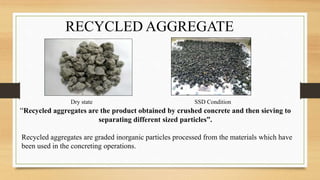

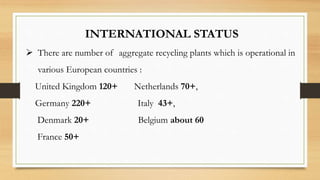

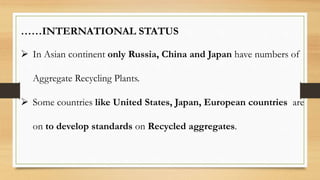

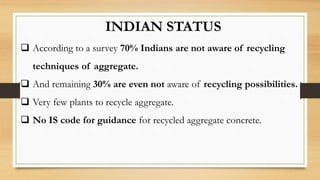

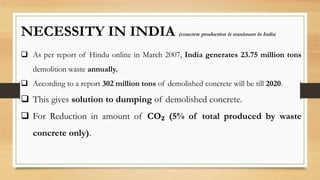

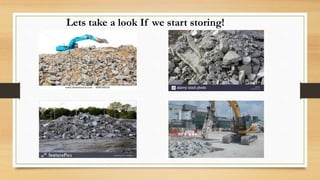

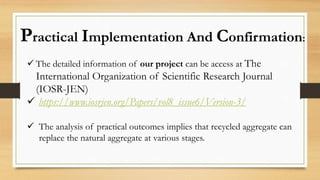

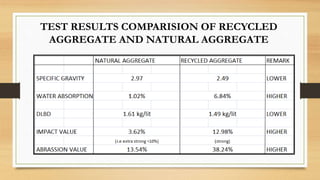

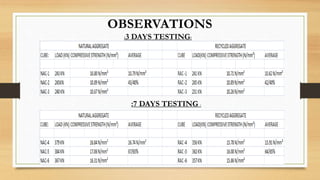

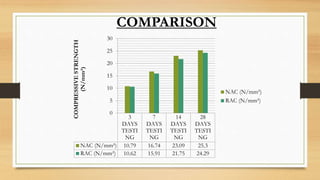

The document discusses the importance and status of recycled aggregate concrete (RAC), highlighting its historical development and current usage in India and internationally. It emphasizes the need for recycling techniques due to the significant amount of demolition waste generated and the environmental benefits associated with RAC. Recommendations include developing standards for recycled aggregates and increasing public awareness about recycling methods.