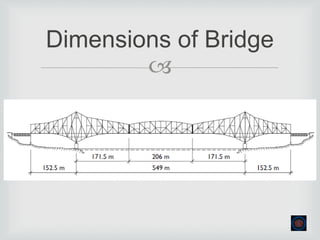

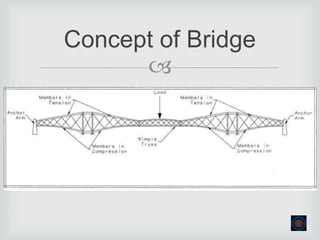

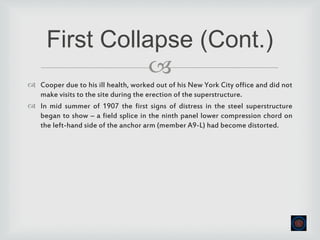

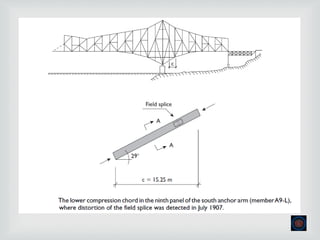

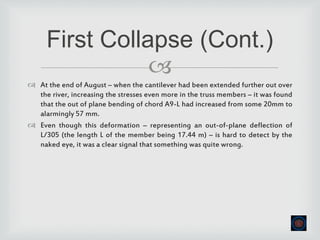

The Quebec Bridge, a cantilever bridge over the St. Lawrence River, faced two catastrophic collapses during its construction, first in 1907, killing 75 workers, and again in 1916 when deploying the final span, resulting in 13 fatalities. The bridge was eventually completed in 1917, becoming the longest cantilever bridge globally, after design improvements were made following the collapses. Investigations revealed engineering misjudgments, including underestimating the structure's self-weight and overestimating load capacity, leading to strengthened design protocols in bridge engineering.