Embed presentation

Downloaded 58 times

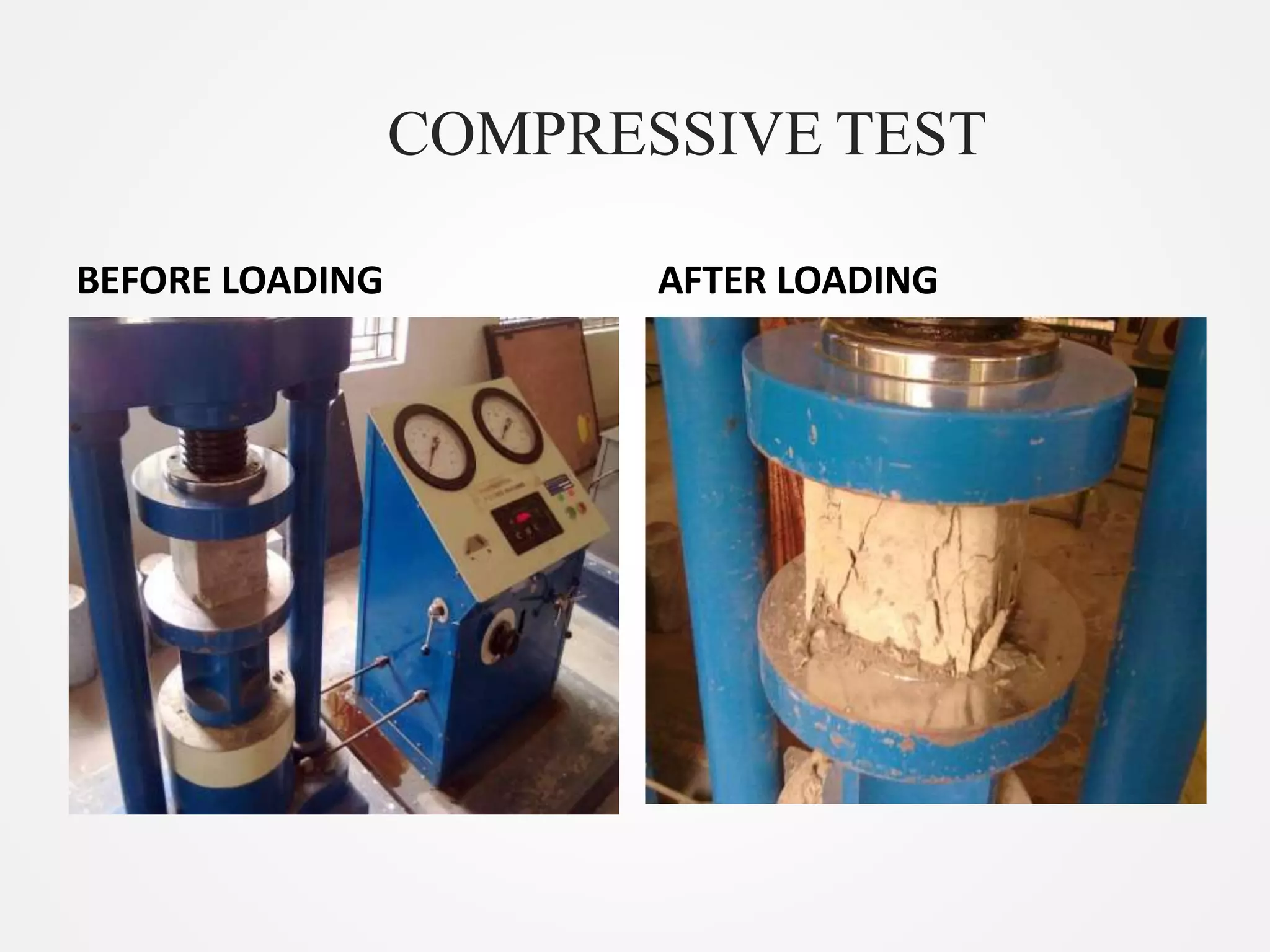

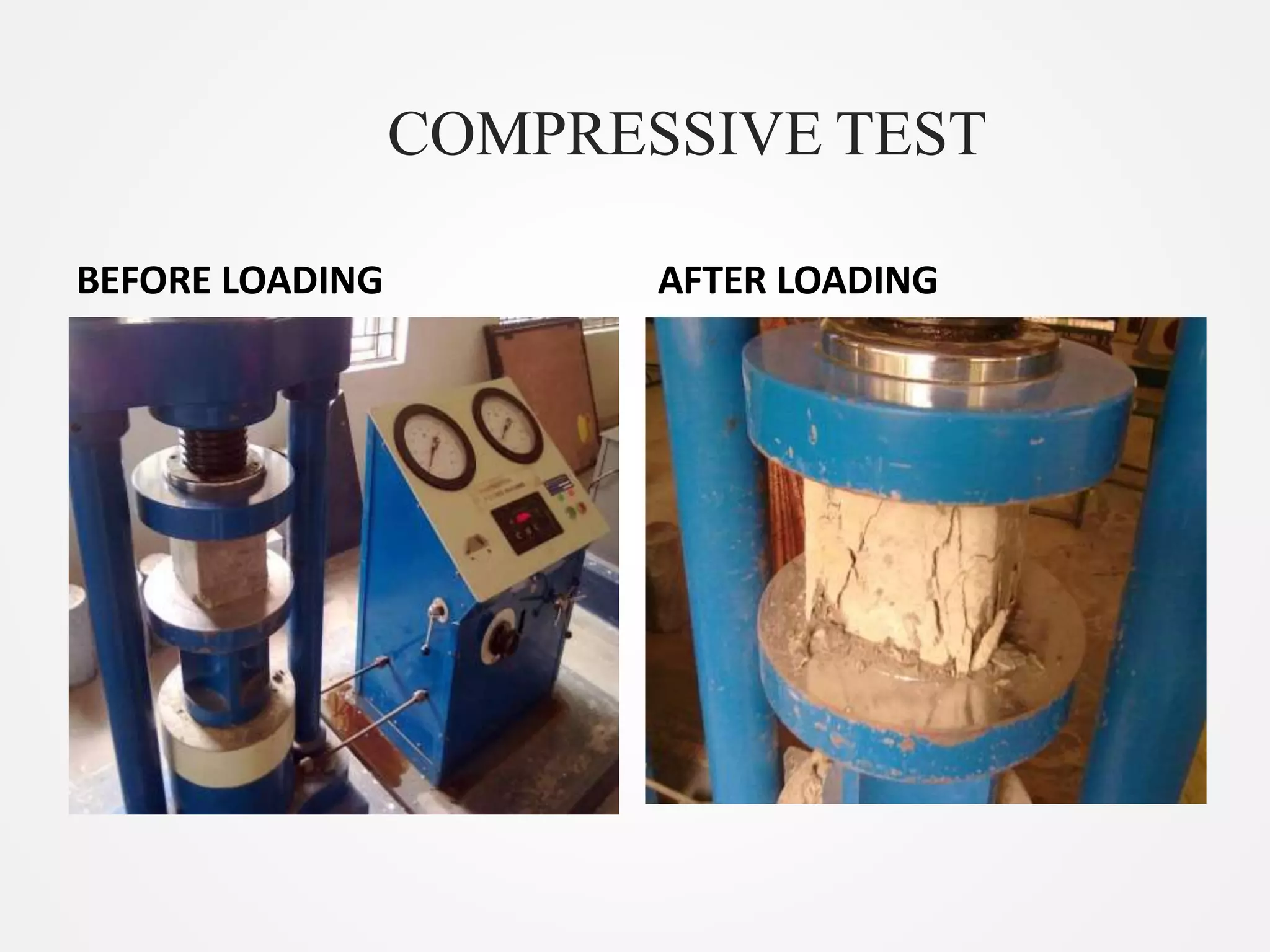

This document describes procedures for testing the compressive strength of concrete cubes. Compressive strength is the maximum load a material can withstand before crushing. The test involves applying an increasing compressive load to molded concrete cubes until failure. Cubes are cured for 7 or 28 days before testing. The compressive strength is calculated by dividing the maximum load by the cross-sectional area of the cube.