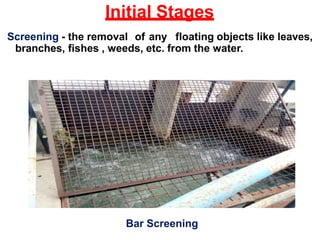

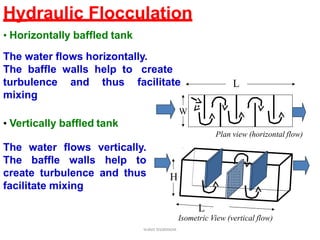

This document summarizes the key stages in a typical water treatment process, including initial collection and screening of raw water, aeration, sedimentation, coagulation and flocculation to remove suspended solids, filtration to remove microorganisms and colloids, and disinfection through chlorination to kill bacteria. It describes the purpose and mechanisms of processes like coagulation, flocculation, sedimentation, and filtration. Different filter types are also outlined, including slow sand filters, rapid sand filters, and pressure filters.