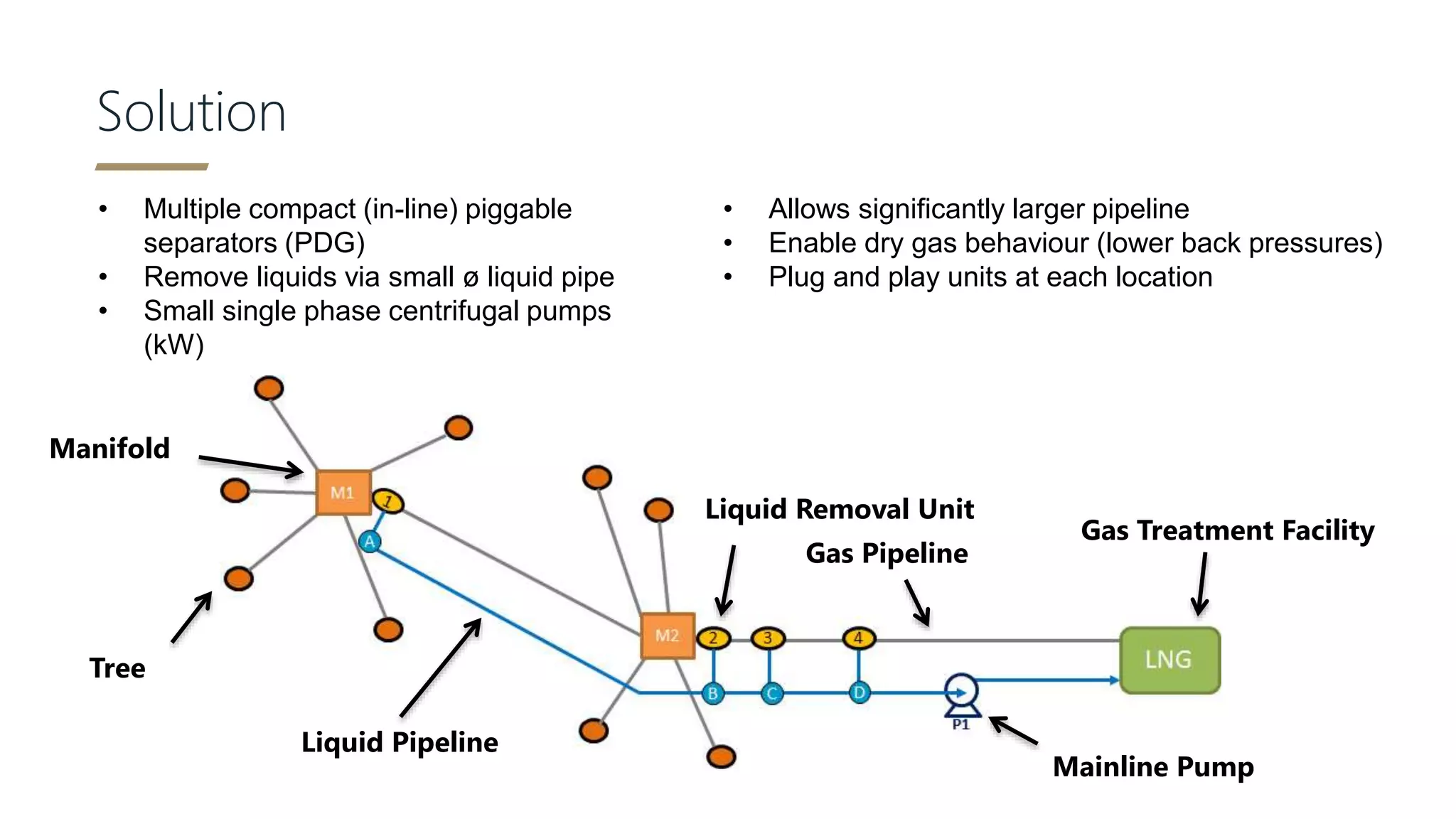

This document presents a Pseudo Dry Gas (PDG) separation technology that can significantly increase the distance that remote gas fields can be tied back to shore. The technology uses compact inline separators and small pumps to remove liquids from the gas stream, allowing larger diameter pipelines that experience lower pressure drops over long distances. A case study shows how applying this technology to a 170km trunkline could increase production by over 160 MMscfd and generate an additional $10 billion in revenue by reducing wellhead pressures. The system is presented as a lower-cost alternative to standard subsea tiebacks or using floating production vessels for fields located further than current tieback limits.