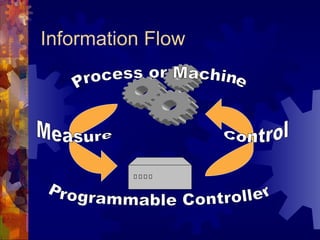

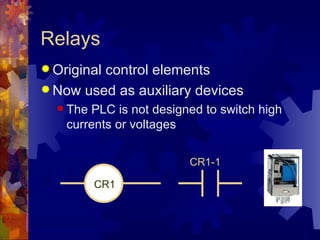

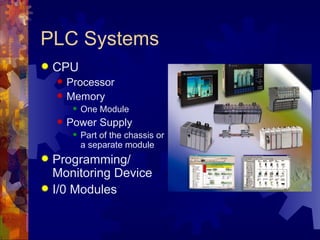

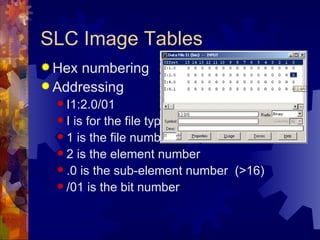

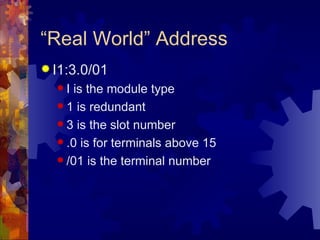

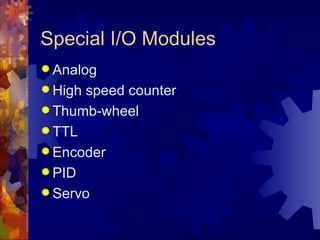

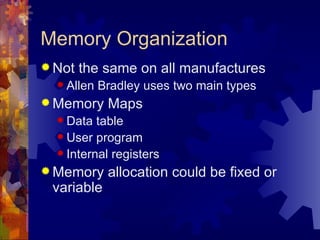

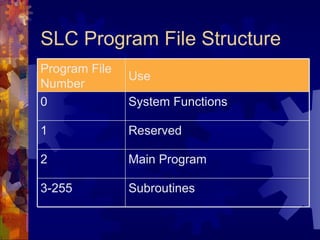

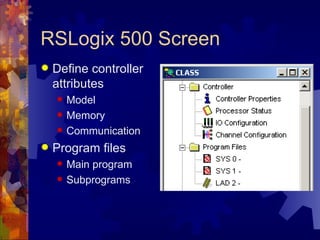

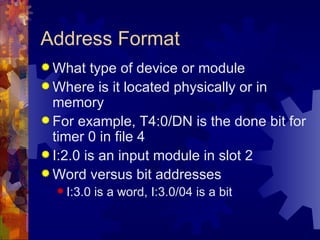

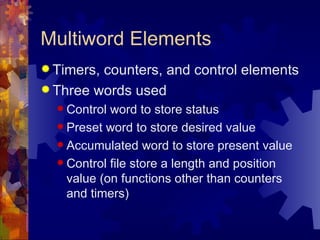

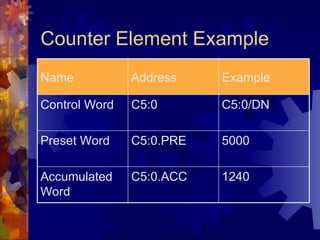

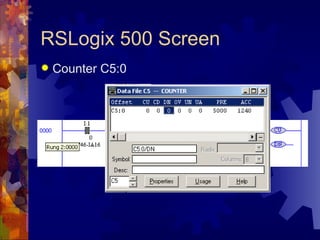

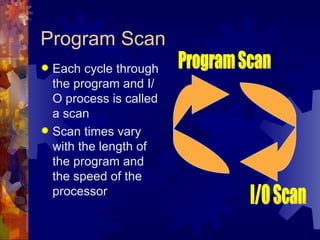

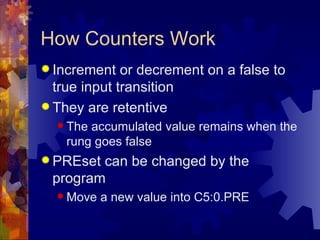

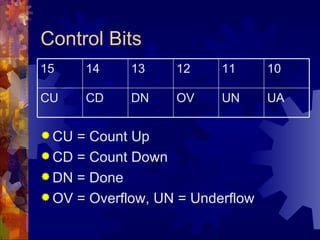

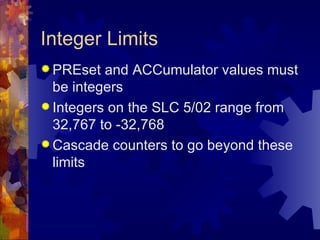

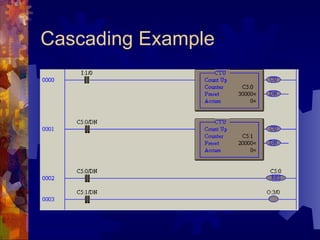

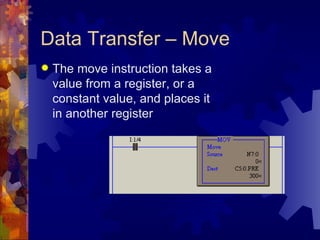

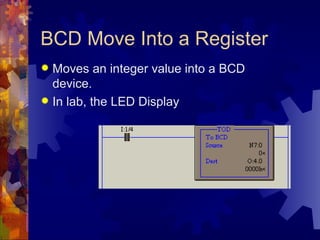

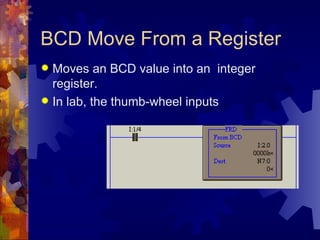

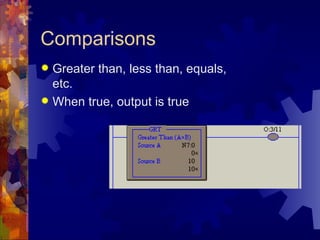

This document provides an overview of programmable logic controllers (PLCs) and their history and applications. It discusses how the first PLC was developed by General Motors in 1968 to replace a relay-based system. It also covers PLC components like the CPU, I/O modules, memory organization, and programming environments. Additional topics include sensors, discrete and analog I/O, addressing schemes, programming instructions like moves, comparisons, and counters. The purpose is to introduce students to basic PLC programming concepts.