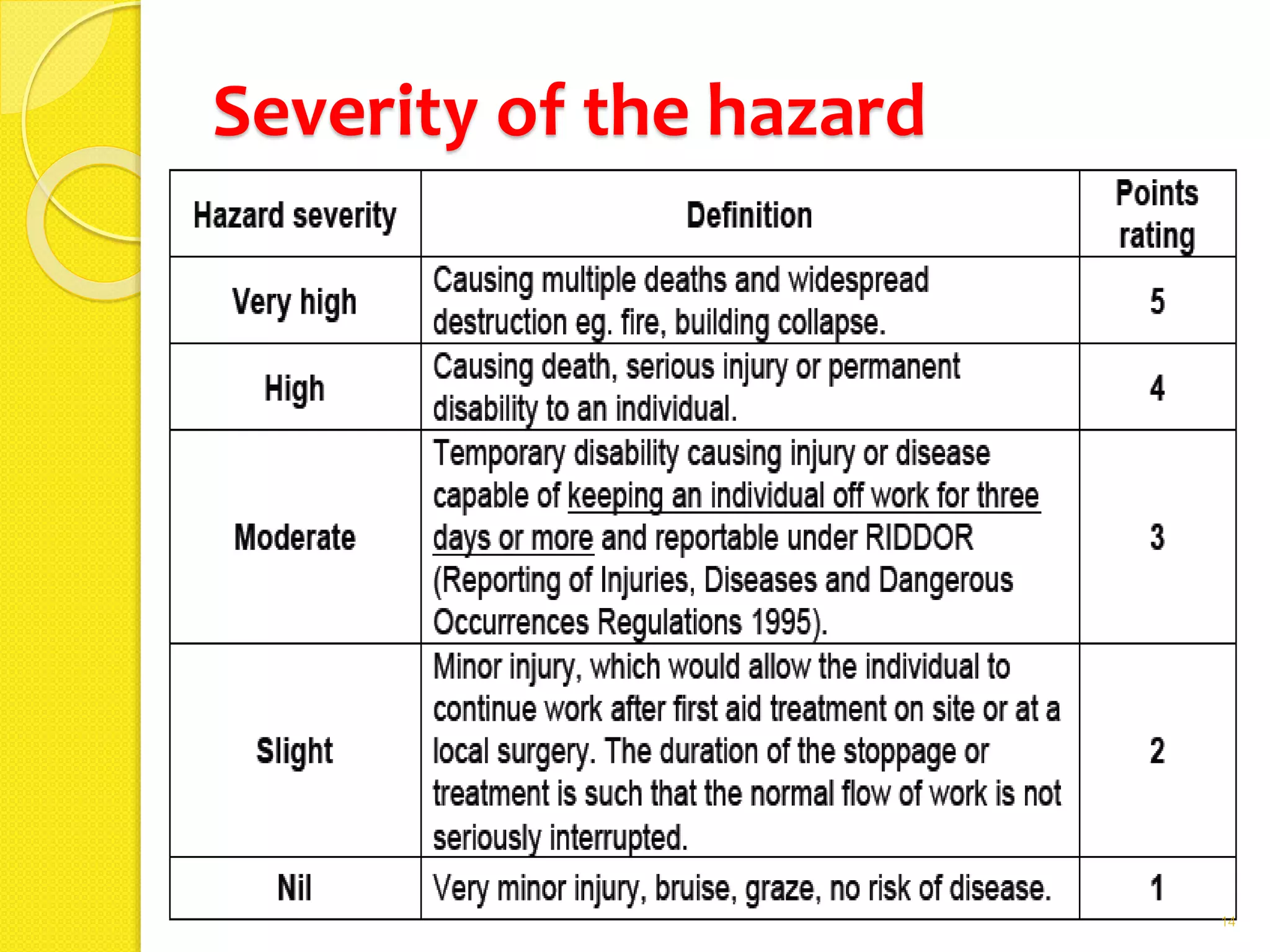

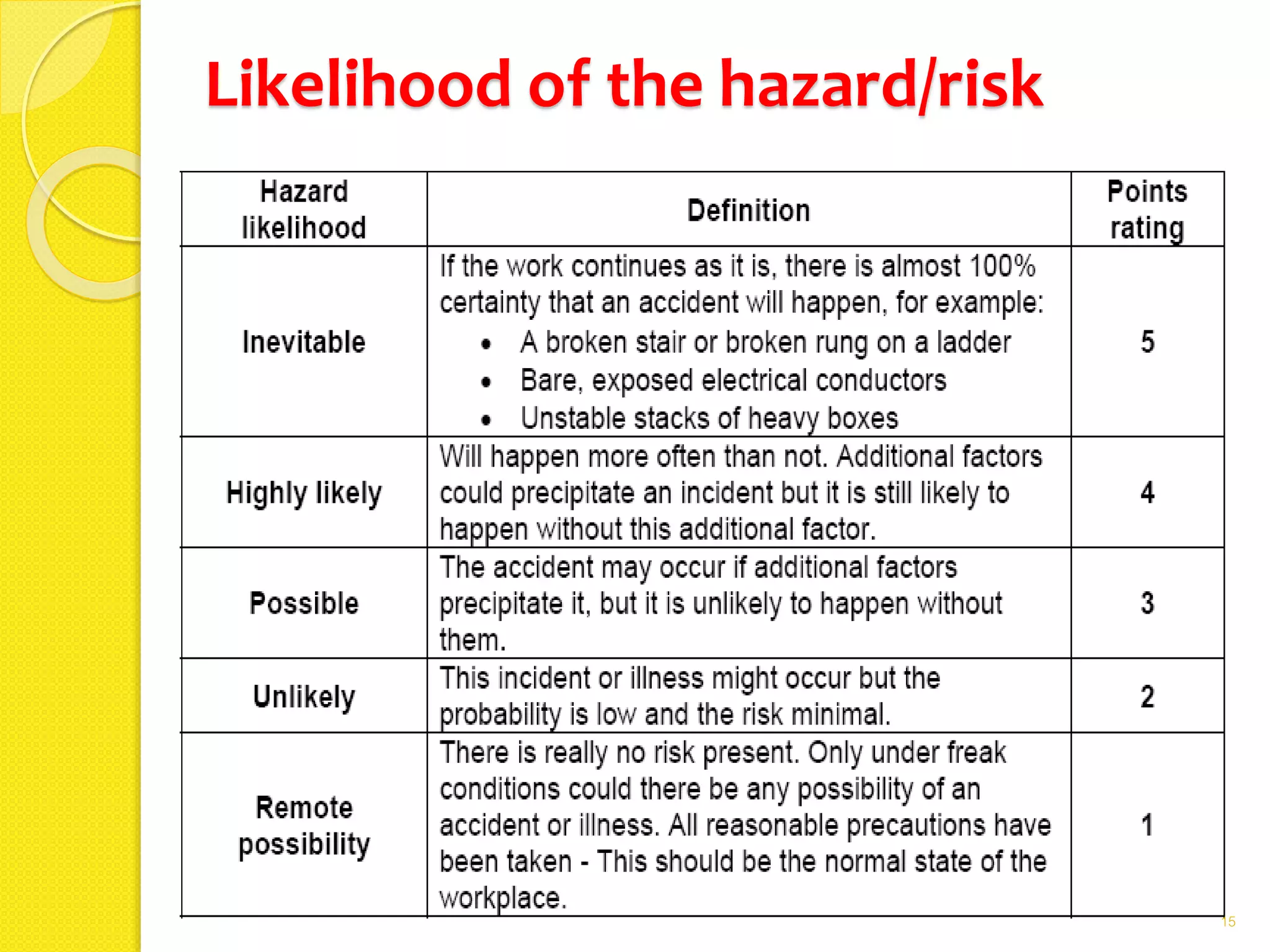

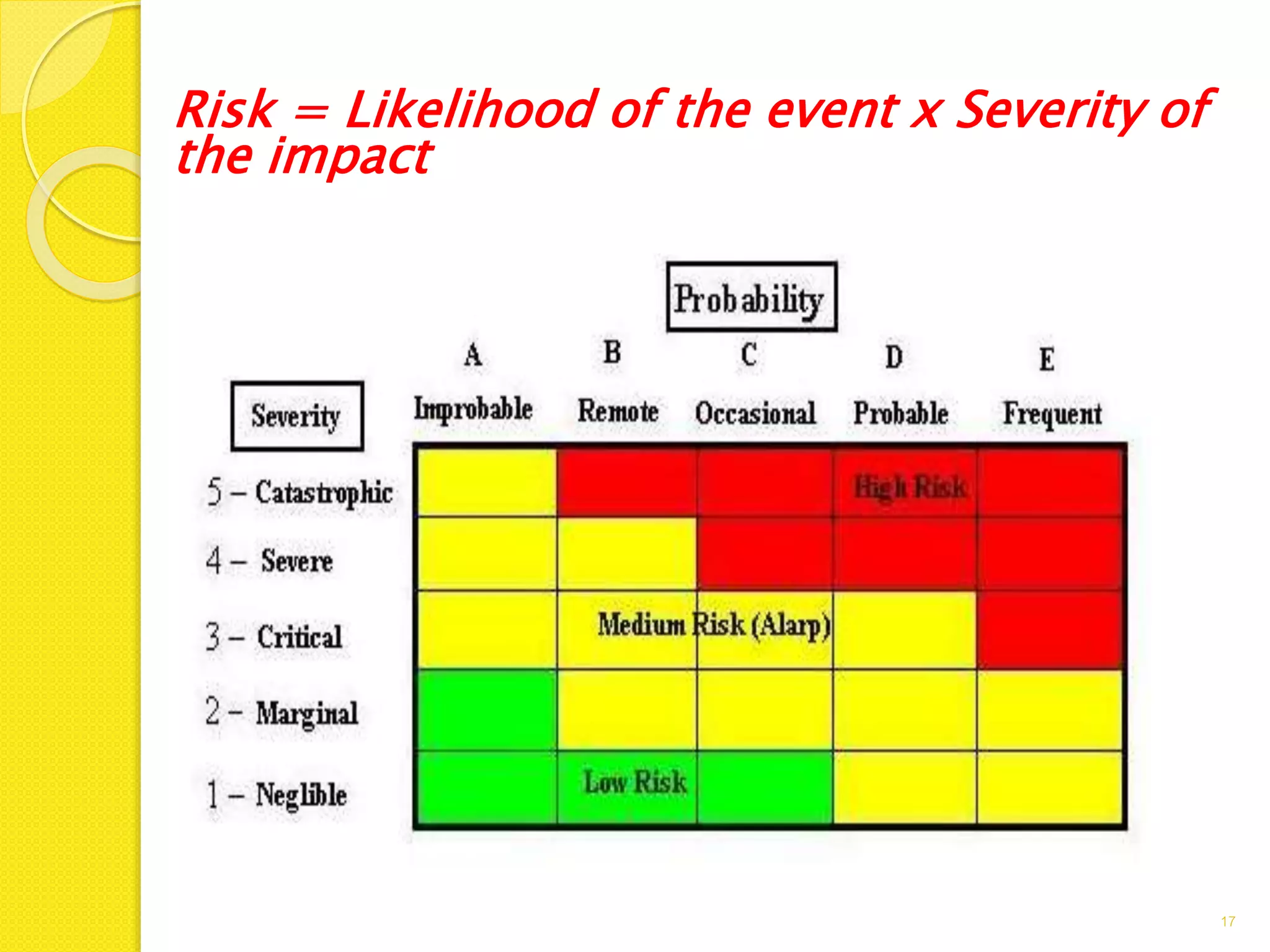

The document outlines the process of risk assessment, which involves identifying, quantifying, and managing risks associated with chemical and physical agents in the workplace. It details seven steps for conducting a risk assessment, emphasizing the importance of creating awareness, identifying at-risk individuals, and implementing control measures to prevent harm. Regular reviews and updates to the assessment are necessary to ensure ongoing safety and effectiveness.