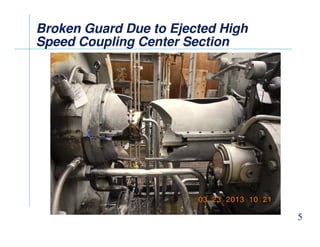

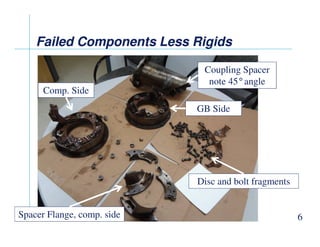

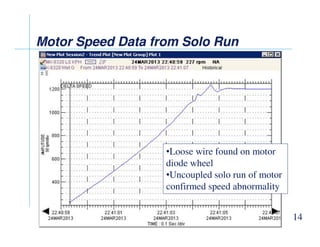

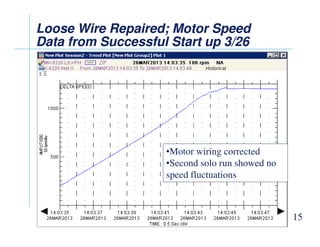

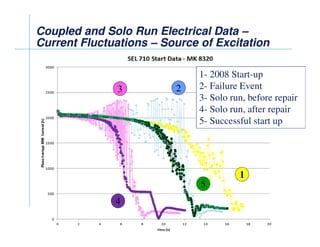

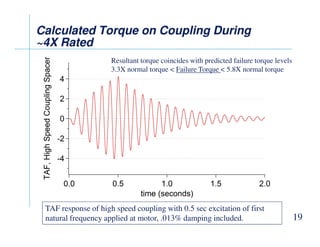

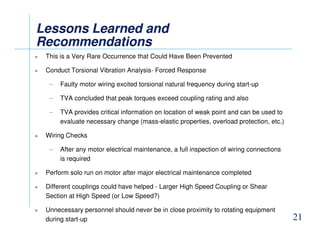

A motor fault caused a coupling failure between an electric motor and gearbox driving a compressor. During startup after maintenance, the motor speed fluctuated, exciting a torsional vibration mode that caused tremendous torque loads over 4 times the rated capacity on the high speed coupling. This caused the compressor side disc pack and spacer to buckle and break apart, ejecting the center section through the guard. A loose wire on the motor diode wheel was found to be the root cause of the speed fluctuations. Ensuring proper wiring after electrical work and evaluating torsional response to transients can prevent such rare but dangerous coupling failures.