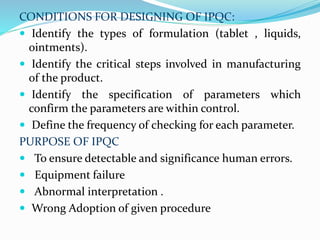

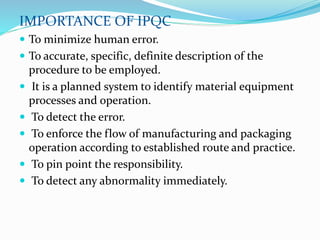

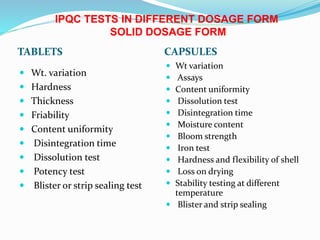

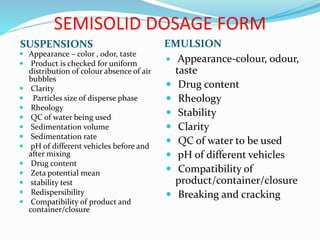

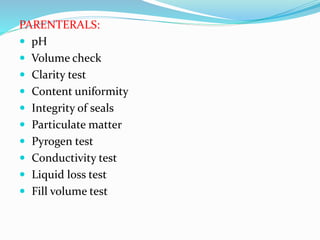

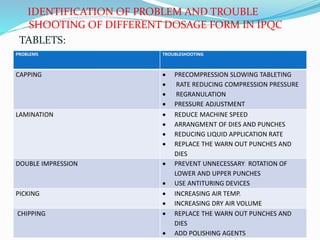

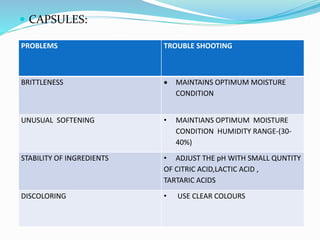

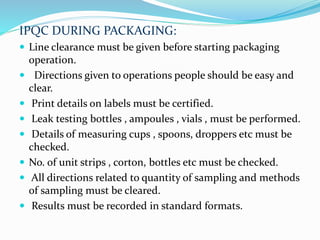

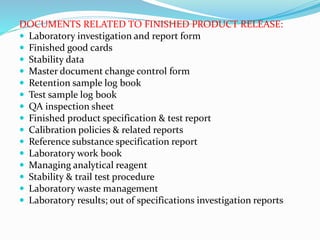

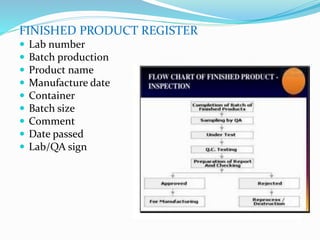

The document summarizes the key aspects of in-process quality control (IPQC), release of finished products, and related quality control procedures. It defines IPQC and discusses the various tests involved at different stages of production. These include physical, chemical, biological, and microbiological testing. It also outlines the documentation required for batch release, including quality review, auditing, and maintaining distribution records. The presentation provides an overview of quality control measures from raw material receipt through finished product release.

![SEMINAR ON

IPQC, RELEASE OF FINISHED PRODUCTS

PRESENTED BY

HUZAIFA NAAZ

H.T.NO.636217885002

M.Pharmacy I year

UNDER GUIDANCE OF

DR. SANDIP SEN

DEPARTMENT OF PHARMACEUTICAL ANALYSIS

SRIKRUPA INSTITUTE OF PHARMACEUTICAL SCIENCES

[Affiliated to Osmania university]

[Approved by PCI; AICTE]](https://image.slidesharecdn.com/qaandqcseminar-180705183724/75/Qa-and-qc-seminar-1-2048.jpg)