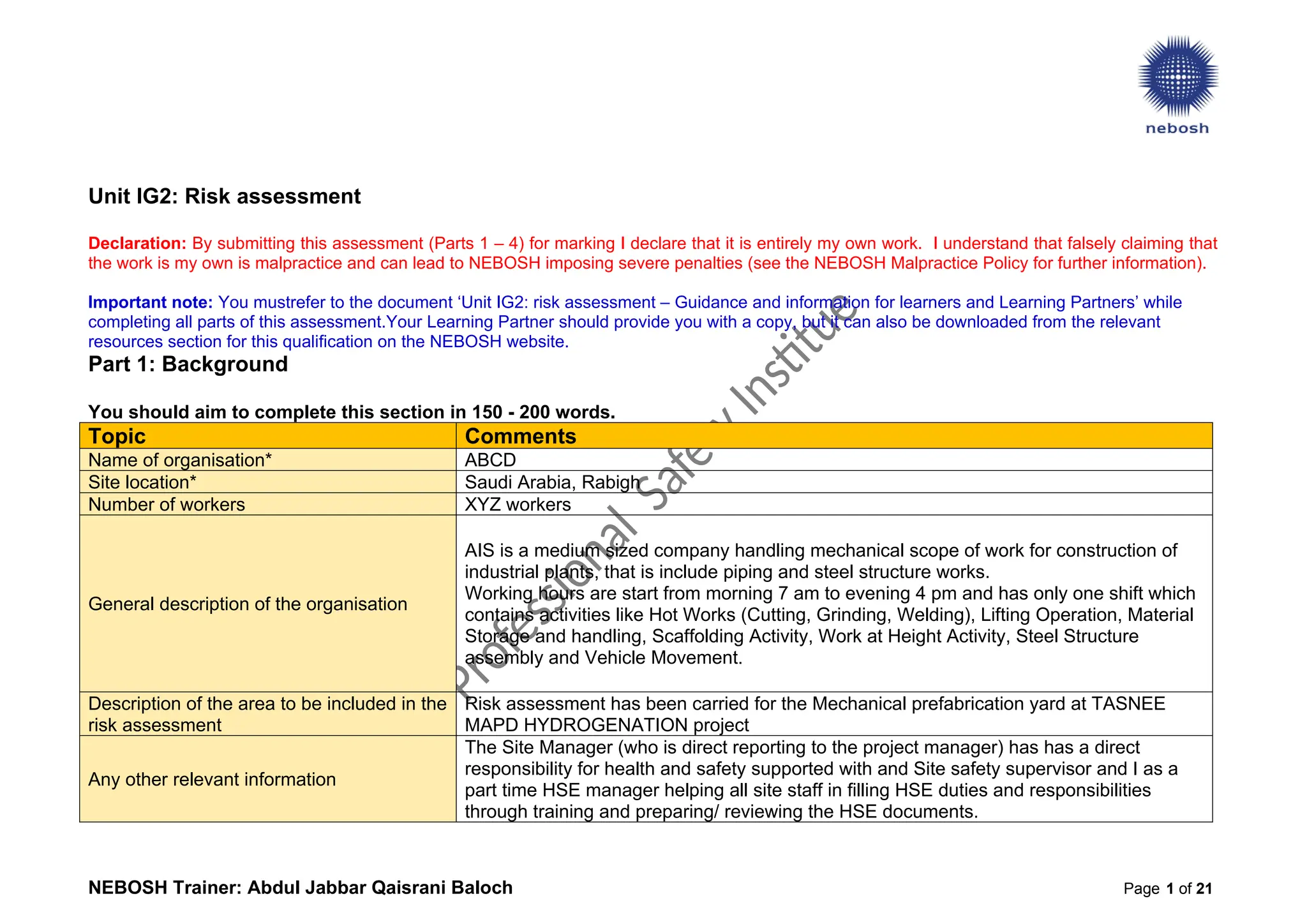

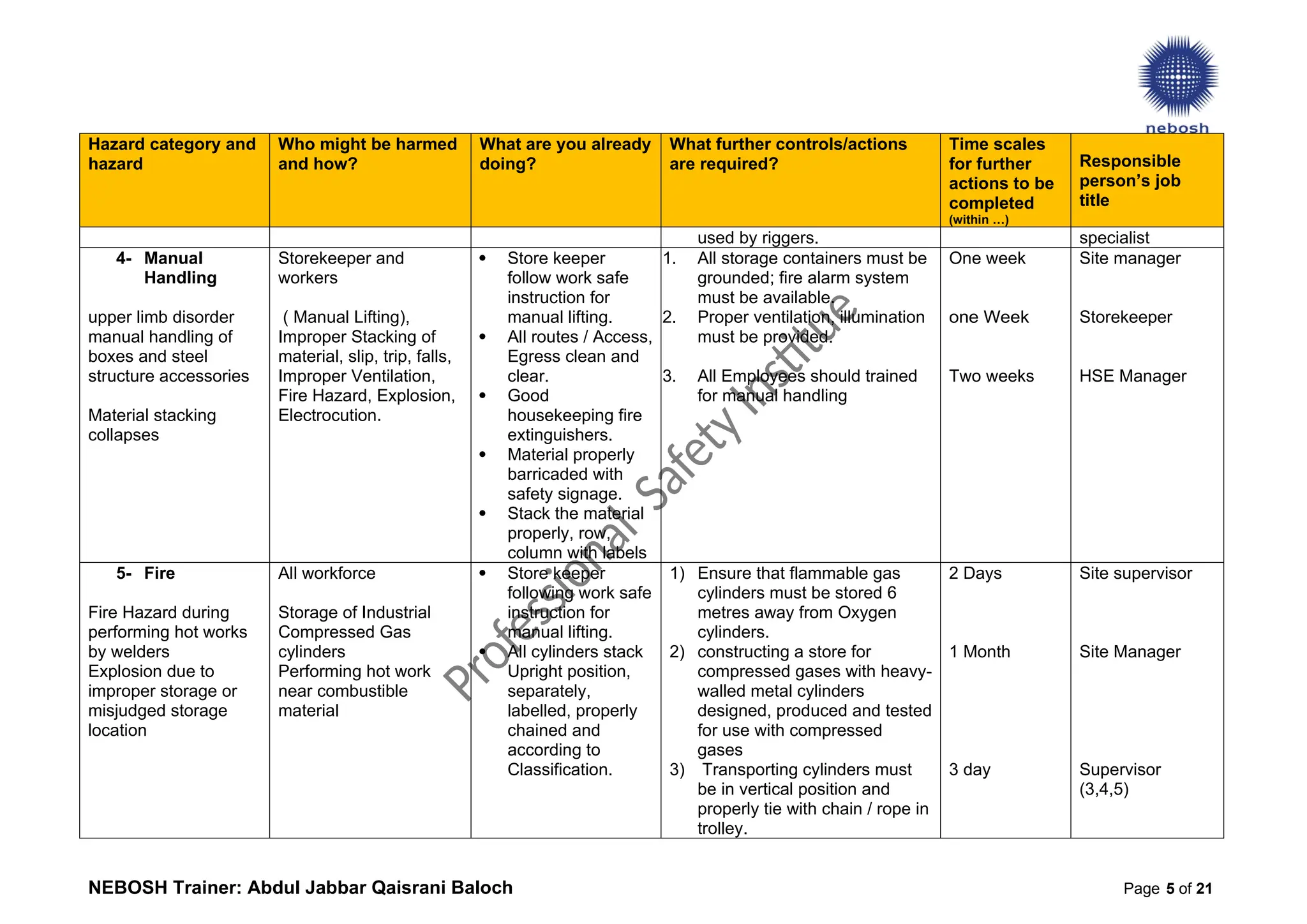

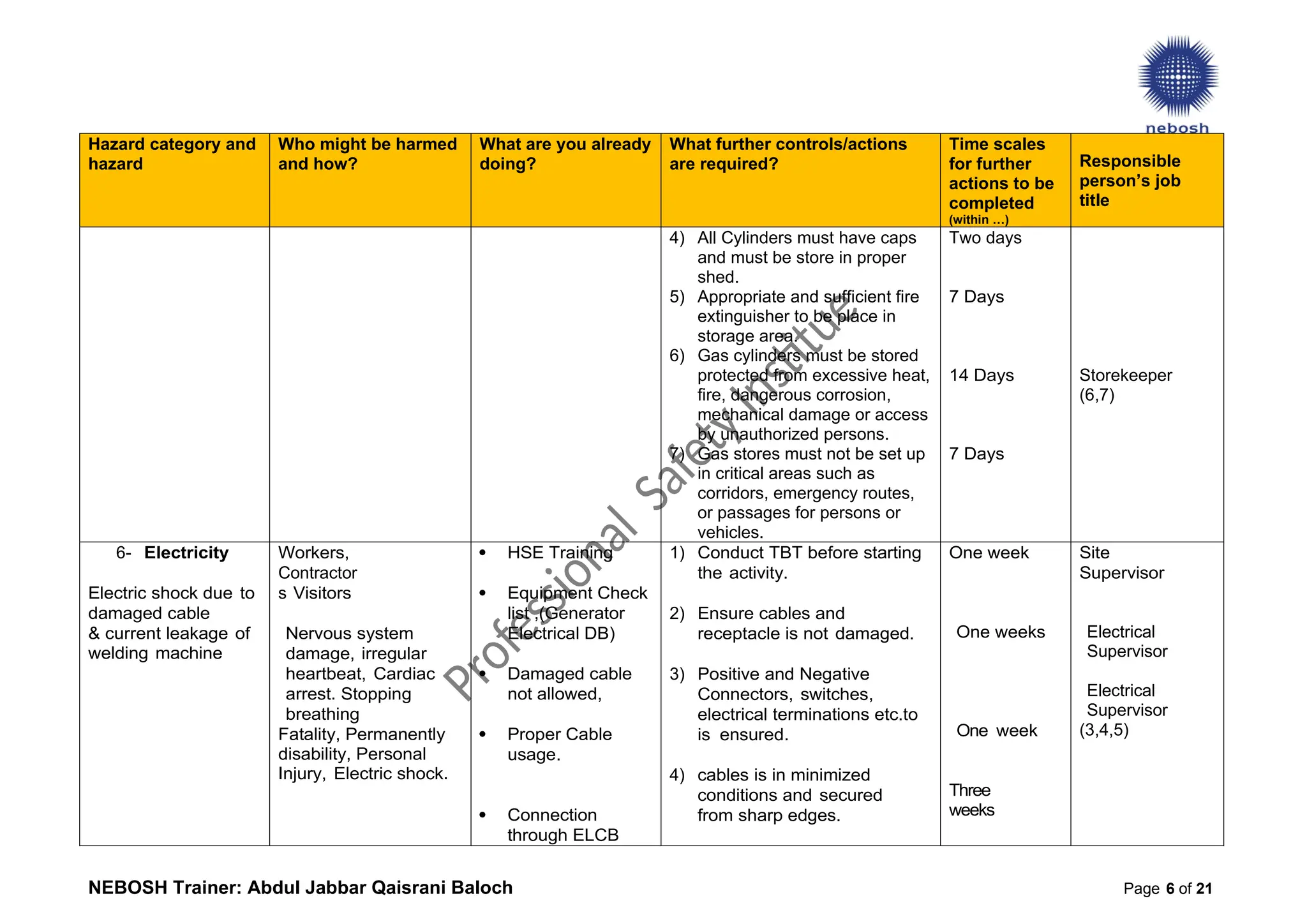

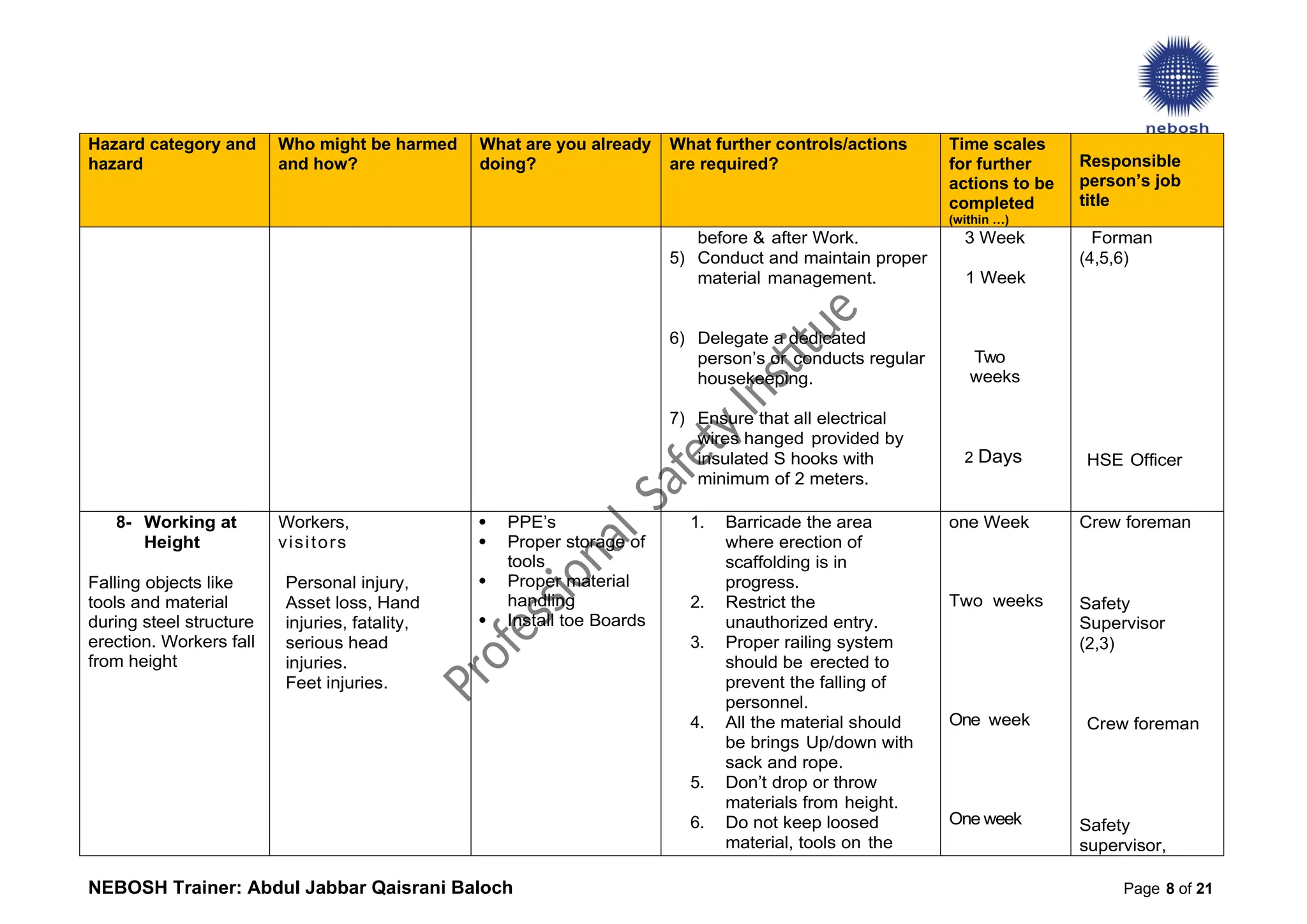

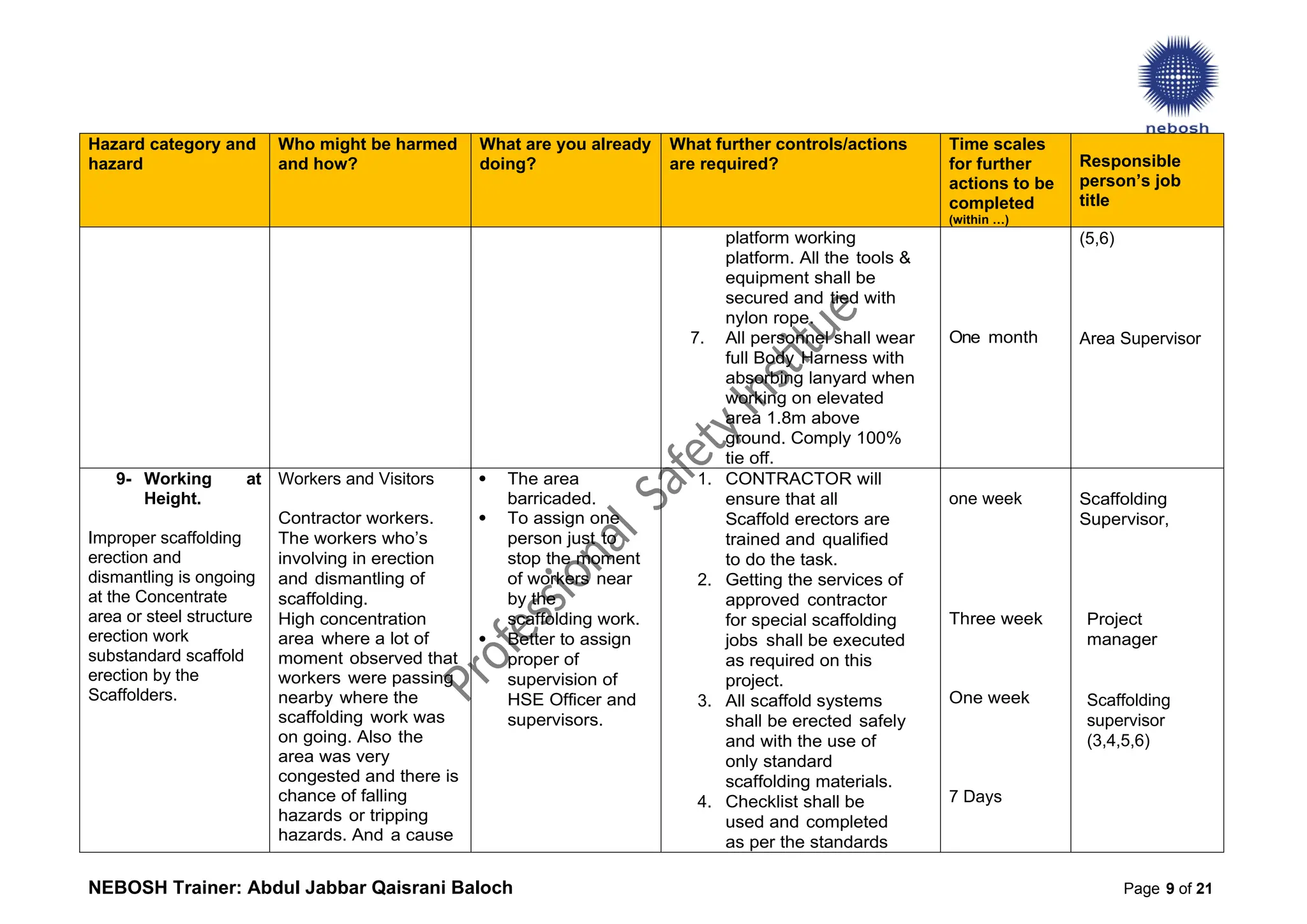

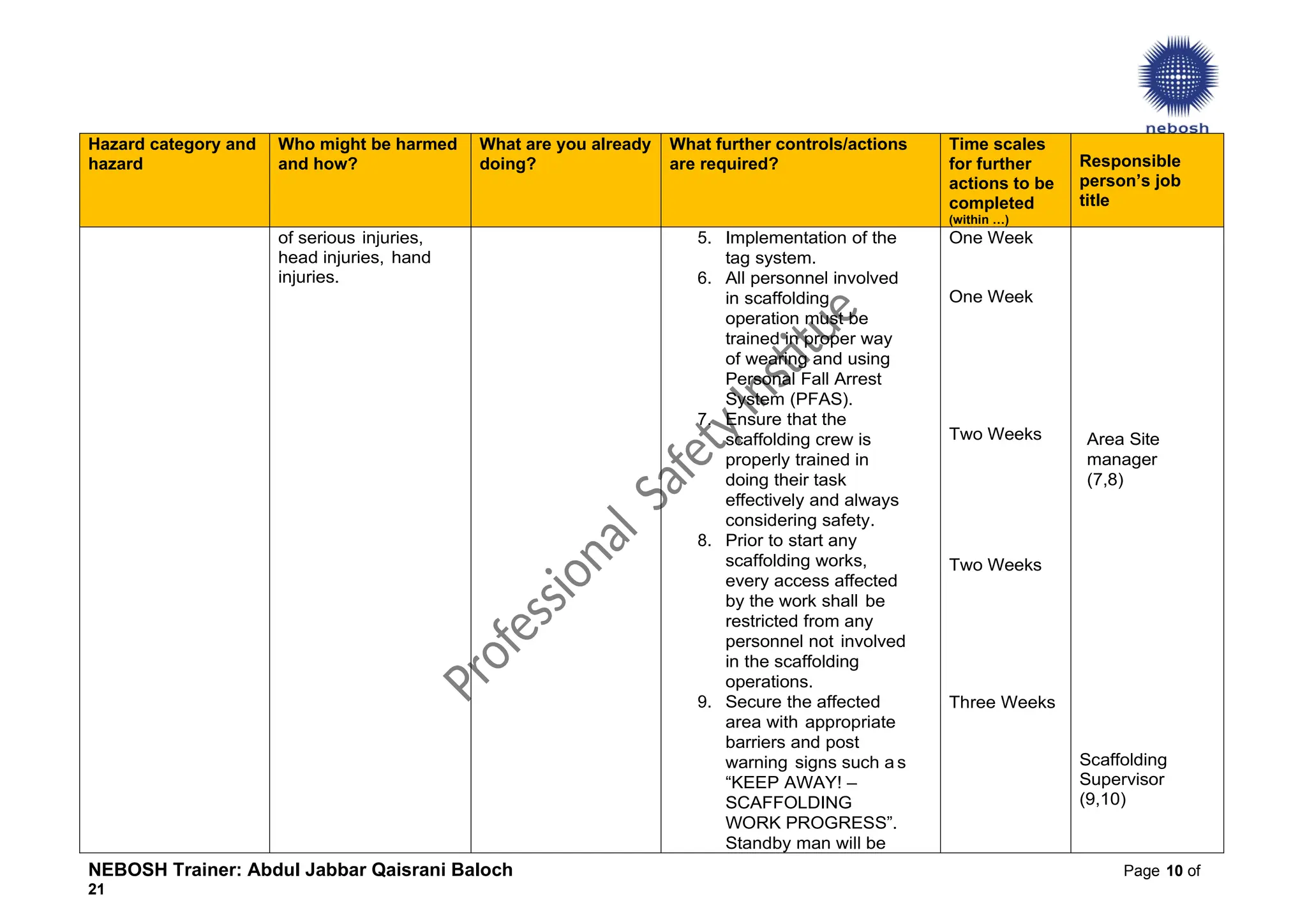

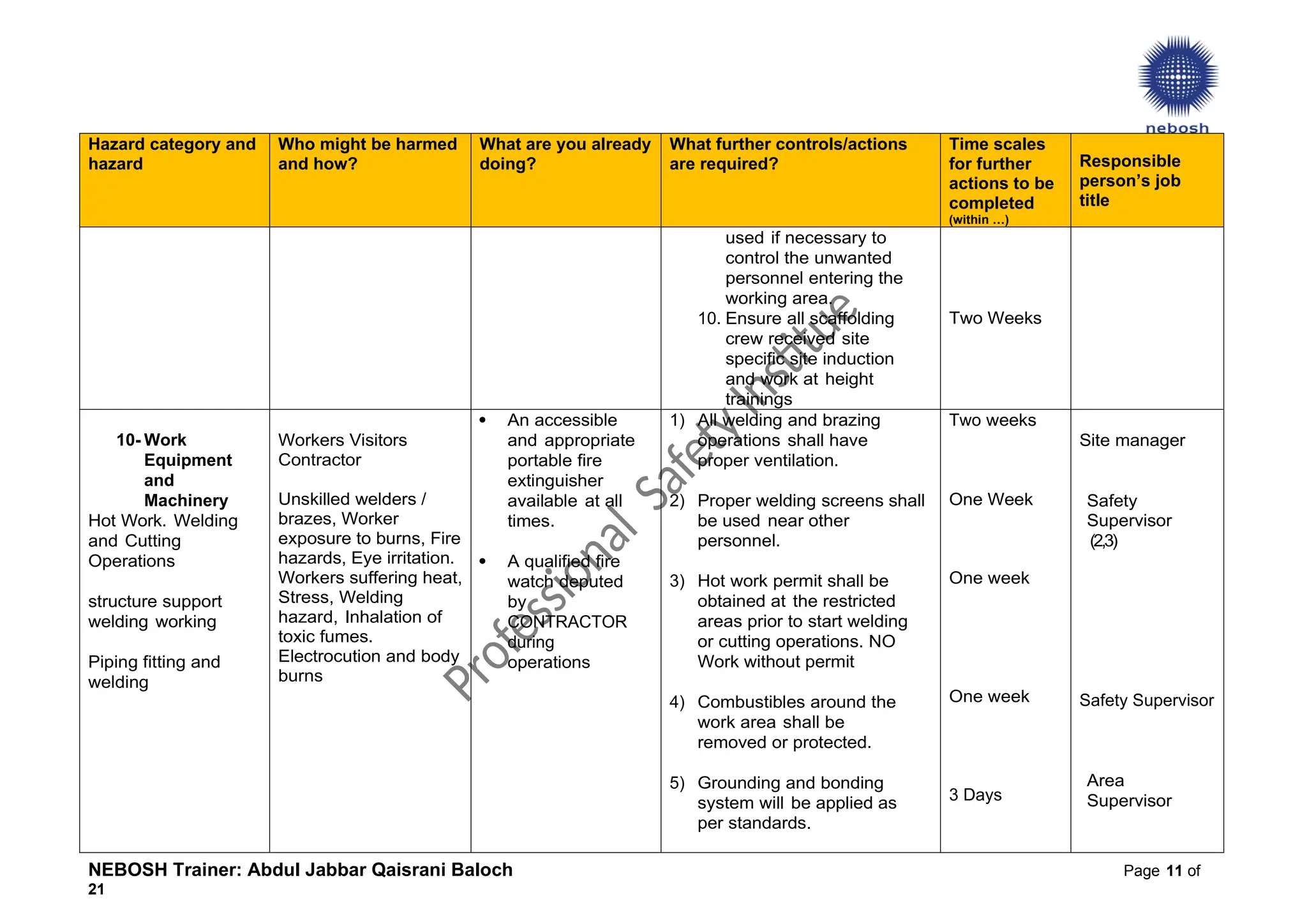

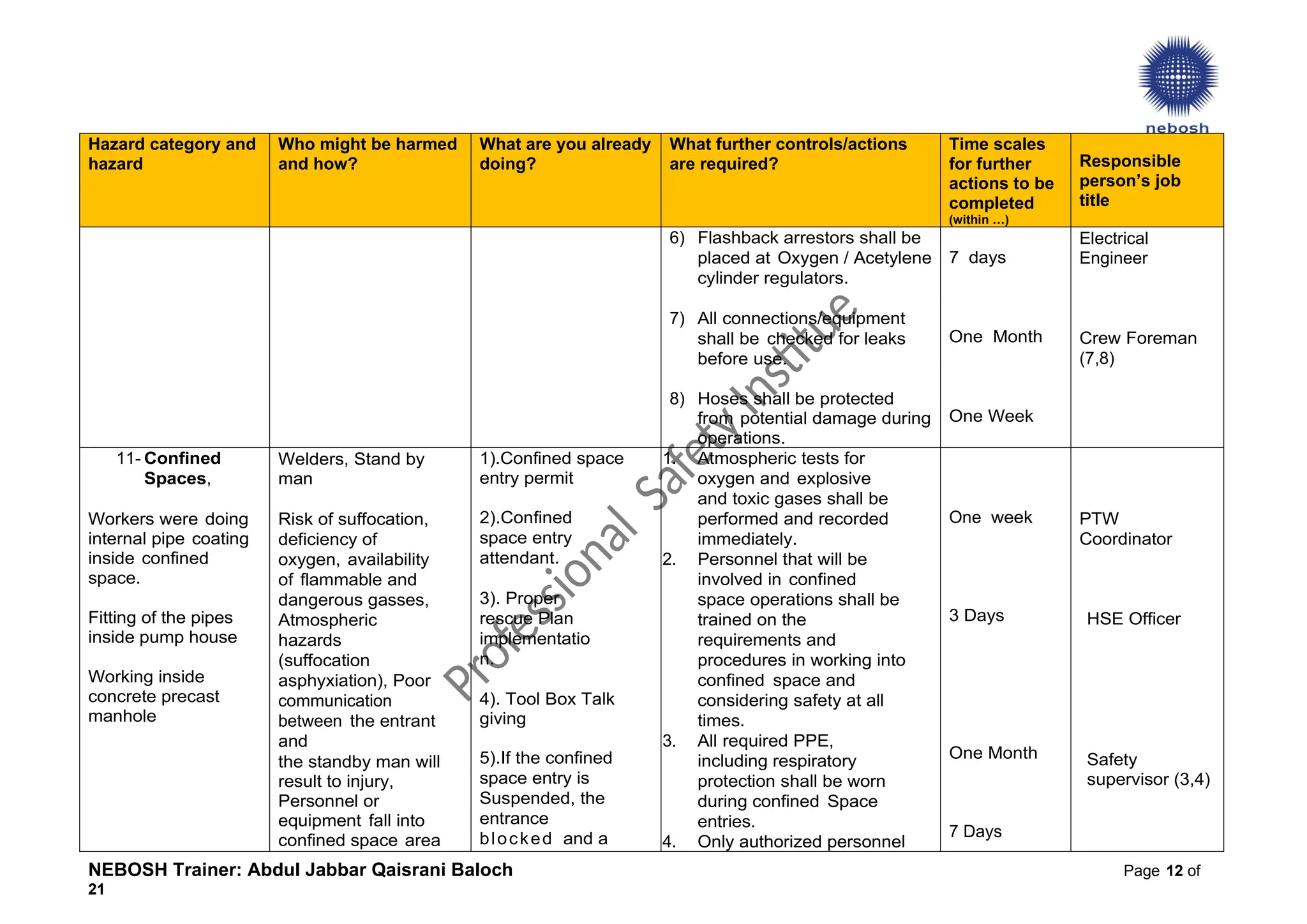

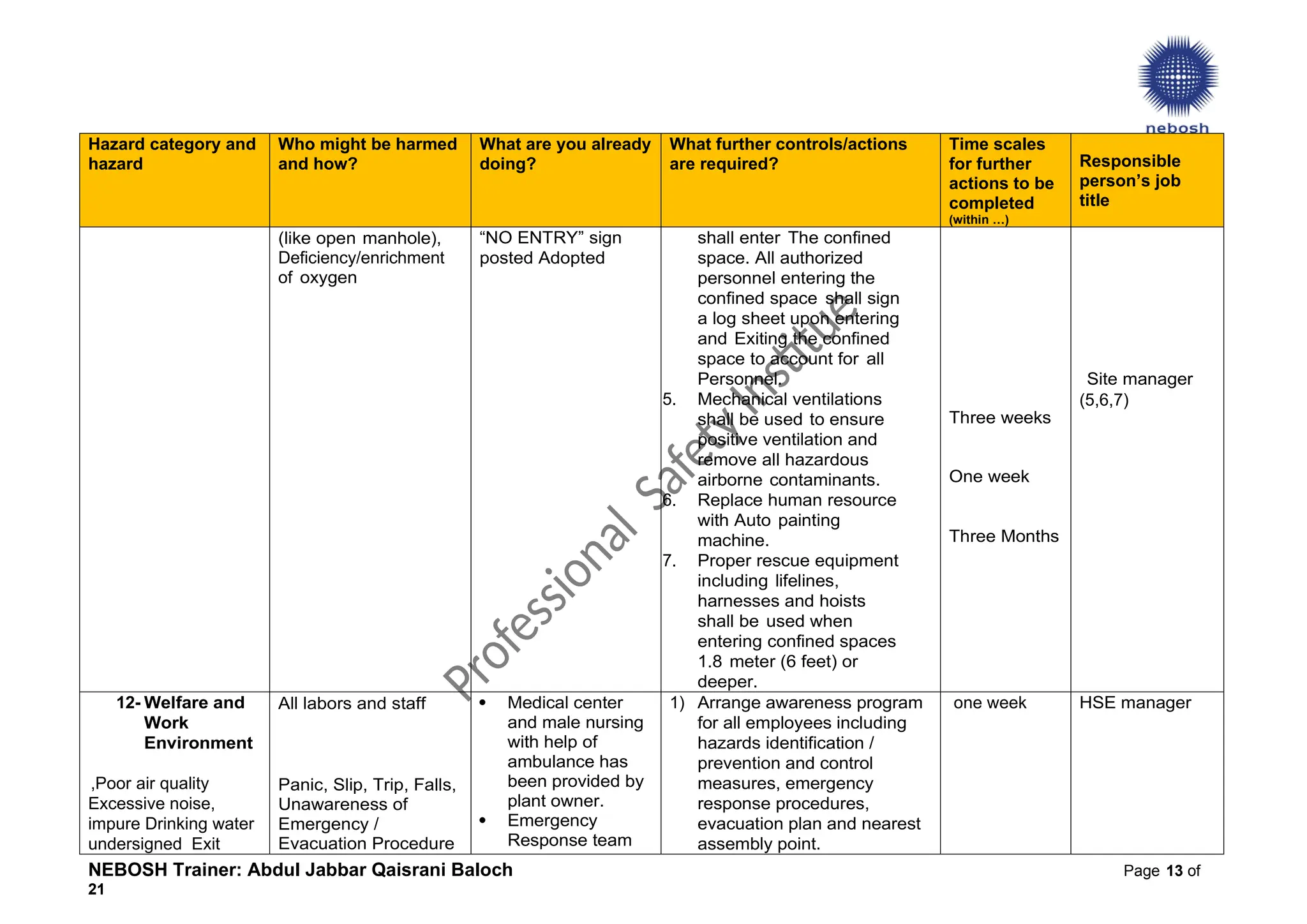

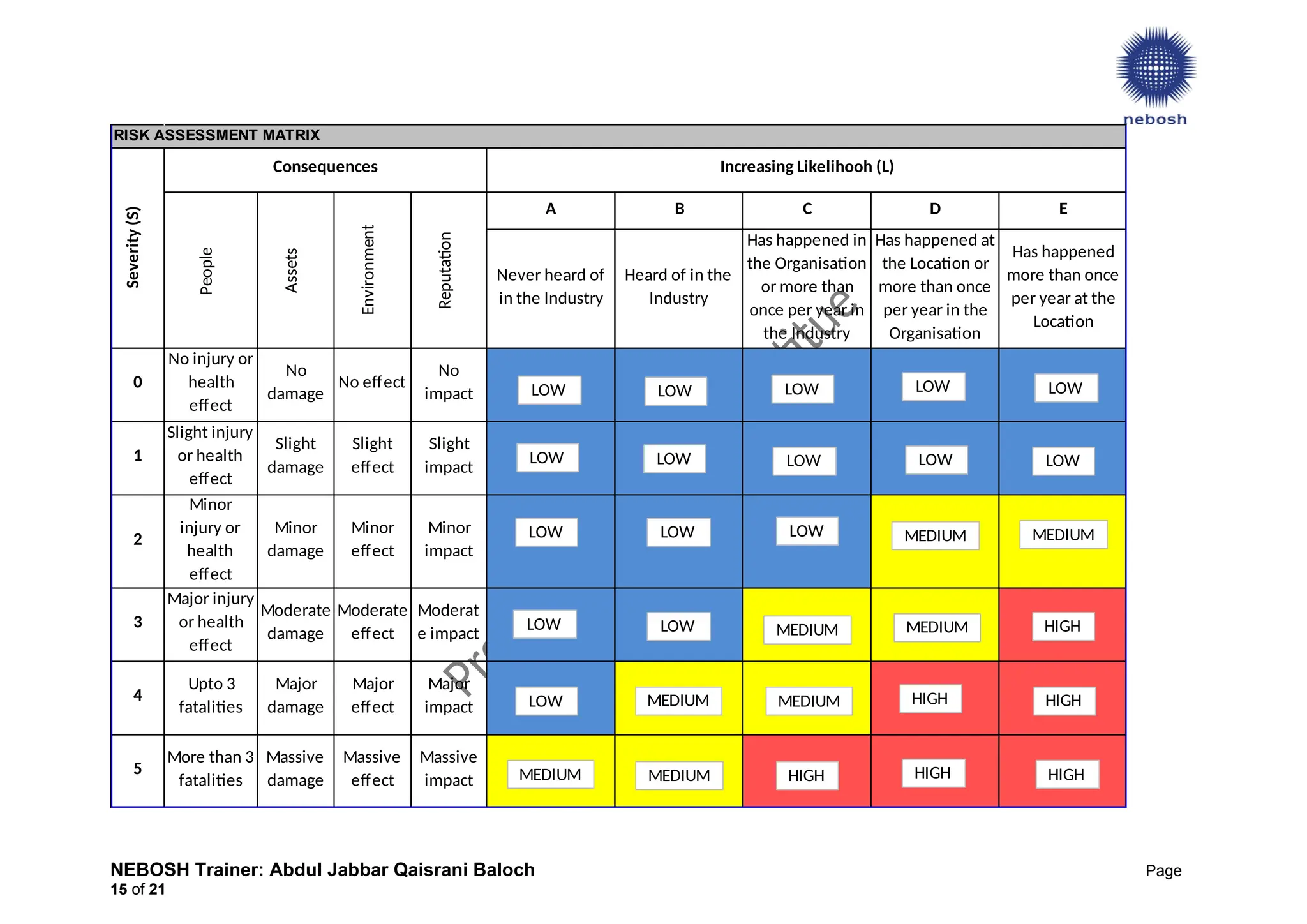

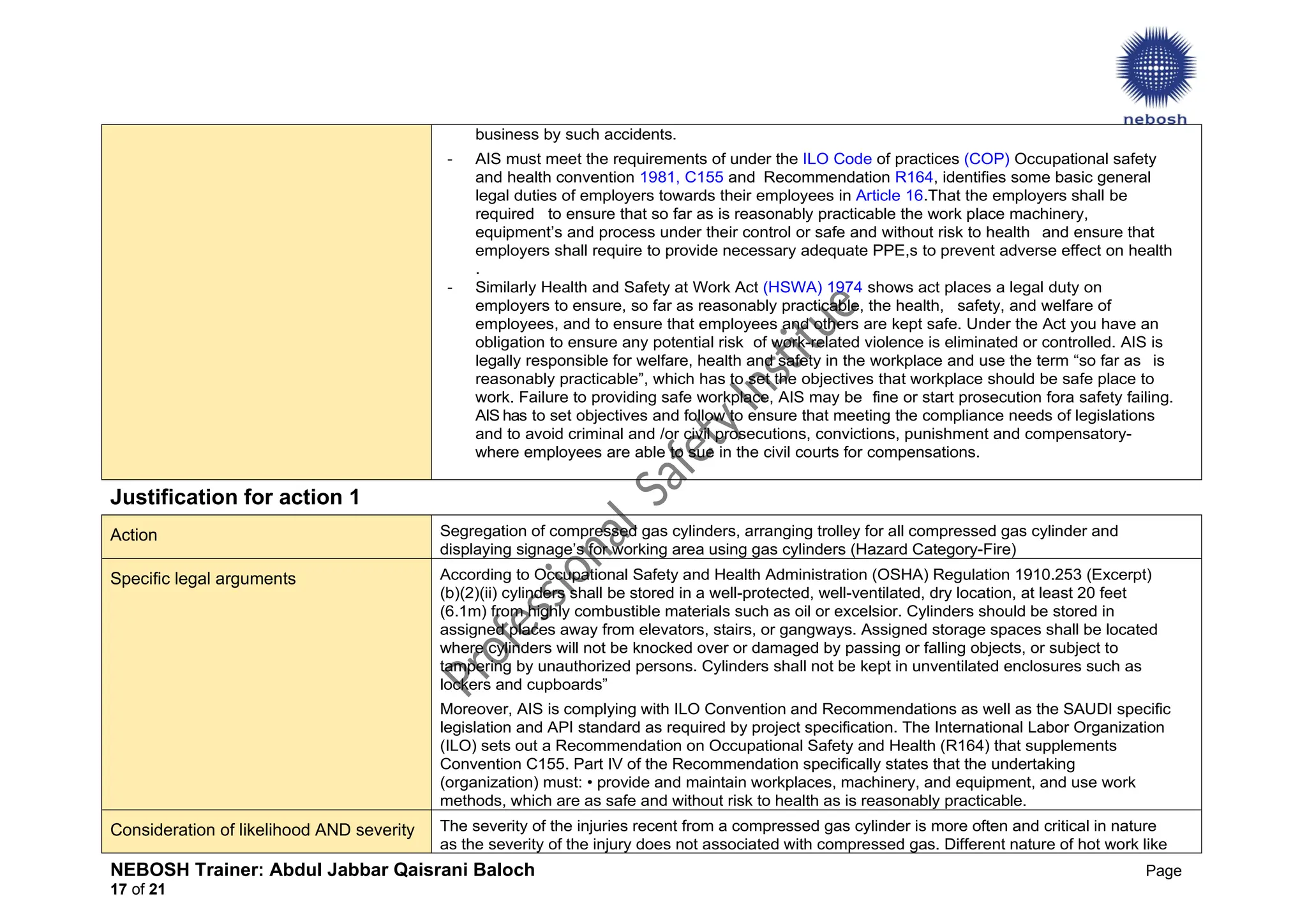

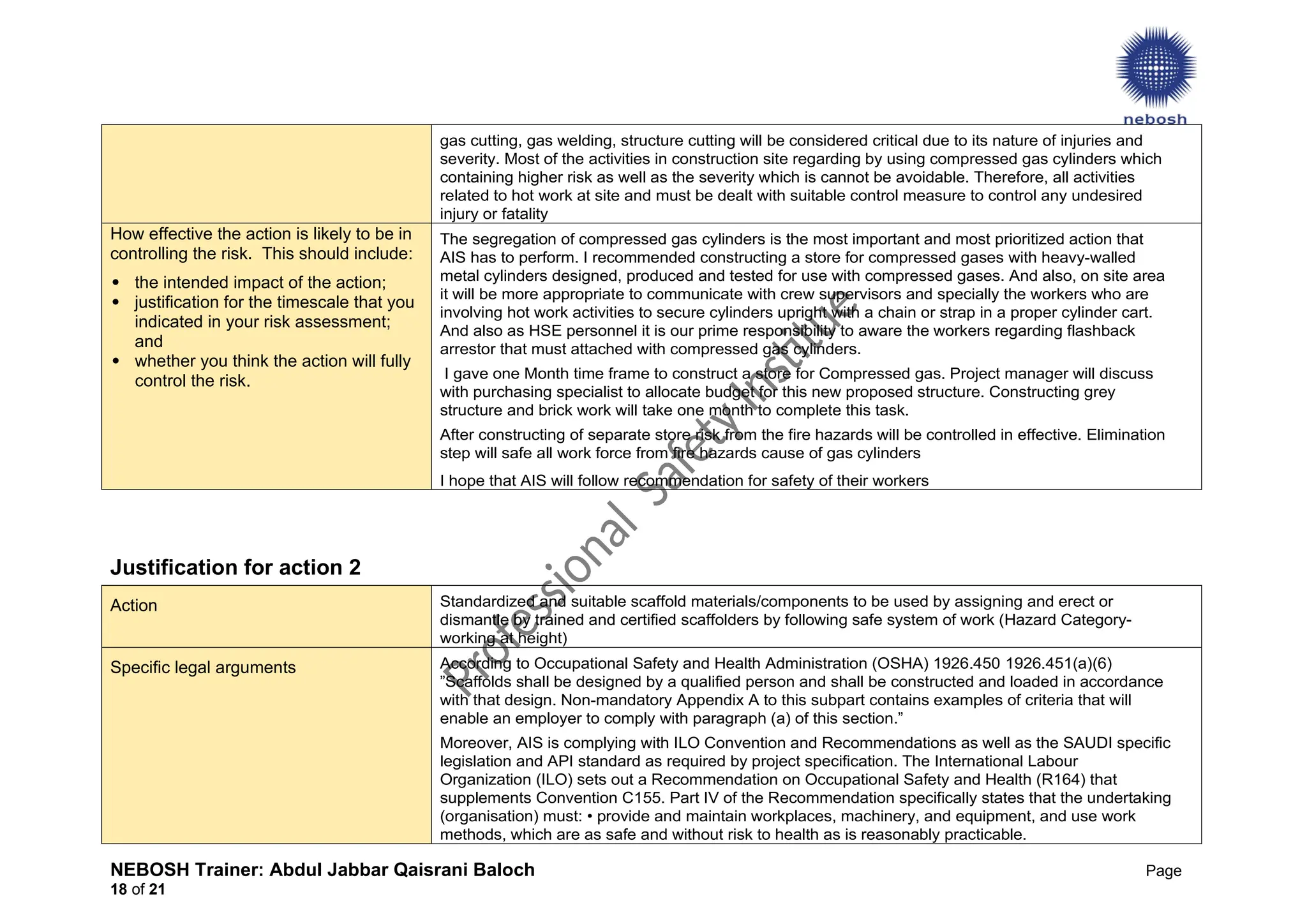

The document is a risk assessment declaration required for a NEBOSH qualification, outlining the author's commitment to originality and adherence to health and safety guidelines. It details the organization involved, the risk assessment scope at the mechanical prefabrication yard in Saudi Arabia, and specific hazards identified with corresponding existing and required controls. Additionally, it includes a semi-quantitative risk assessment approach, highlighting communication with relevant parties to ensure safety measures are adequately implemented.