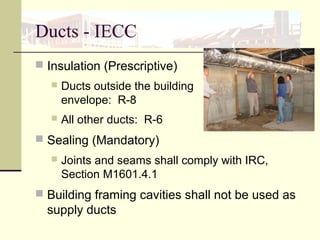

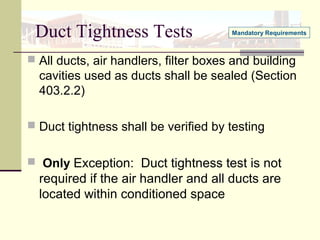

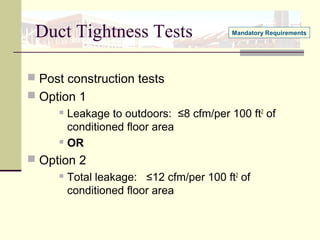

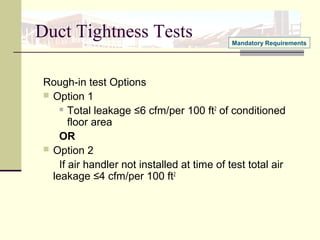

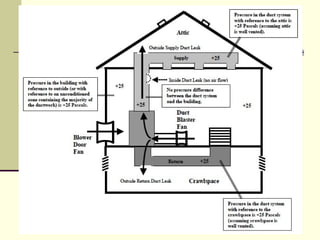

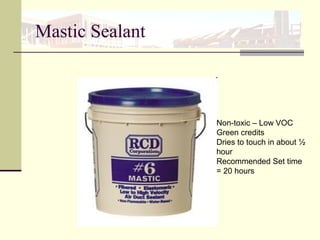

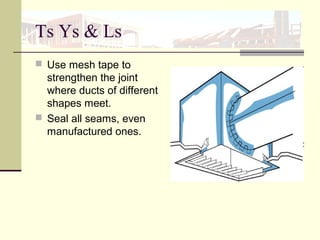

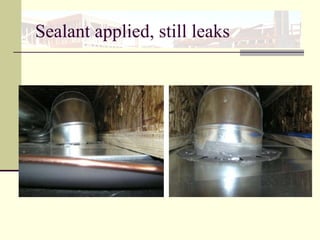

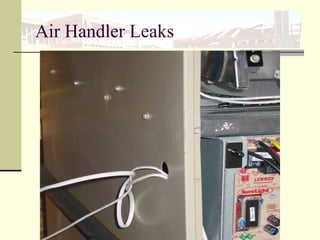

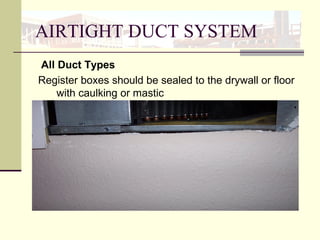

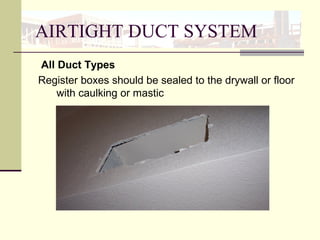

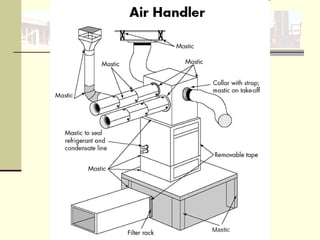

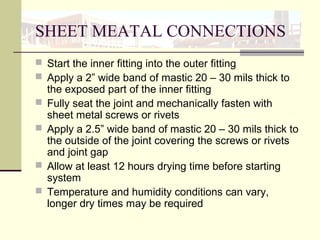

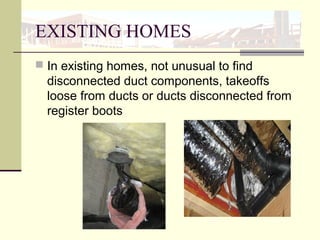

The document outlines the best practices for HVAC system installation, emphasizing the importance of proper design, duct sealing, and adherence to energy efficiency standards. Key topics include the reduction of energy costs through effective duct sealing, the impact of HVAC system size on performance, and available retrofit programs and rebates. It also highlights the significance of load calculations and manual J protocols to ensure systems are properly sized for optimal efficiency.