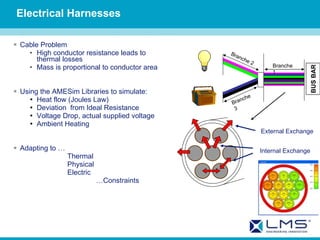

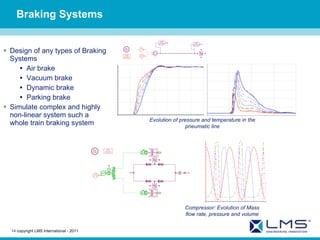

The document discusses LMS Simulation Division's multi-domain system simulation solutions for the railway and train industry. It addresses challenges in the industry related to growing demand for public transport and rising fuel costs. LMS offers simulation solutions to help deliver cost-efficient development, covering various train types and components like electric powertrains, braking systems, heating and air conditioning.