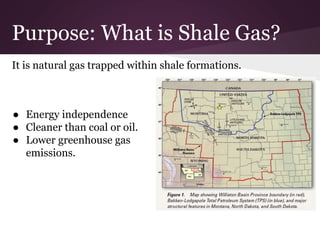

The document outlines a proposed gas treatment plant with the following key points:

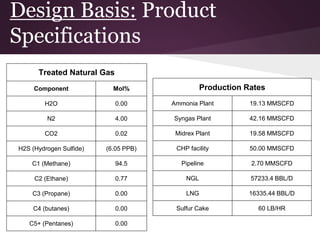

- The plant would process raw shale gas from the Bakken formation to produce compressed natural gas, liquefied natural gas (LNG), and natural gas liquids (NGL) for various uses.

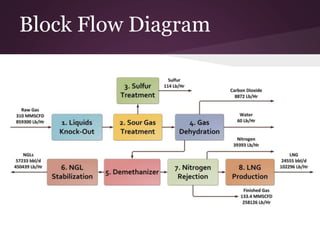

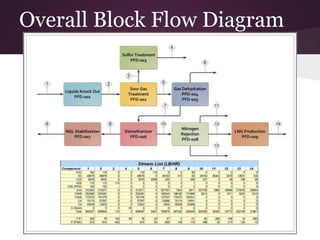

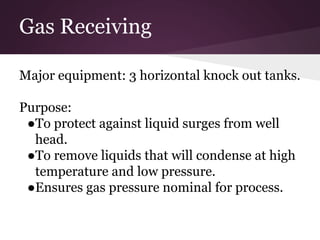

- Major processes would include sour gas treatment to remove hydrogen sulfide, dehydration, demethanization, NGL stabilization, and nitrogen rejection via cryogenic distillation.

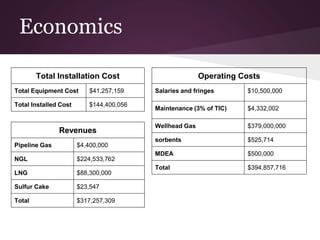

- Economics analysis shows total annual revenues of $317 million against operating costs of $395 million, with a total installed capital cost of $144 million.

- Key recommendations are for the plant to move forward given its importance in supplying gas to other