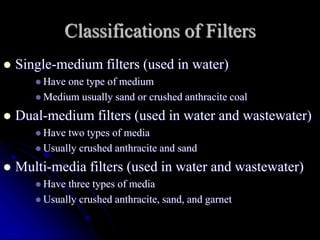

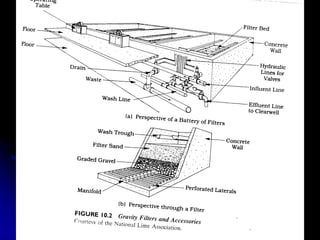

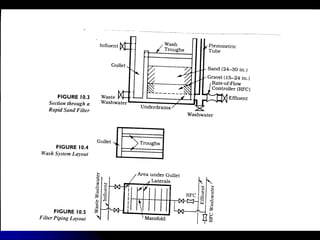

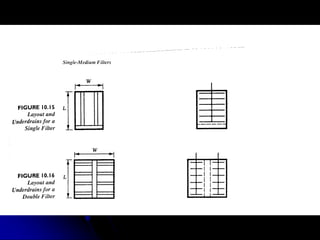

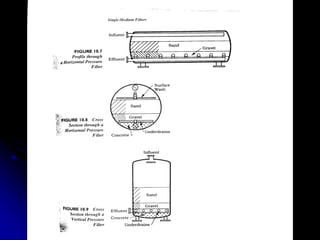

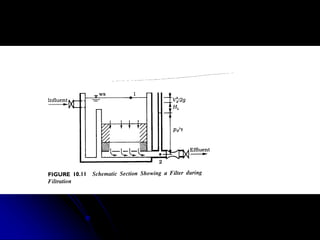

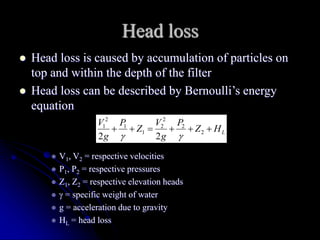

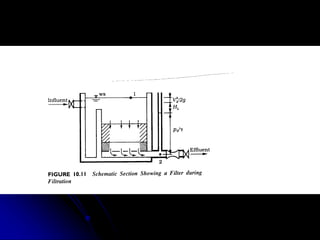

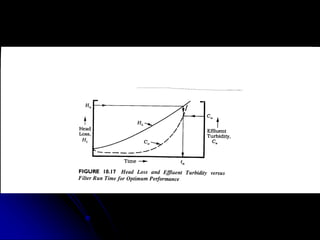

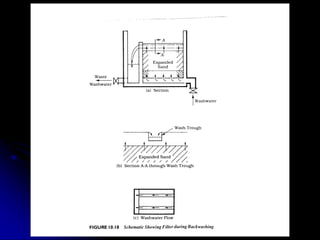

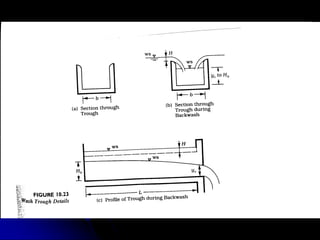

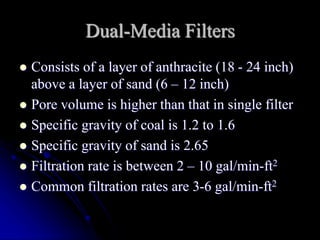

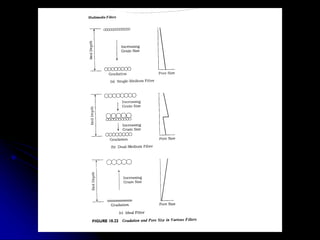

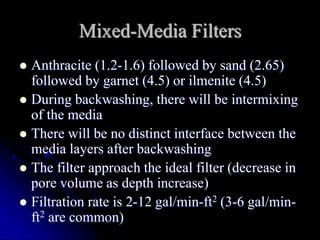

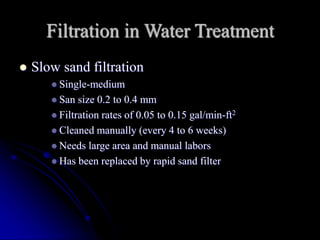

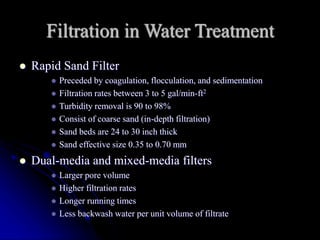

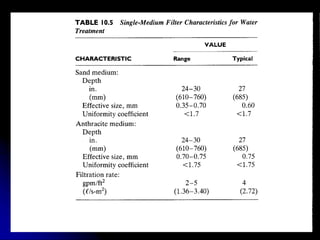

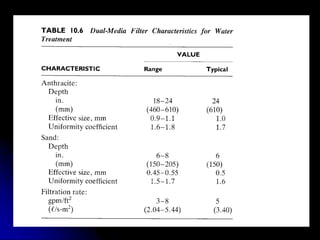

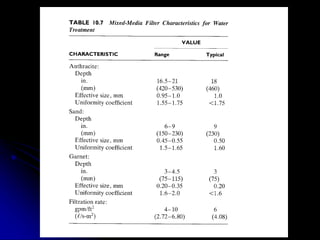

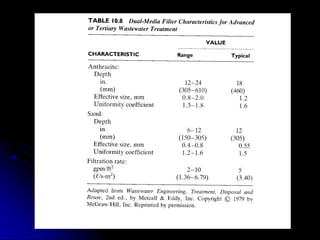

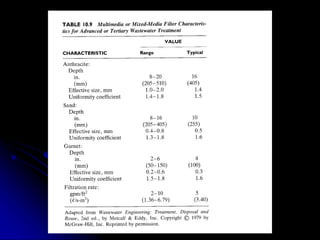

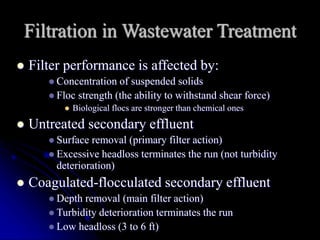

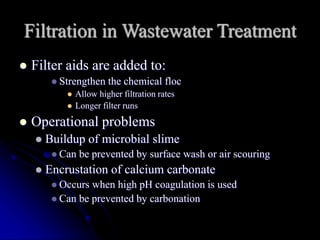

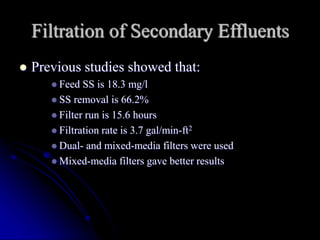

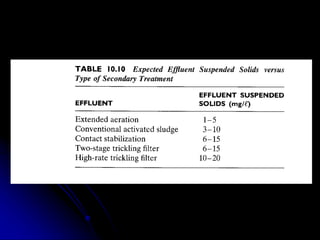

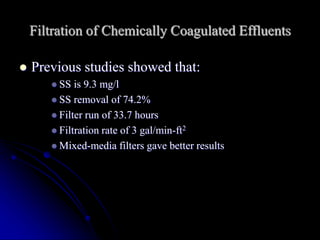

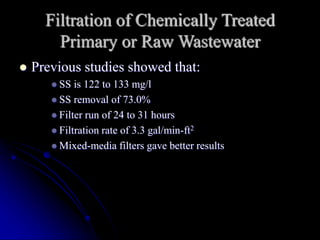

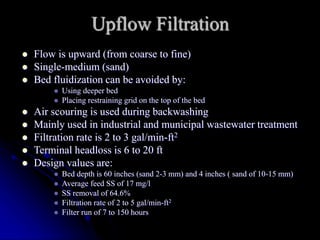

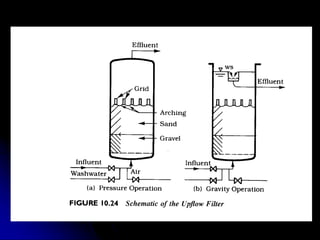

This document discusses filtration, which uses a porous medium to remove fine suspended solids from liquid. Filtration is used in water treatment and wastewater treatment. It describes different types of filters including single-medium, dual-medium, and mixed-media filters. It also discusses the filtration process, mechanisms of particle removal, head loss, filtration rates, and operational considerations like backwashing. Filtration is effective at removing suspended solids in water and wastewater treatment applications.