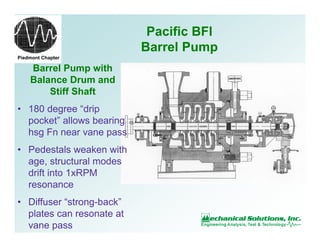

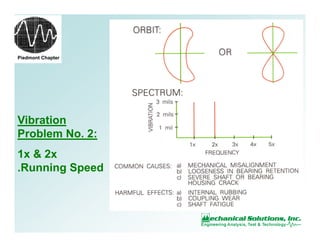

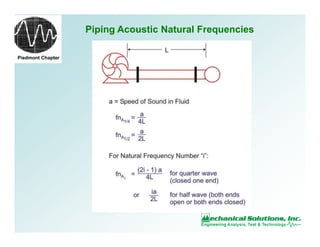

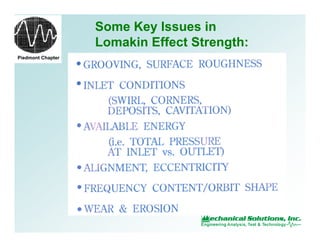

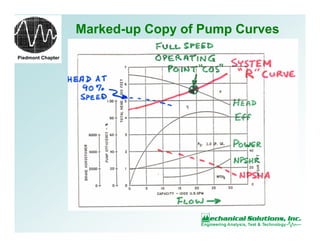

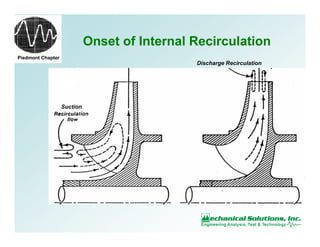

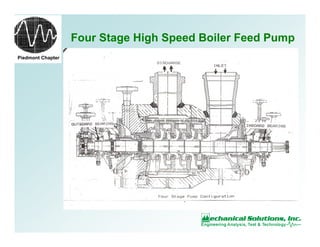

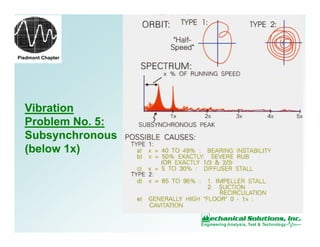

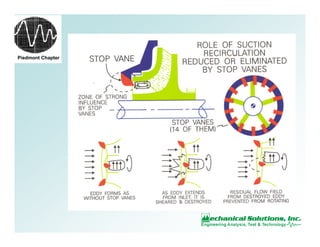

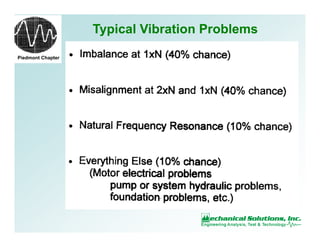

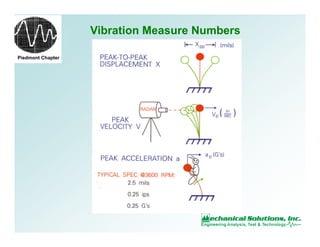

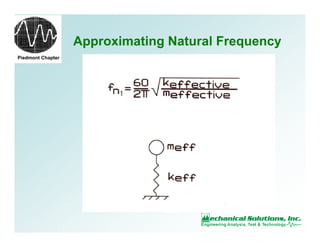

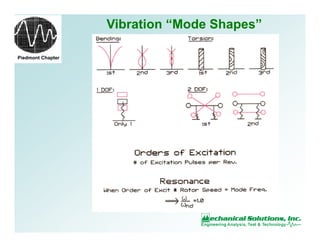

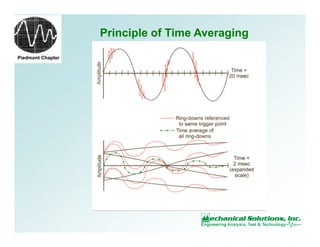

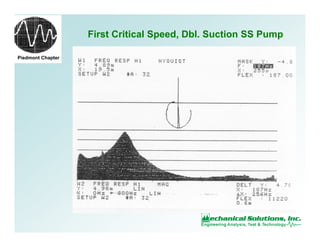

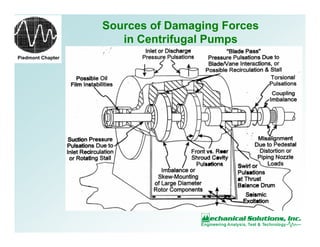

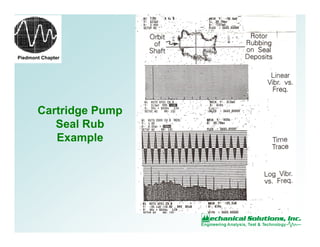

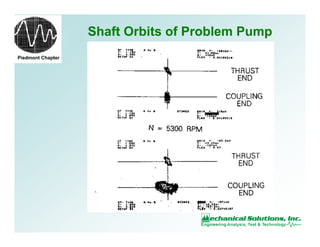

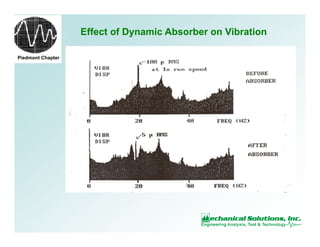

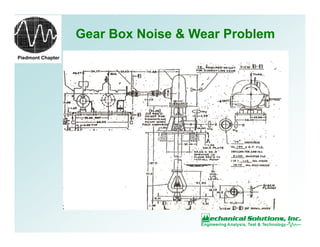

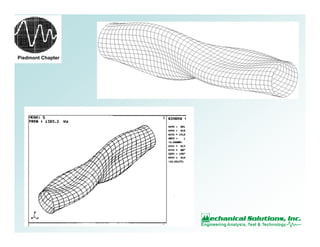

This document summarizes a presentation on pump vibration troubleshooting given to the Piedmont Chapter. It discusses various types of centrifugal pumps and potential vibration issues such as resonances at running speed, vane pass frequency, and subsynchronous frequencies. Specific cases are presented on problems with double suction pumps, vertical turbine pumps, and bearing failures. Modal testing and rotor dynamic analysis are presented as tools to identify natural frequencies and diagnose vibration issues.