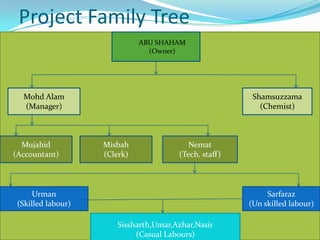

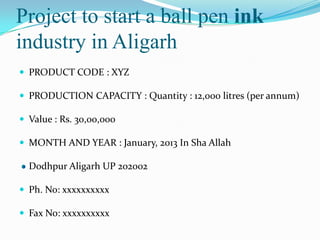

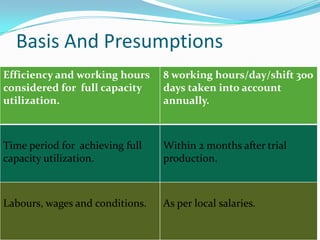

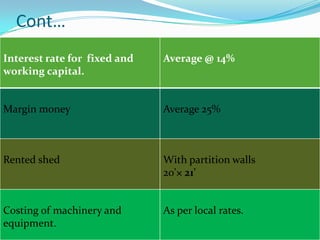

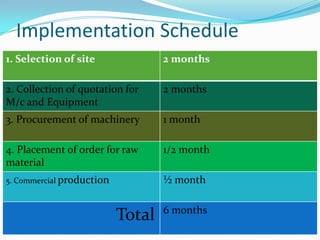

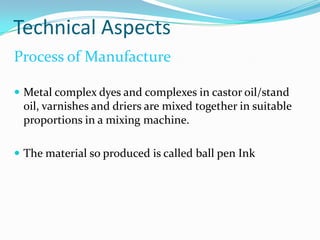

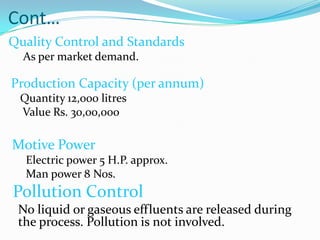

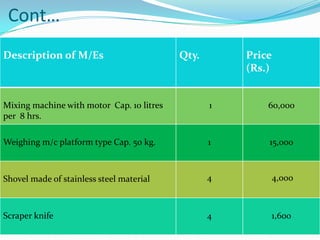

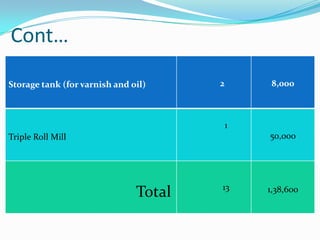

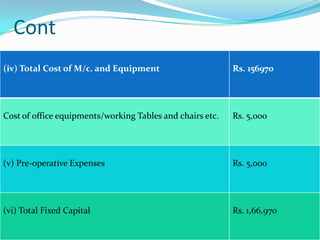

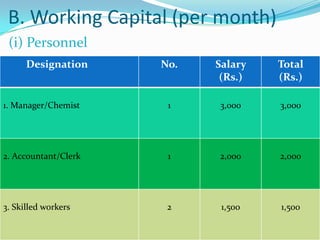

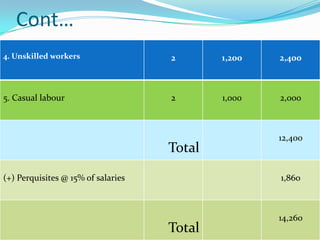

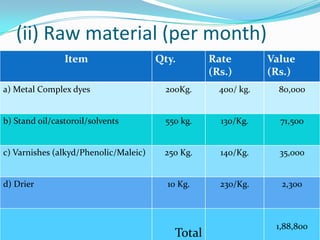

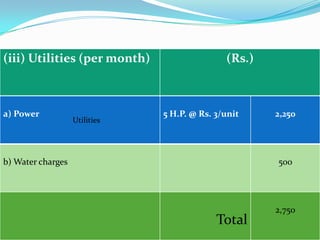

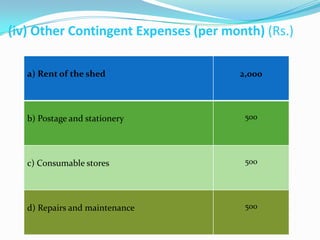

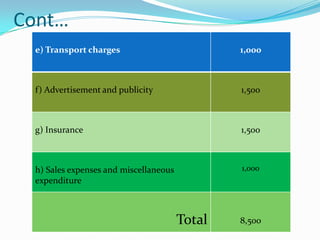

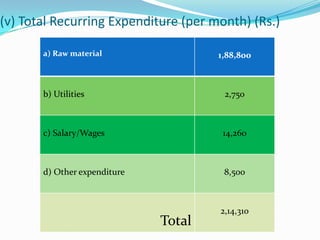

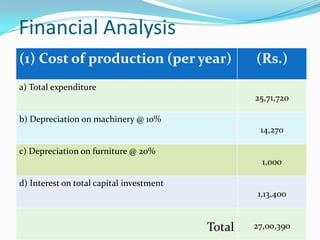

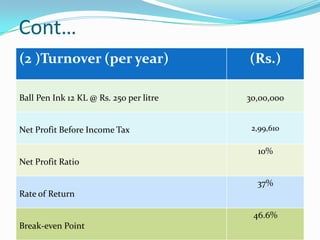

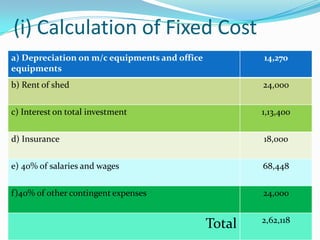

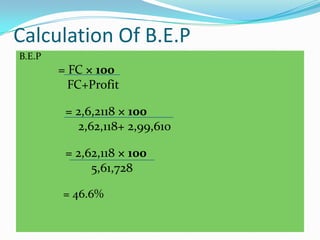

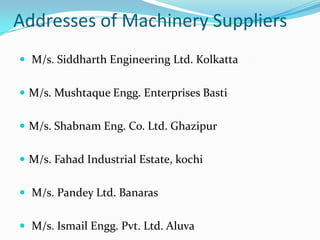

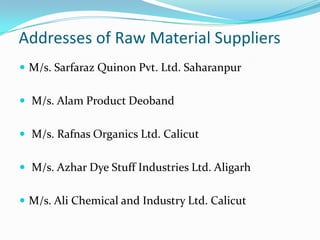

The document provides details of a proposed project to start a ball pen ink industry in Aligarh, India. It includes information on the production capacity, implementation schedule, technical production process, financial aspects including total capital investment and projected profits, and addresses of machinery and raw material suppliers. The key points are that the project would produce 12,000 litres of ball pen ink per year, require a total capital investment of Rs. 8,09,900, and is estimated to generate a net profit of Rs. 2,99,610 in the first year.