Embed presentation

Downloaded 13 times

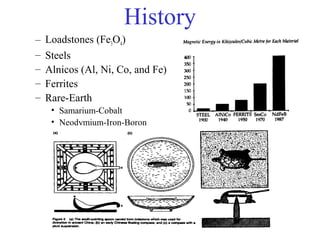

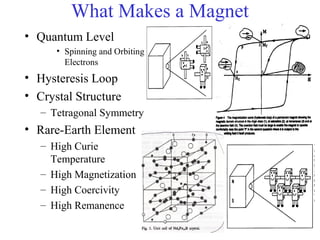

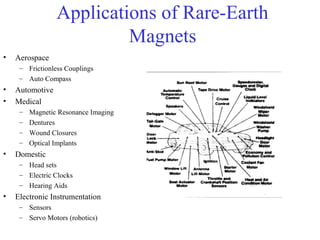

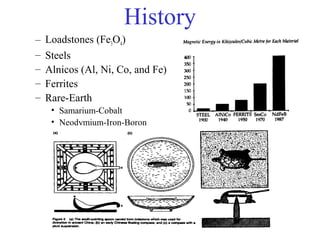

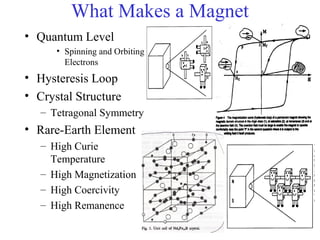

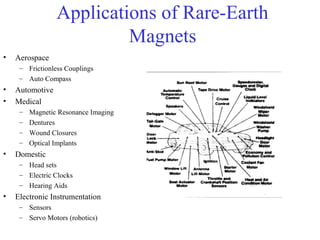

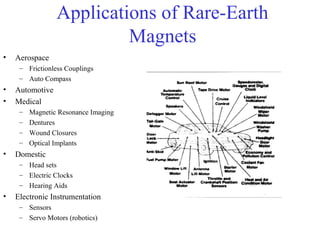

Rare earth magnets have evolved from loadstones and steels to modern alloys like samarium-cobalt and neodymium-iron-boron. They are made through processes like compressing alloy flakes or sintering powder under high heat. Rare earth elements make strong magnets through quantum effects that align electron spins into a magnetized crystal structure with high magnetic properties. These magnets find applications in technologies like MRI machines, sensors, motors, and audio devices.