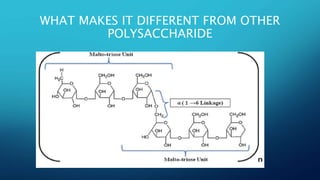

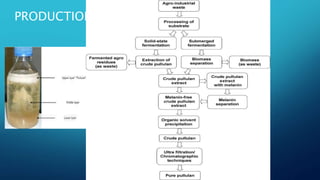

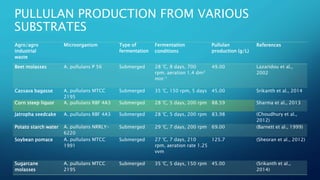

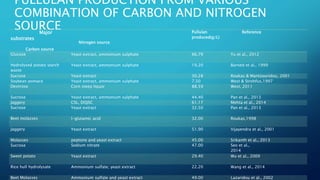

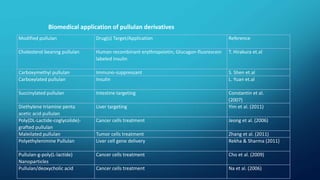

This document discusses a study on the production and optimization of pullulan using different substrates. It finds that jaggery is the best carbon source and corn steep liquor is the best nitrogen source for high pullulan production. Pullulan has various applications including drug delivery, wound dressings, food preservatives, and wastewater treatment. Future areas of research include exploring industrial-scale applications of pullulan in foods and developing metabolic engineering approaches to improve pullulan yields during fermentation.