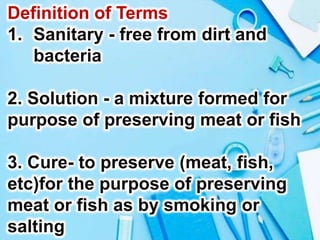

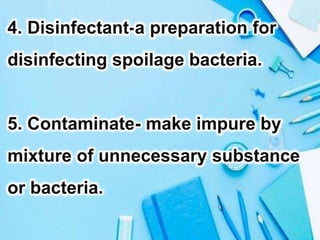

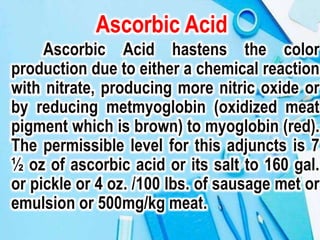

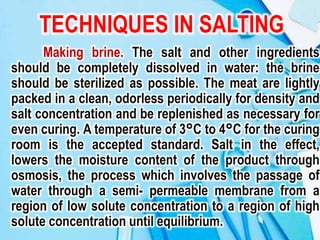

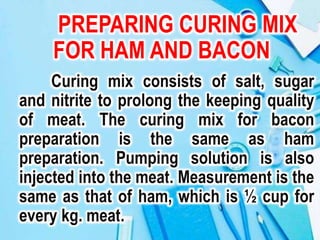

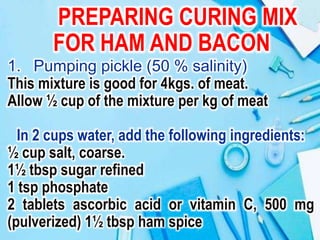

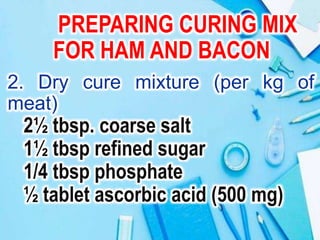

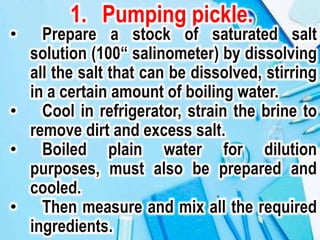

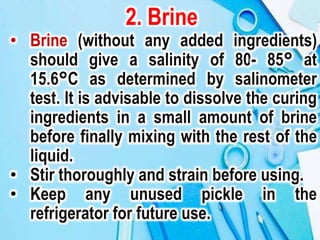

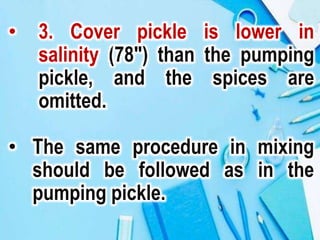

The document outlines essential practices and definitions related to salting and curing in food handling. It emphasizes sanitary food handling procedures, the roles of various curing ingredients like salt and sugar, and techniques for preparing curing mixes for meat products. Best practices for food handlers, including avoiding contamination and accurate measurement of ingredients, are also discussed.