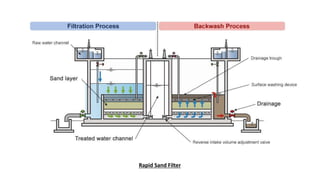

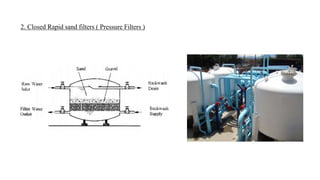

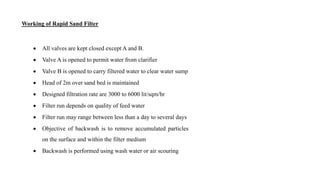

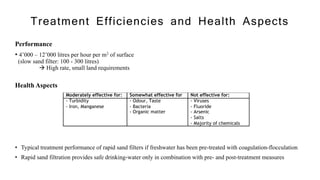

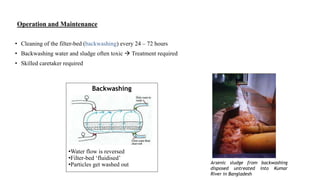

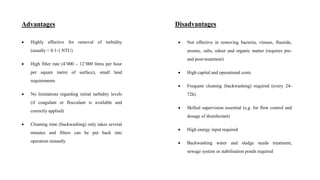

The document discusses the rapid sand filtration technique used for treating drinking water, detailing its operation, types, and essential features. It highlights the advantages and disadvantages, such as effective turbidity removal but limitations in reducing contaminants like bacteria and salts, necessitating pre- and post-treatment measures. Additionally, it emphasizes the need for skilled supervision and proper maintenance to manage the complex processes involved.