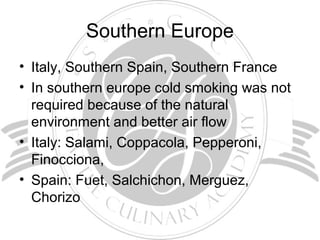

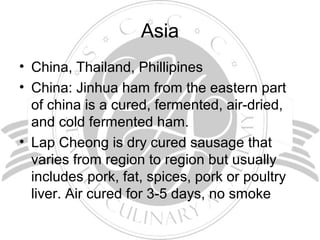

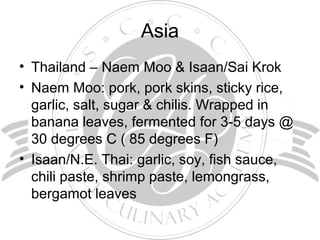

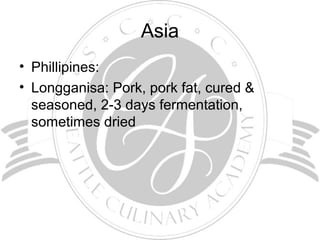

Air-cured and fermented sausages have a long history as a preservation method involving curing, fermenting, smoking, drying, and storage. Curing with salt and nitrates prevents bacterial growth like botulism. Fermentation uses salt to encourage beneficial bacteria like lactobacilli that produce lactic acid, lowering the pH and inhibiting other bacteria. Commercial starter cultures began in 1957 and include fast or slow cultures for different styles. Controls on time, temperature, acidity, moisture, and salt levels are used to reduce spoilage and pathogenic bacteria growth while encouraging beneficial bacteria during the process. Traditional styles vary regionally in Europe and Asia.