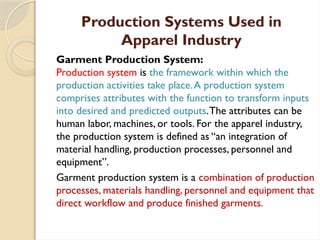

Production system is the framework within which the production activities take place. A production system comprises attributes with the function to transform inputs into desired and predicted outputs. The attributes can be human labor, machines, or tools. For the apparel industry, the production system is defined as “an integration of material handling, production processes, personnel and equipment”.