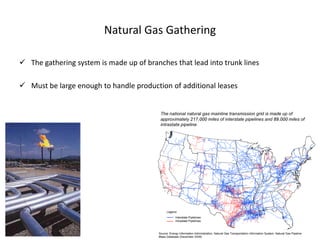

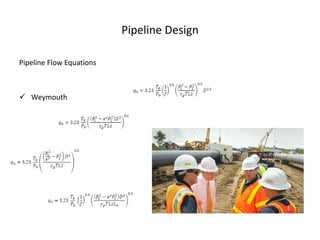

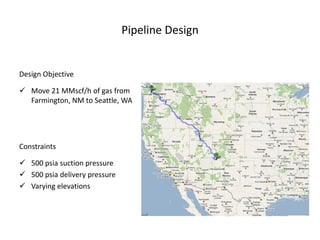

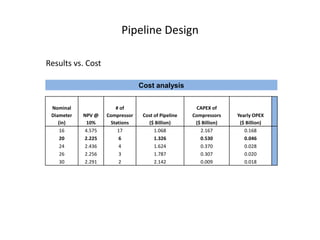

The document discusses the design of a natural gas pipeline from Farmington, New Mexico to Seattle, Washington. It outlines the key components of pipeline systems including pipes, compressor stations, metering stations, valves, and control systems. The document then describes the methodology used to design the pipeline, which included calculating pipe length and number of compressor stations needed based on flow equations, cities' distances and elevations. Finally, it presents the results of a cost analysis which recommended a 20-inch diameter pipeline with 6 compressor stations as the most economical solution.