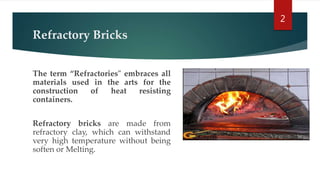

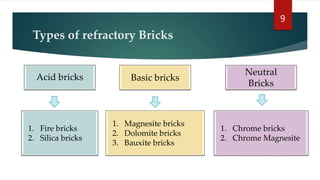

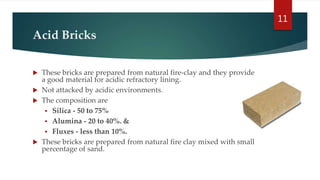

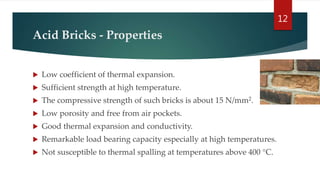

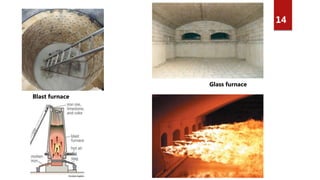

Refractory bricks are made from refractory clay and can withstand very high temperatures without softening or melting. They contain materials like silica, alumina, and magnesia that provide heat resistance. Refractory bricks are classified as acid bricks, basic bricks, or neutral bricks depending on their chemical composition and intended application. Acid bricks are used in acidic environments like blast furnaces. Basic bricks contain a high percentage of magnesia and are used where resistance to basic slags is required. Neutral bricks are chemically inert and used to separate acid and basic linings in furnaces.