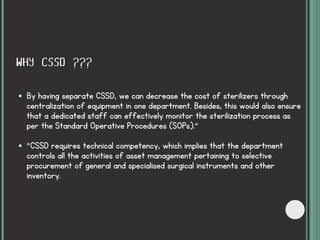

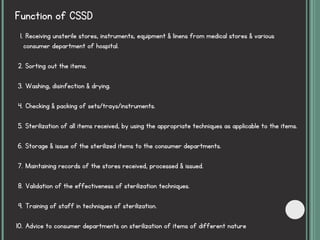

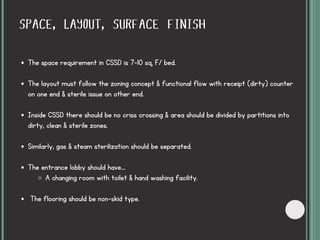

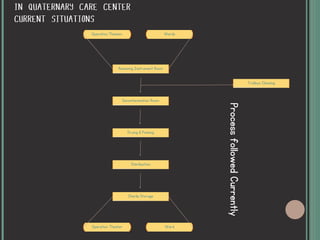

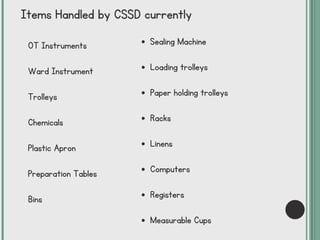

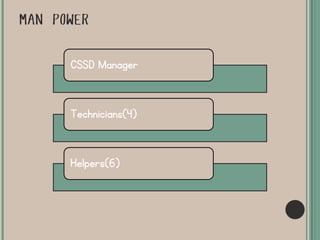

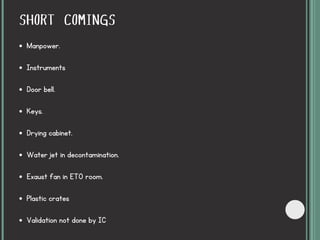

The Central Sterile Supply Department (CSSD) is vital for managing and processing sterile supplies in hospitals, focusing on receiving, cleaning, and distributing surgical instruments according to standardized protocols. Improved CSSD functions reduce nosocomial infections, lower costs, and enhance the efficiency of surgical operations across various departments. Quality management, adequate space, and trained staff are essential components for ensuring reliability and effectiveness in CSSD services.