This document summarizes a seminar presentation on photovoltaic cells. The presentation covered:

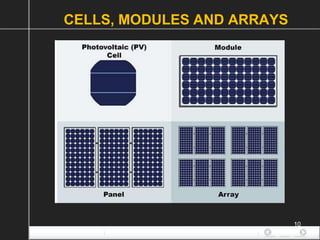

- An introduction to photovoltaics, which are semiconductor devices that convert sunlight to direct current electricity. PV cells are arranged into modules and arrays.

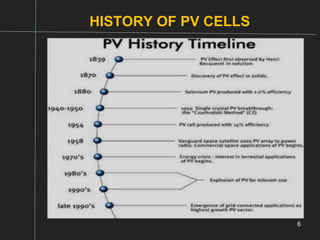

- A brief history of PV cells including early uses to power satellites and navigational aids in the 1950s-1960s and later consumer electronics.

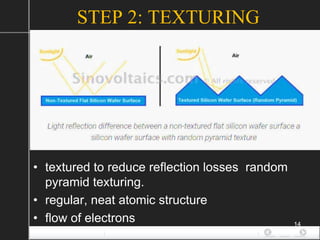

- The 9-step production process for silicon wafer-based PV cells including pre-treatment, texturing, diffusion, anti-reflective coating, contact printing, and final testing and sorting.