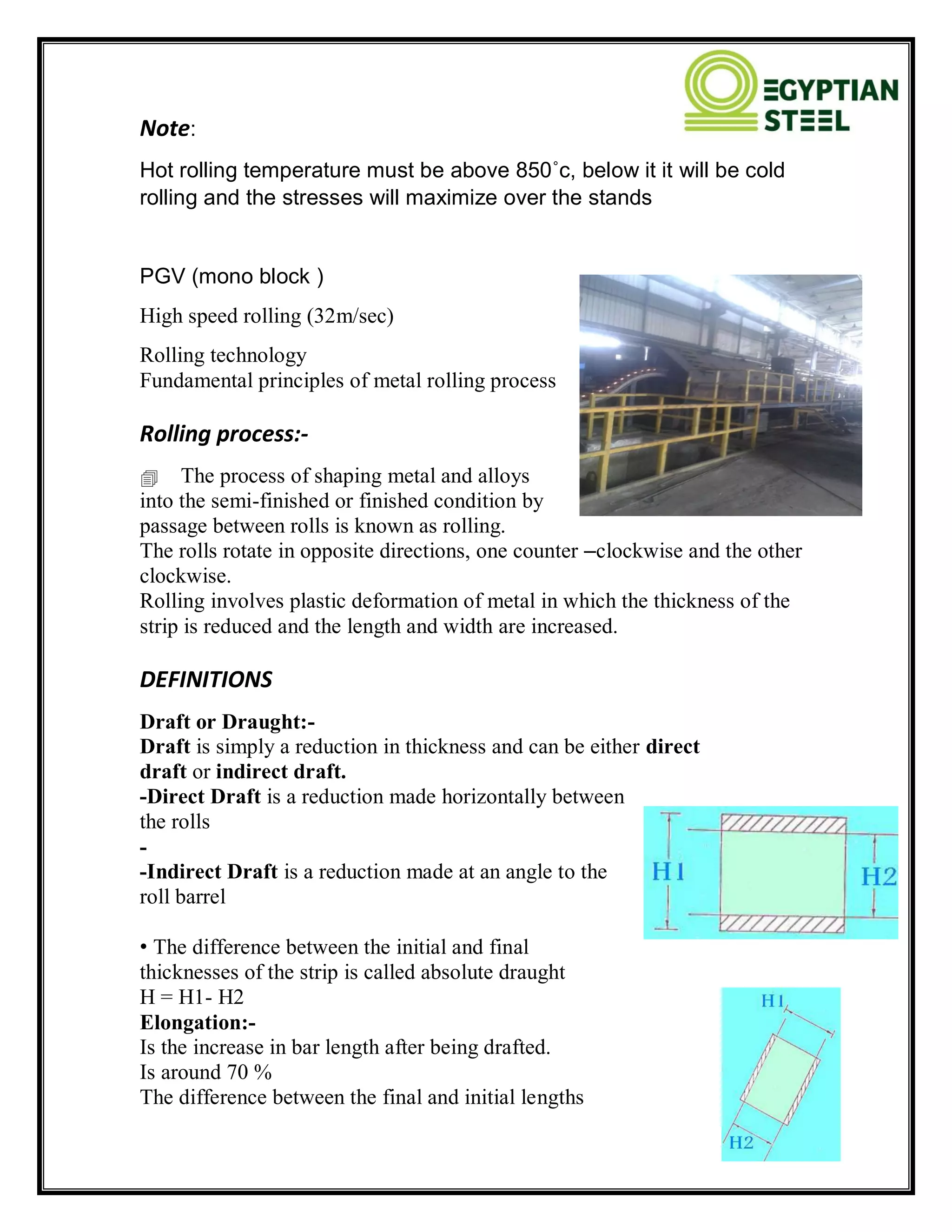

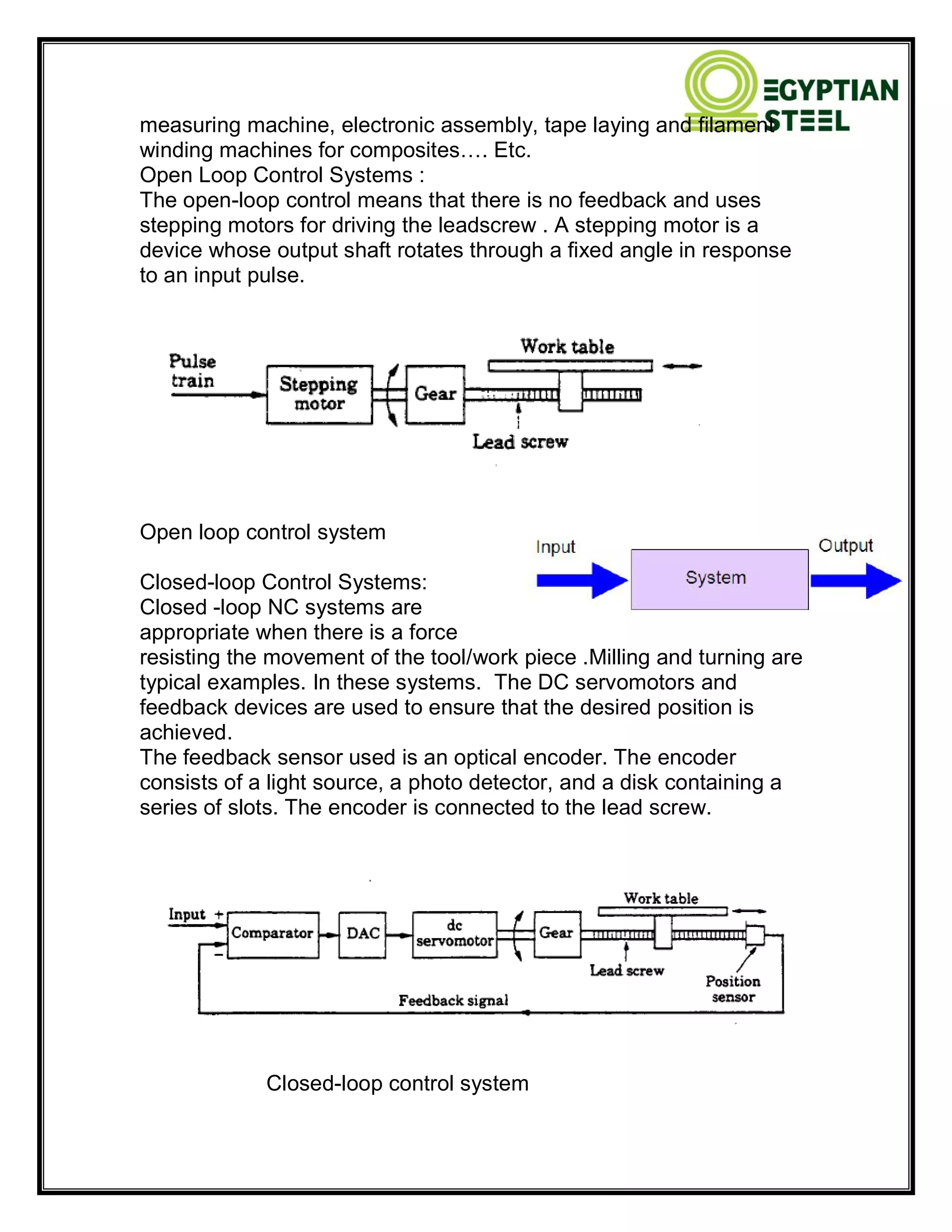

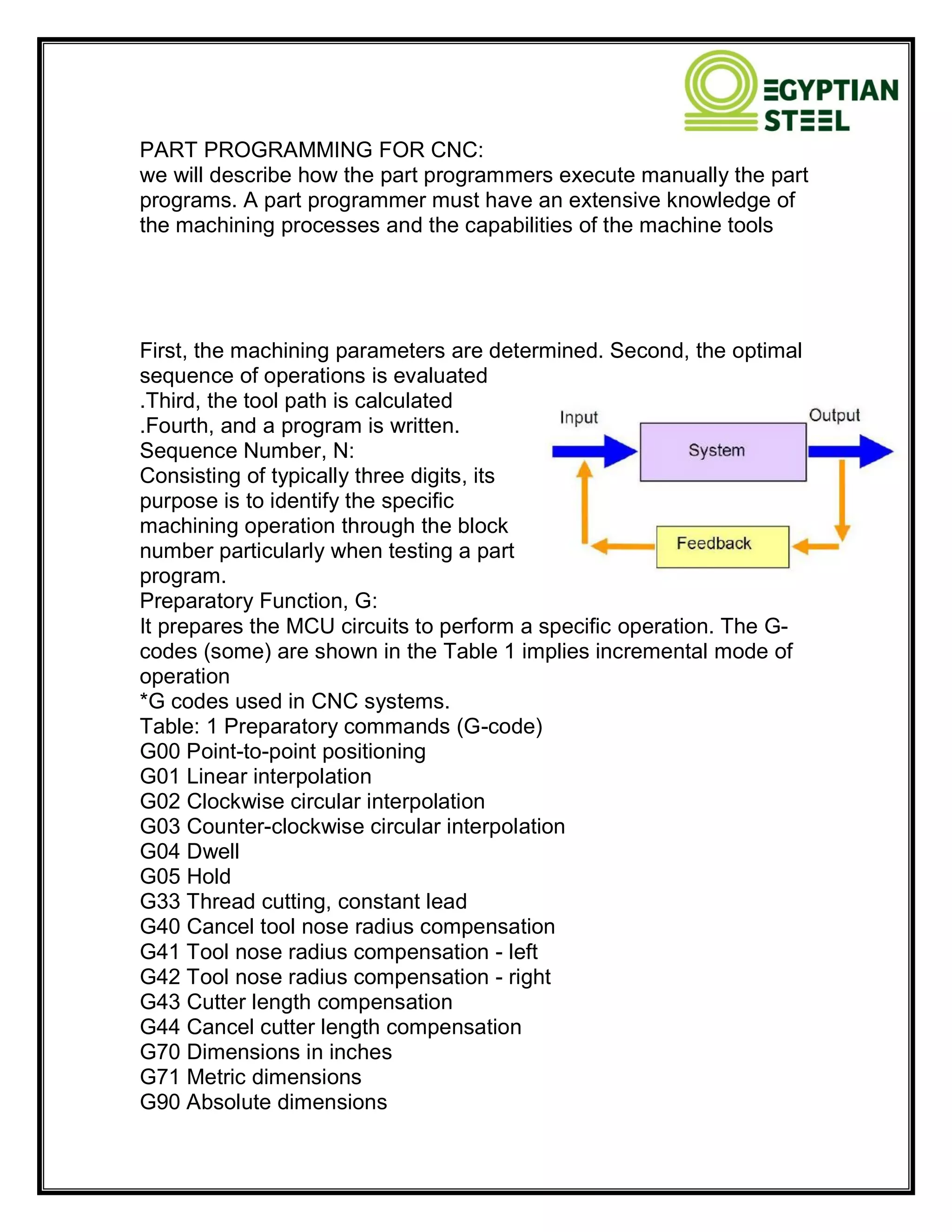

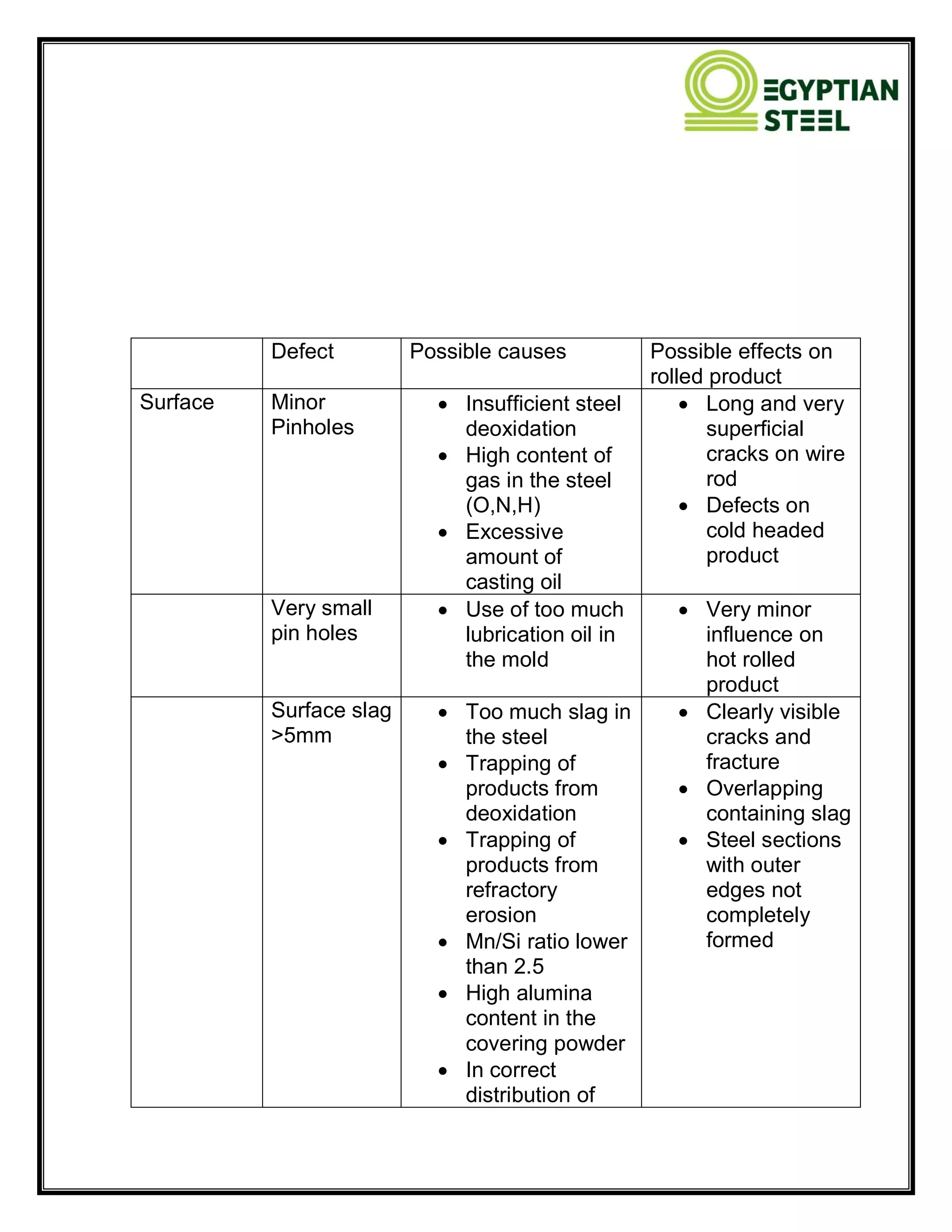

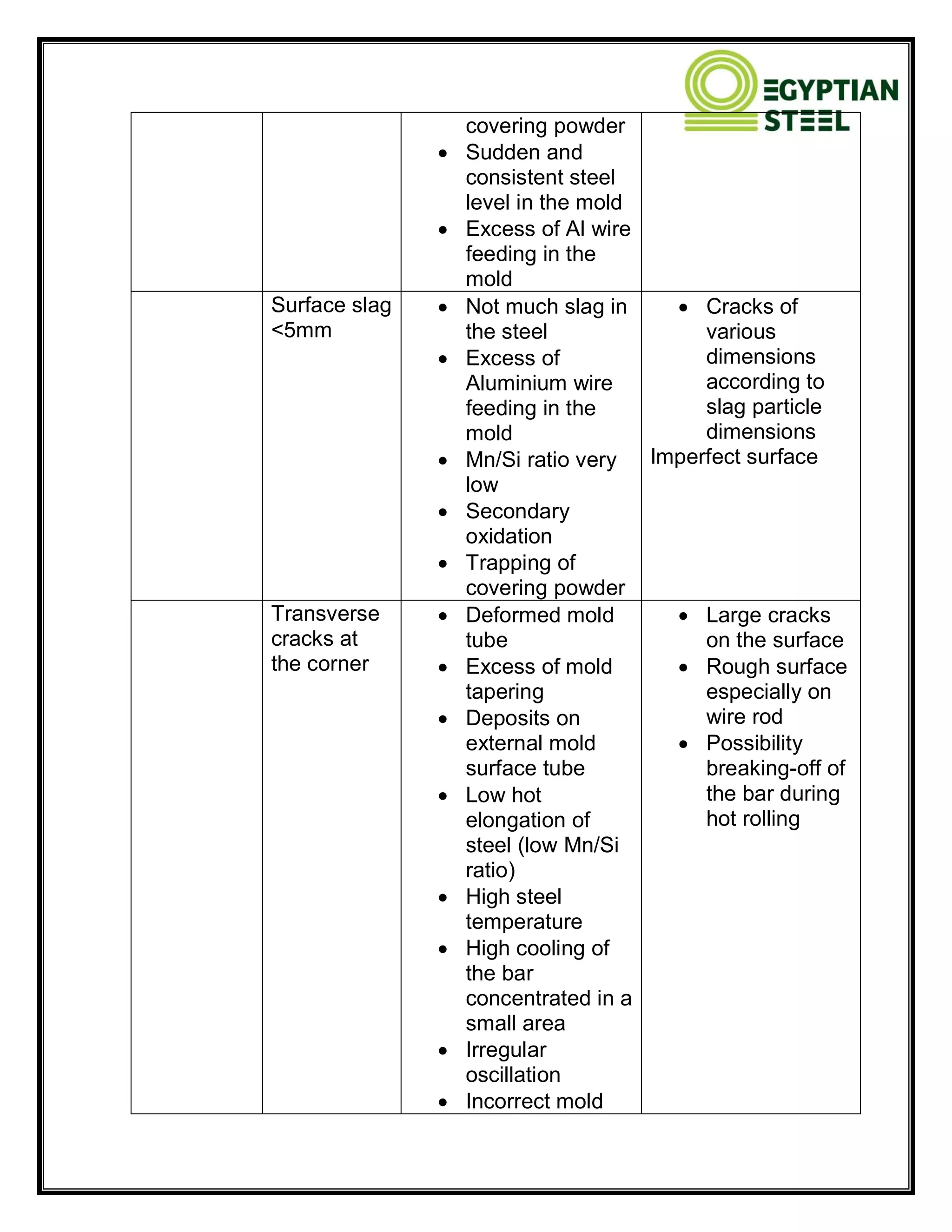

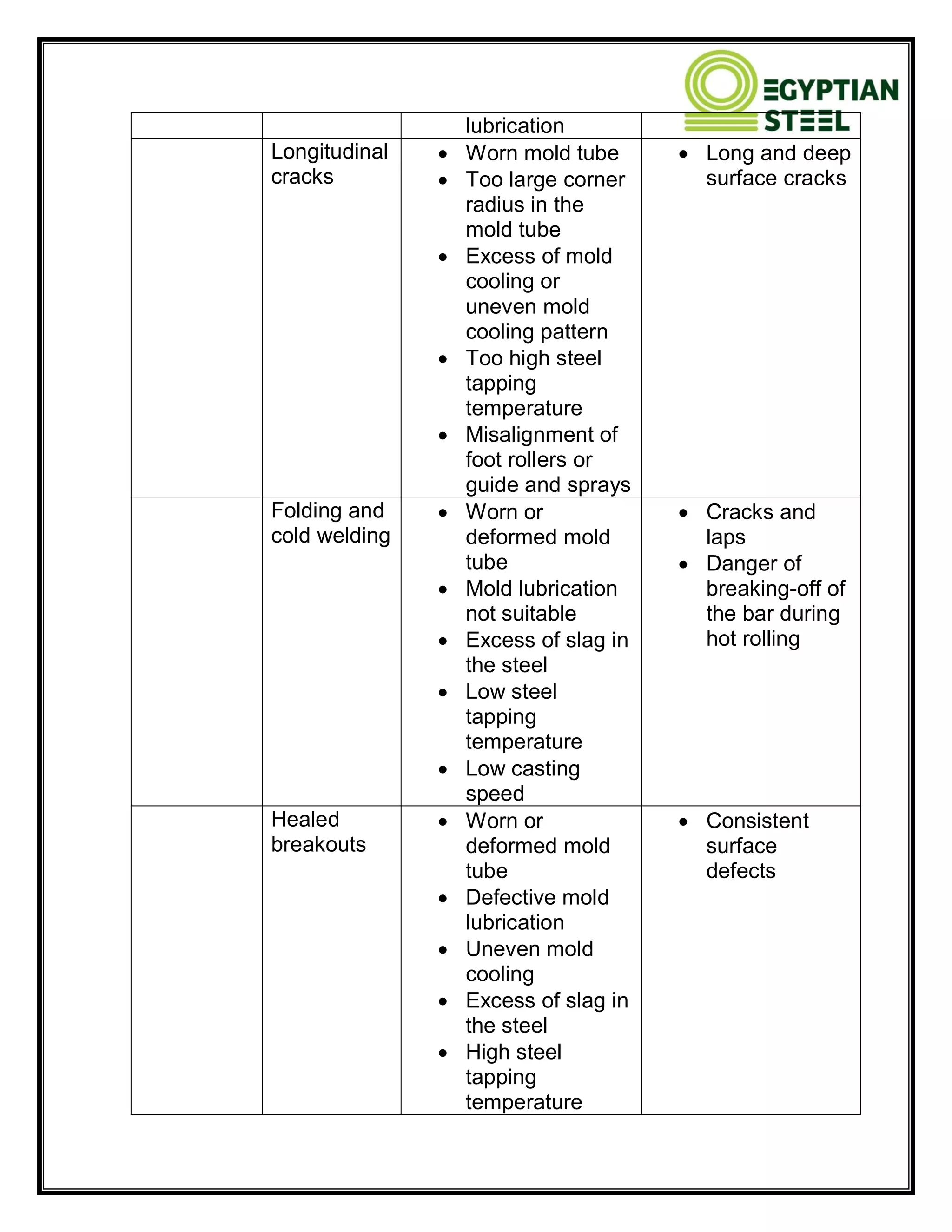

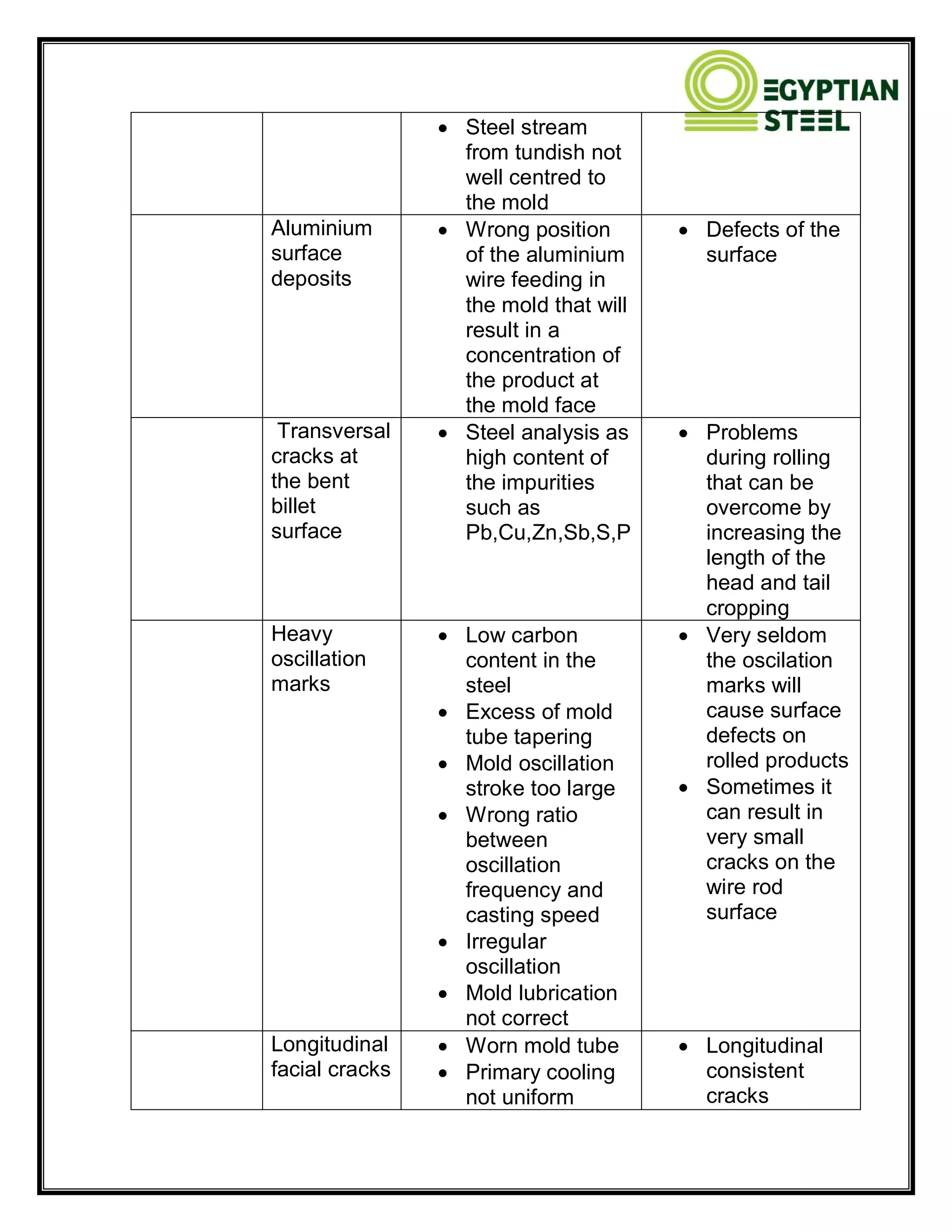

This training report summarizes production, workshop, and quality control processes at an Egyptian steel factory. It discusses the steel grades used, reheating furnace operations, rolling processes across 22 stands to produce wire rod and rebar, workshop functions including CNC machining, and quality control procedures for inspecting billets and final coil products. Key points covered include maintaining billet temperature below 723°C for magnetic transport, 14 burners in the reheating furnace heating billets to 1230-1250°C, and inspecting billets for surface defects like pinholes, slag, and cracks that could affect the rolled product.