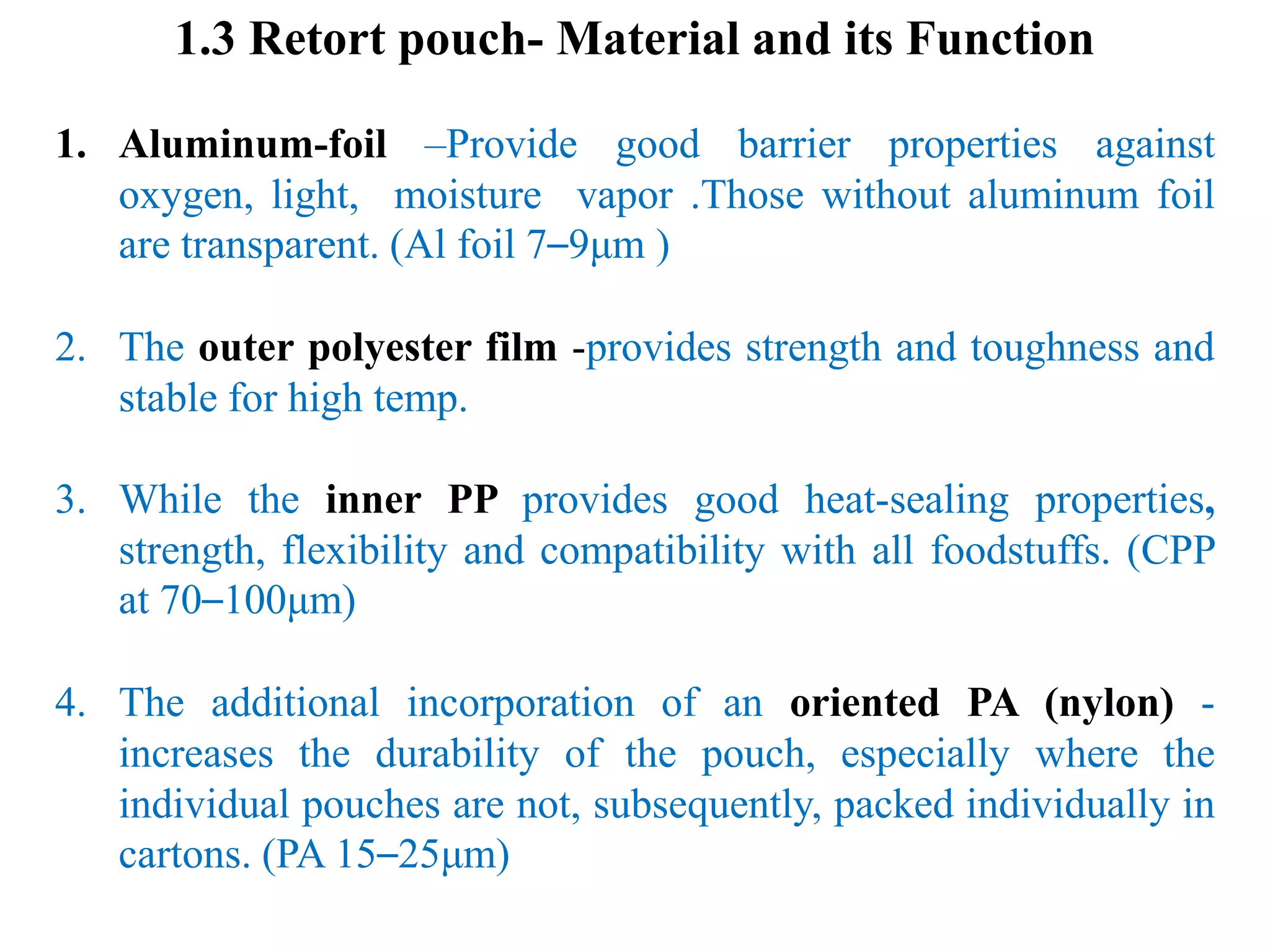

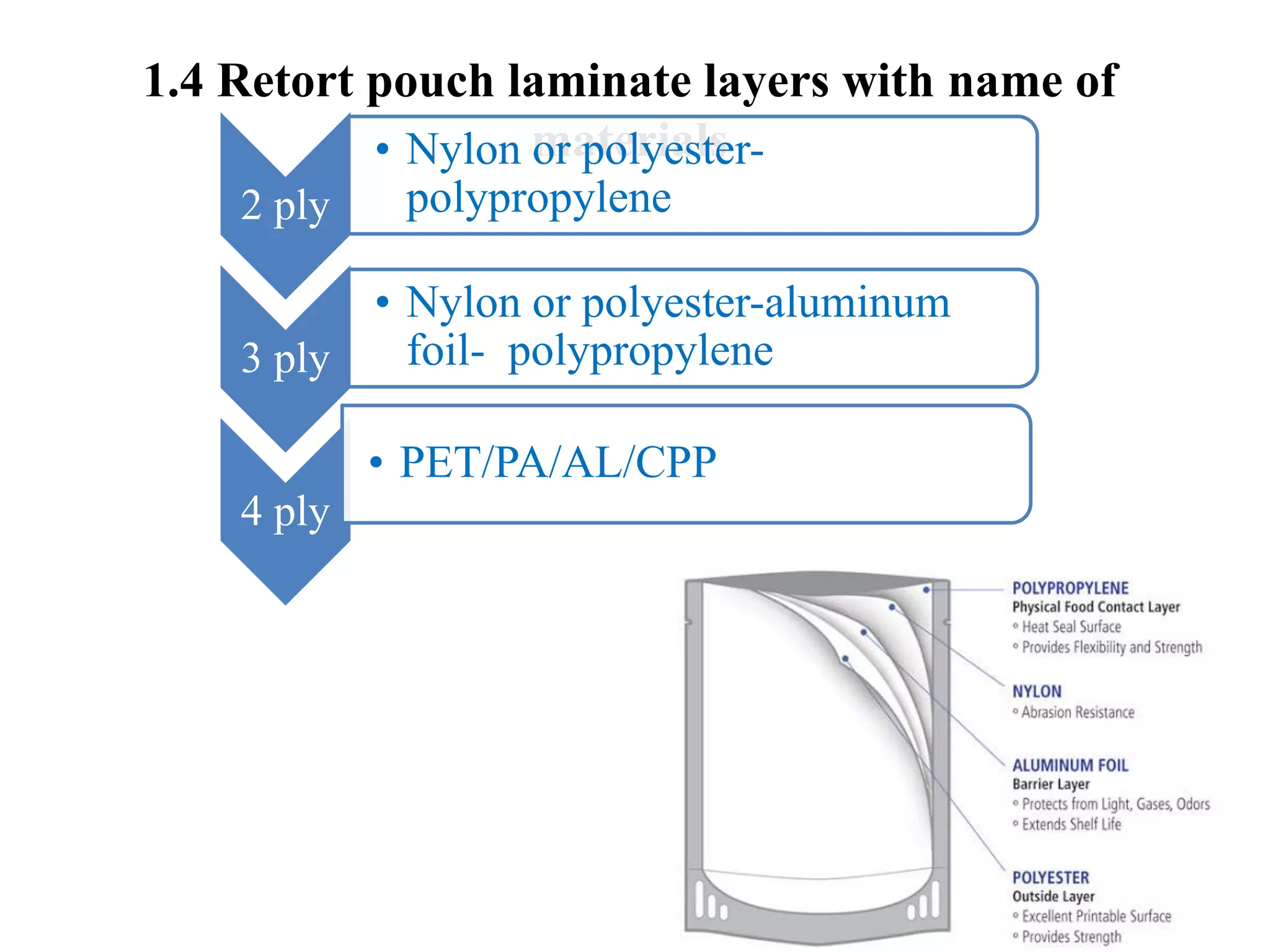

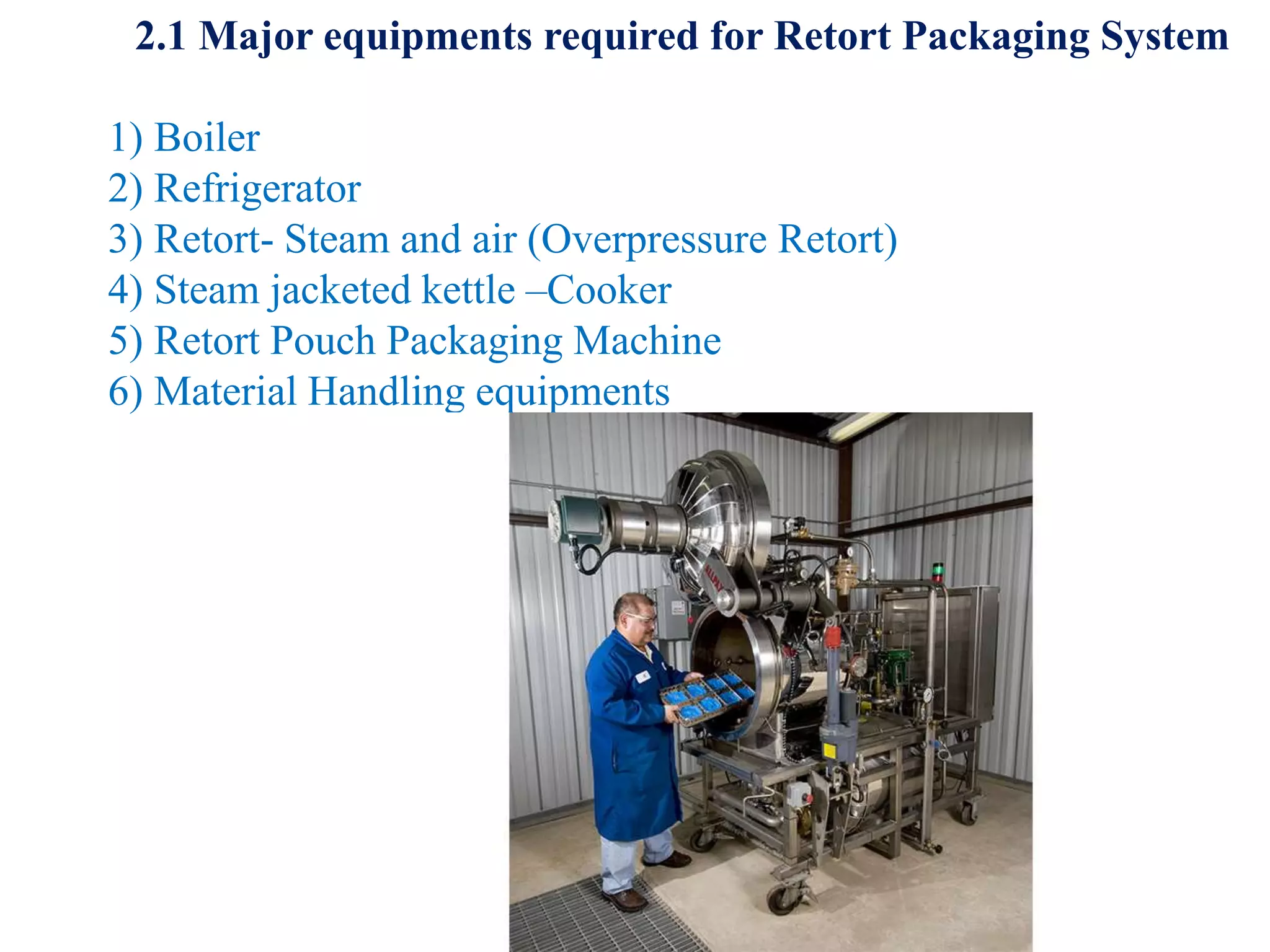

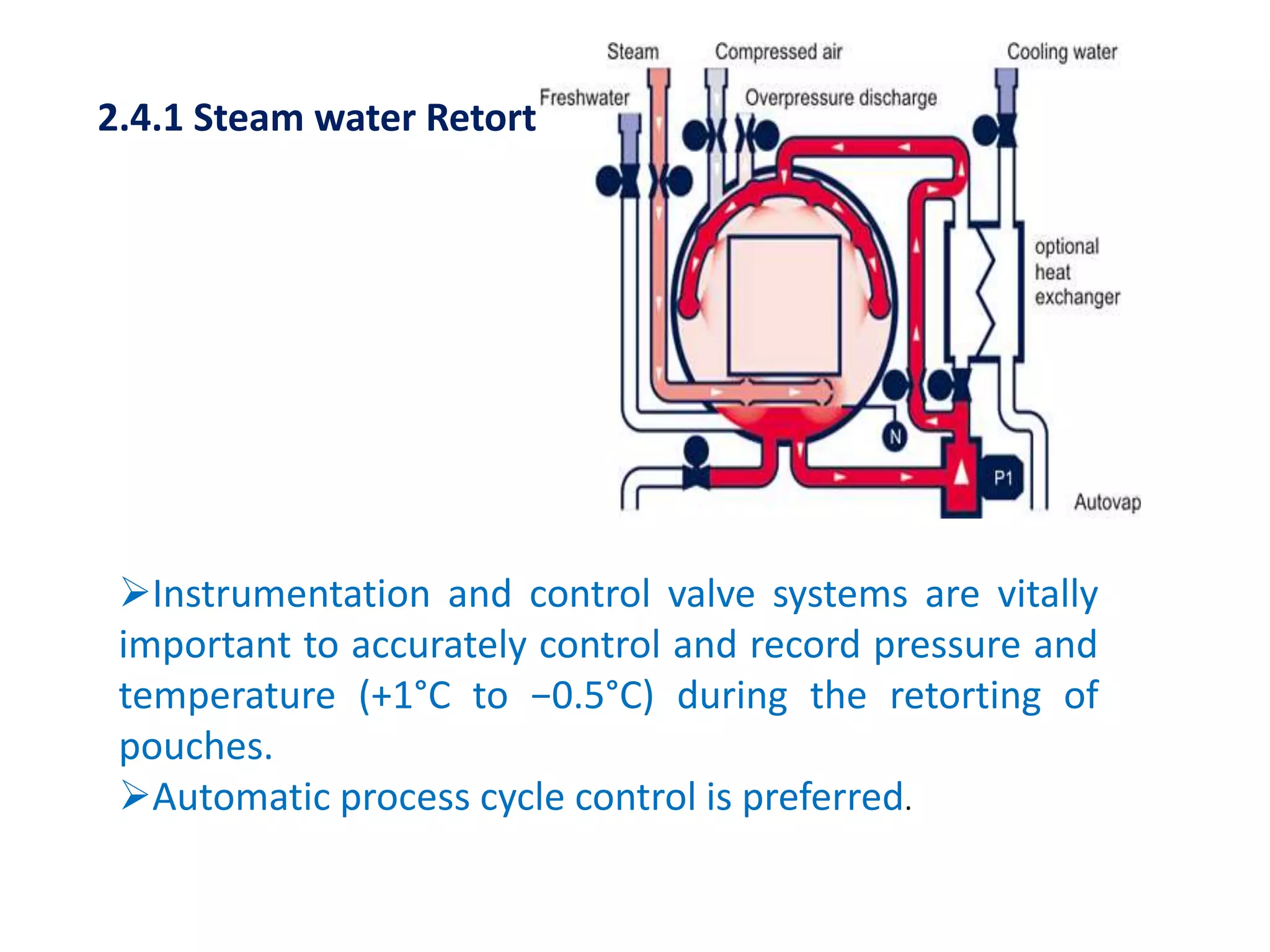

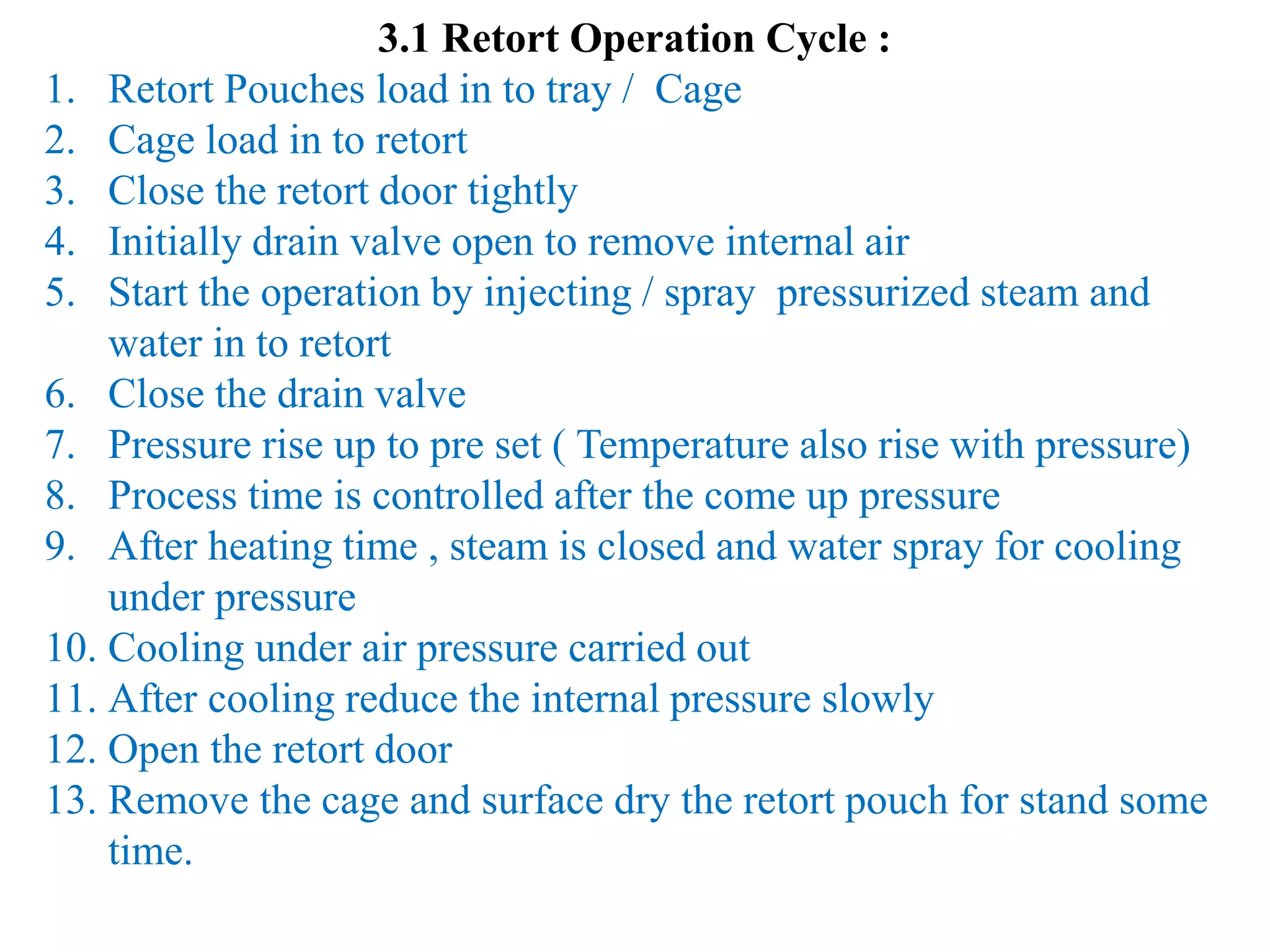

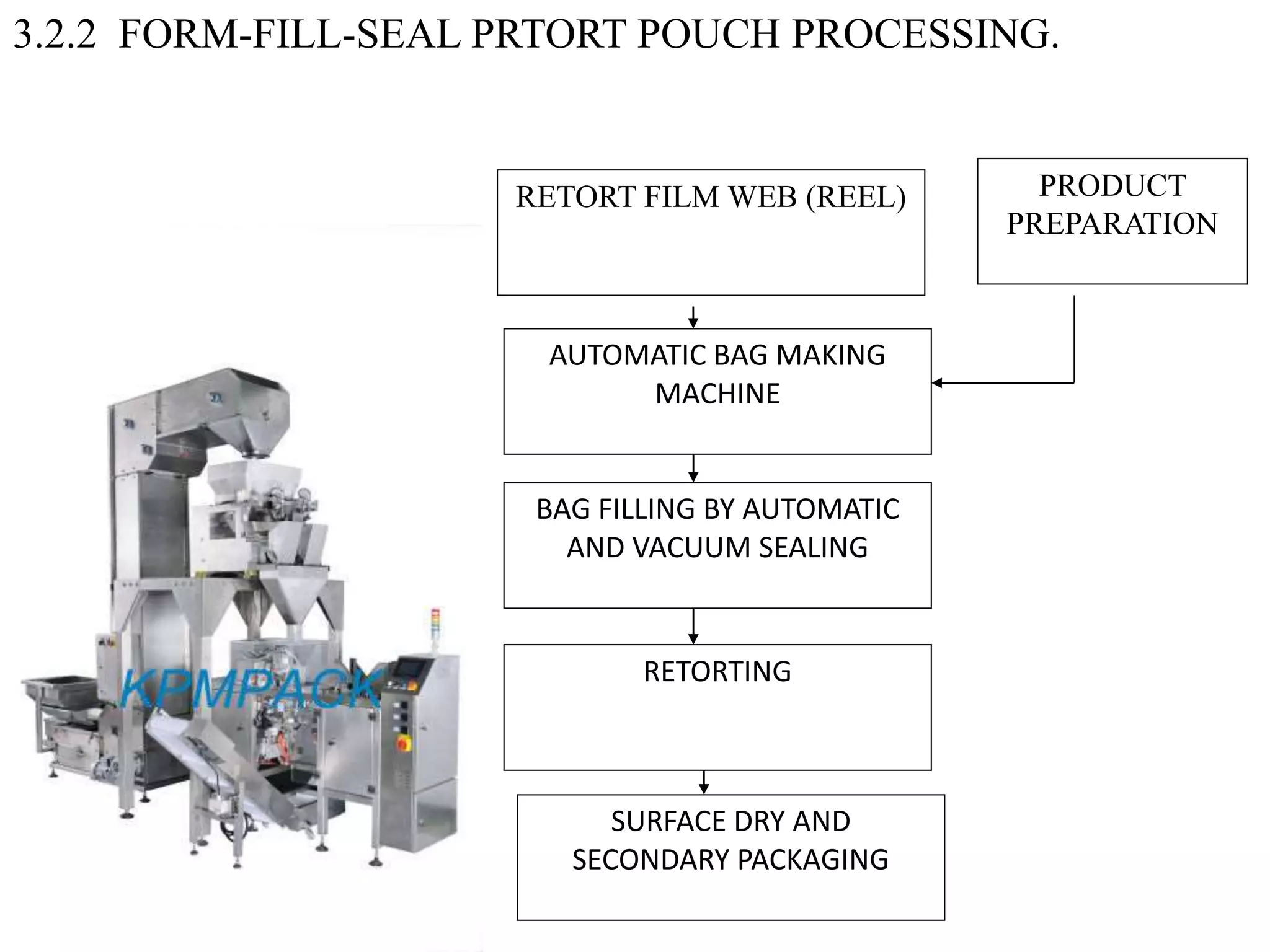

The document outlines the definition, application, materials, properties, and manufacturing processes of retort pouch packaging. It highlights the advantages of retort pouches over traditional metal cans and glass bottles, including low energy requirements and ambient shelf stability. Additionally, it details the required equipment and operational procedures for effective retort pouch processing.