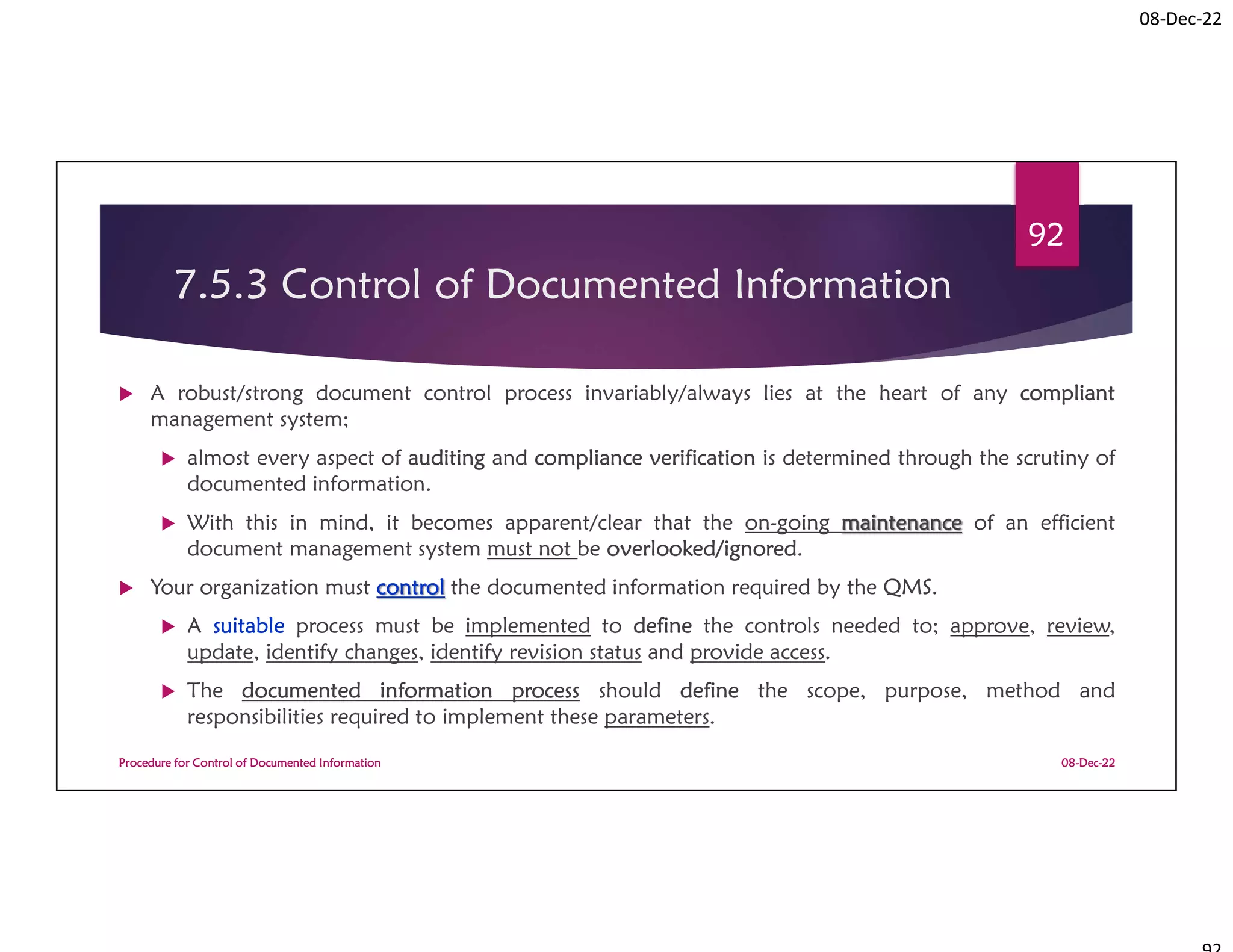

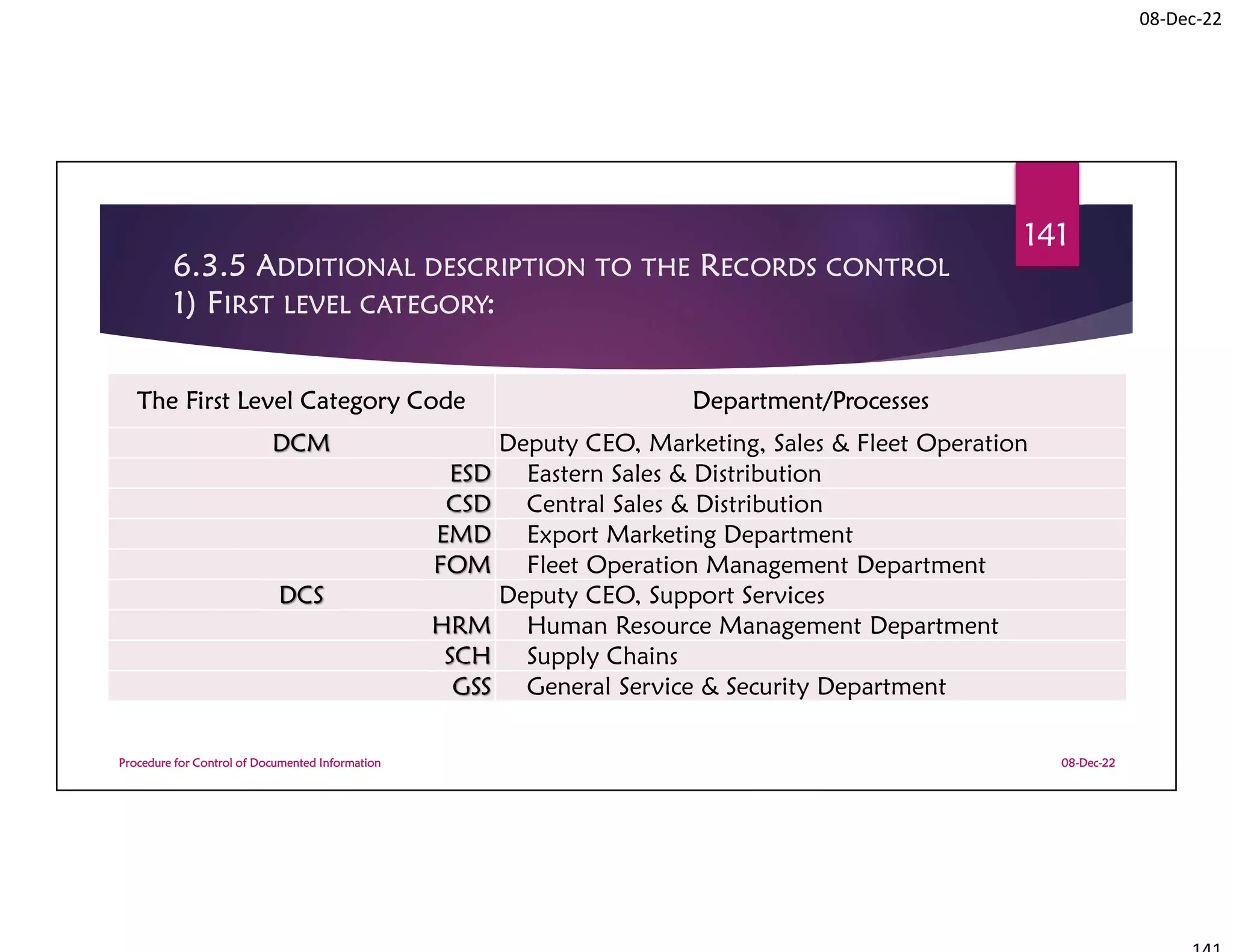

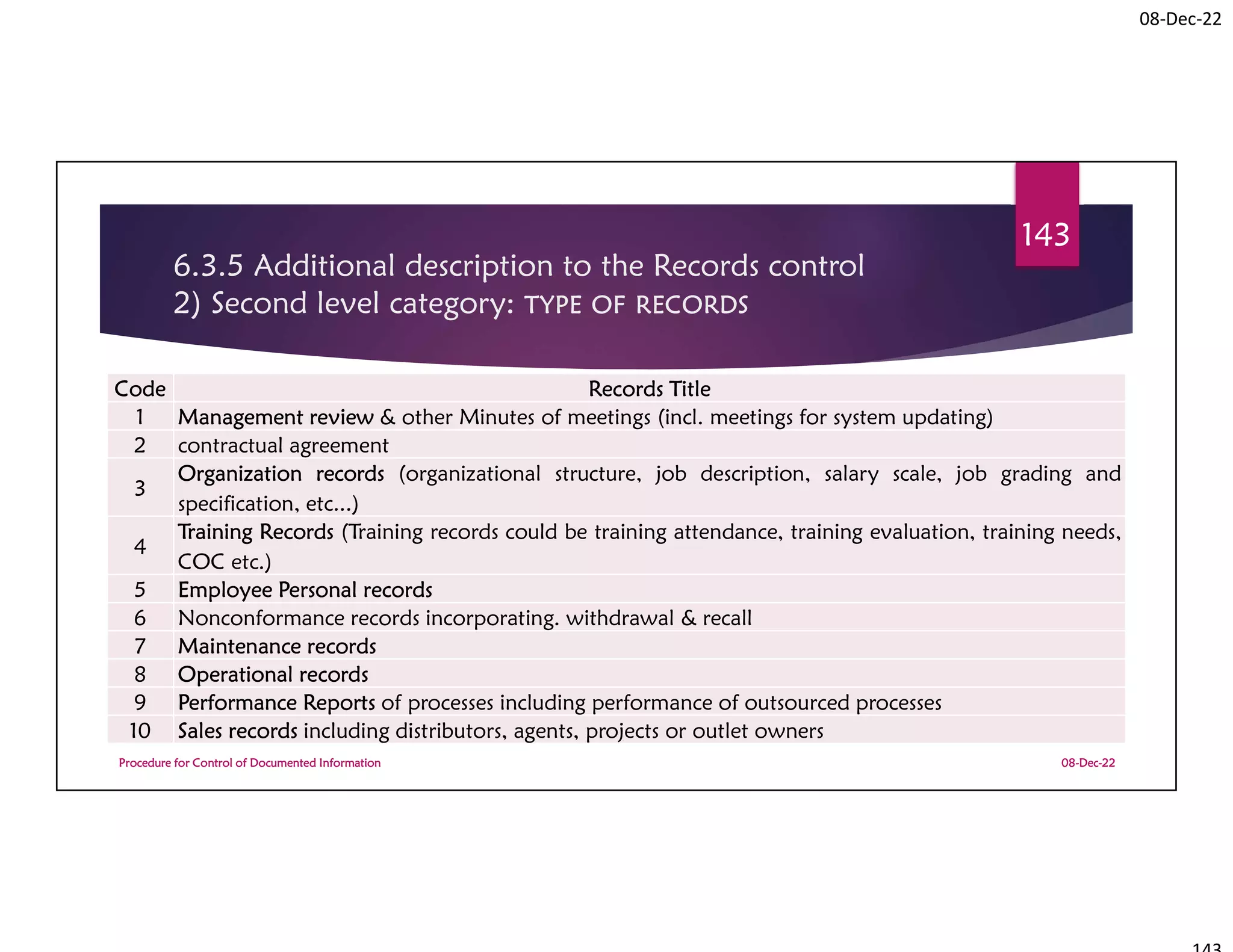

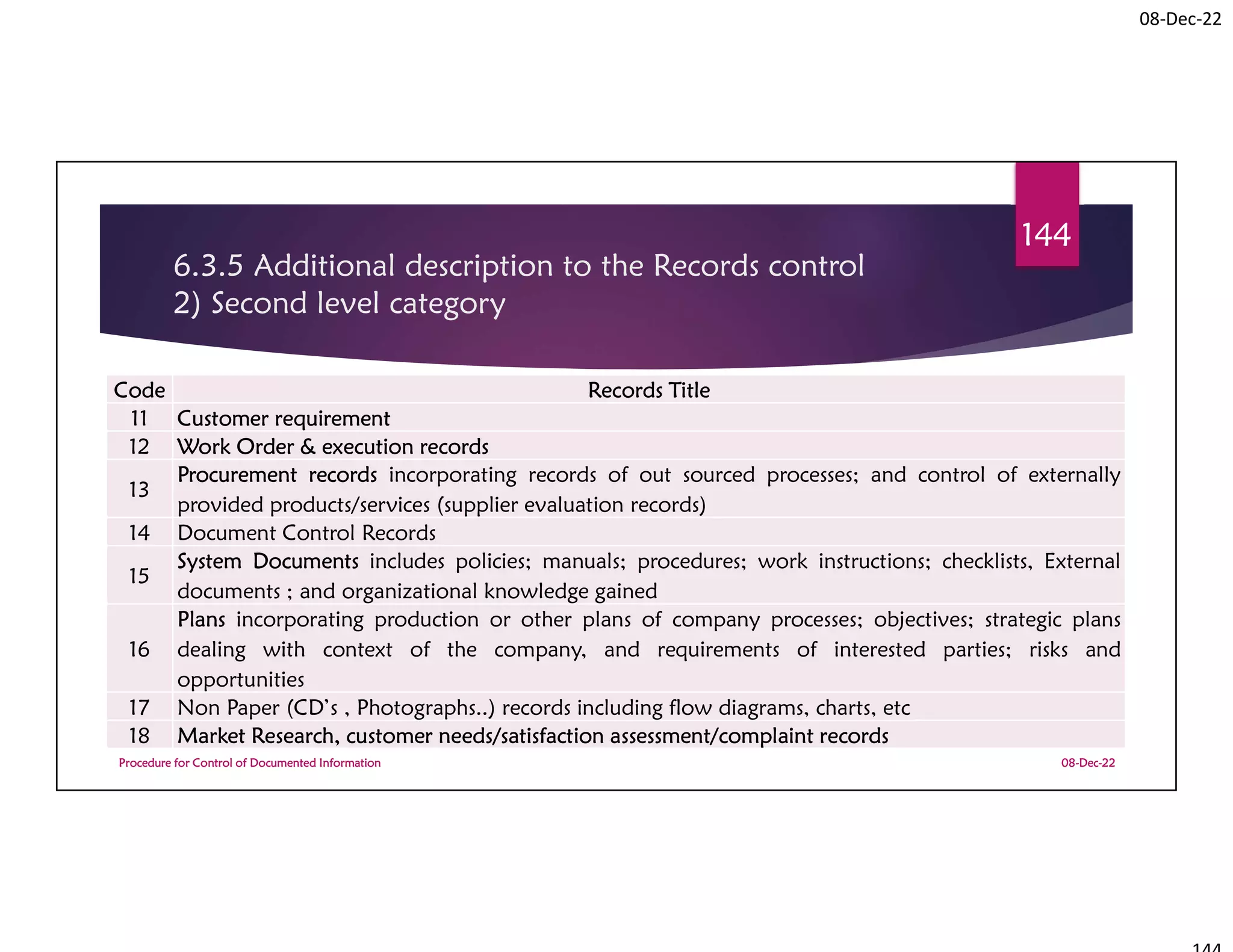

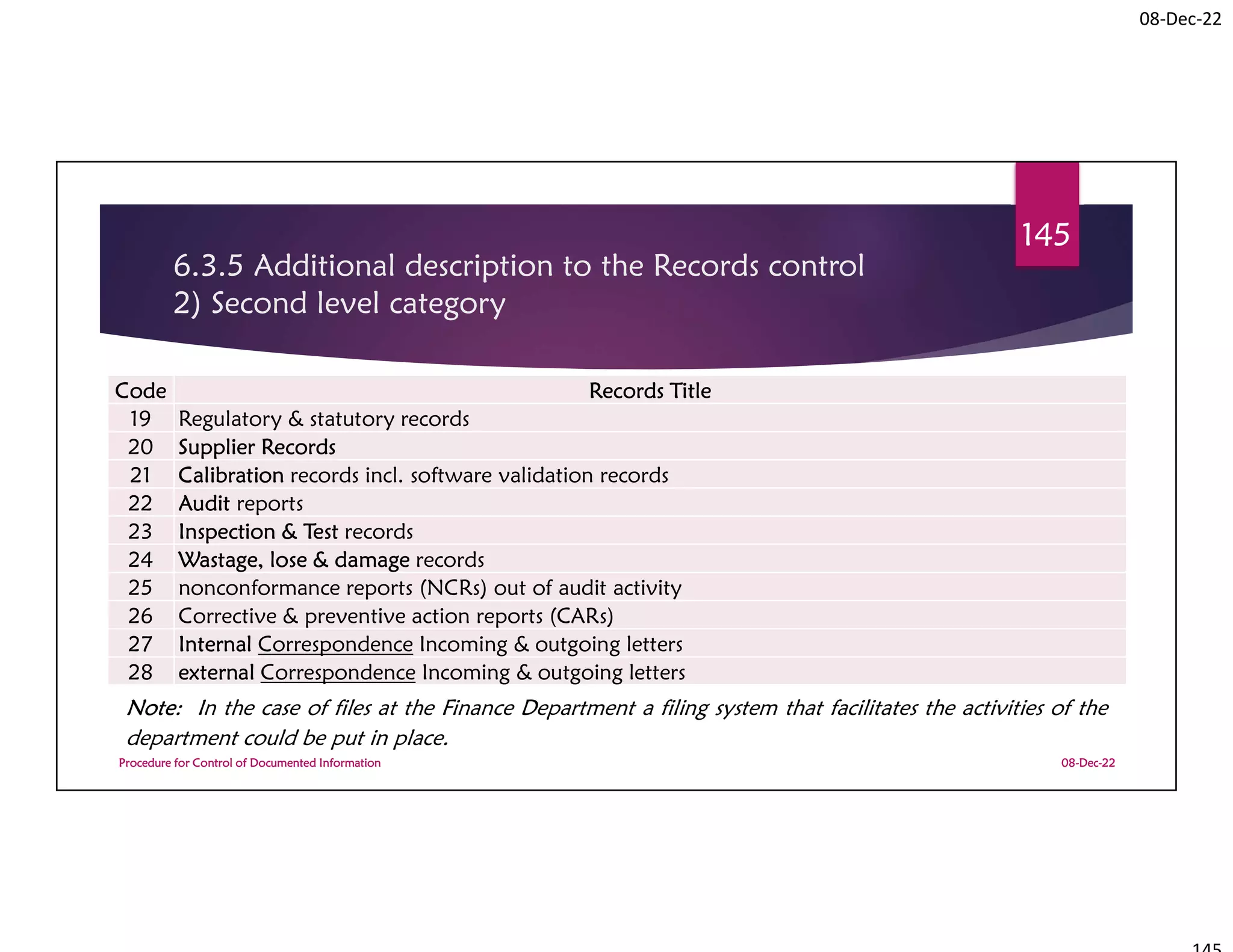

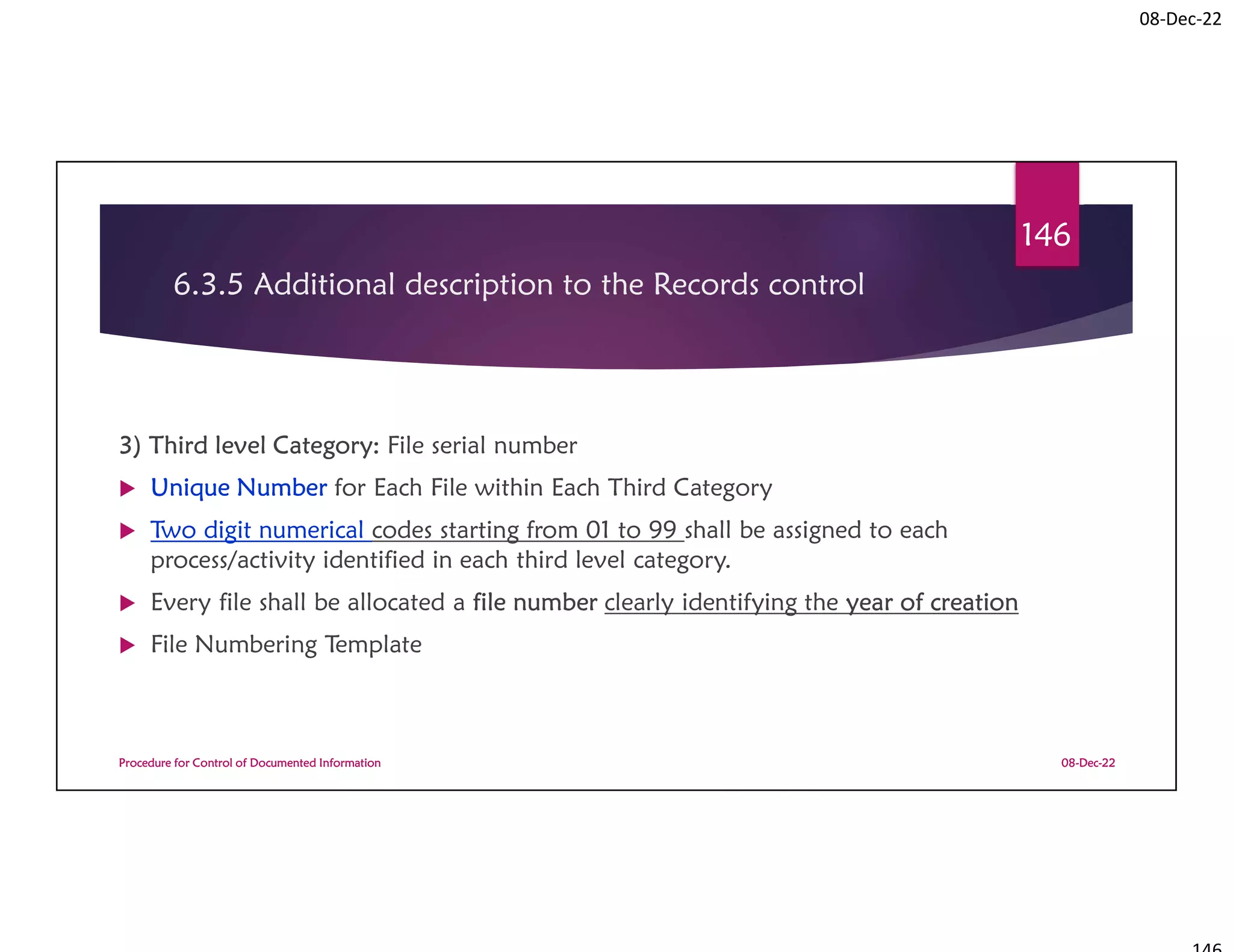

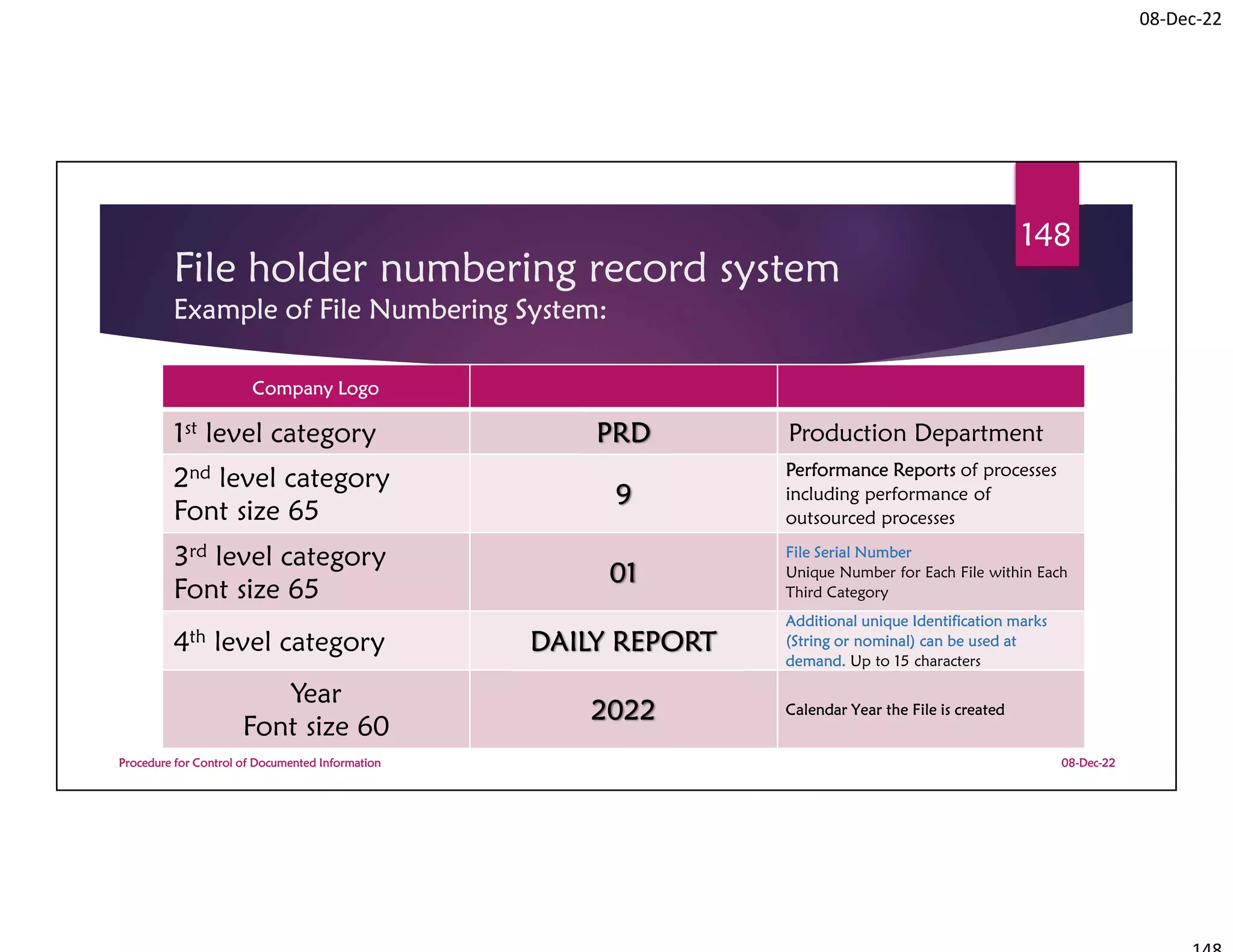

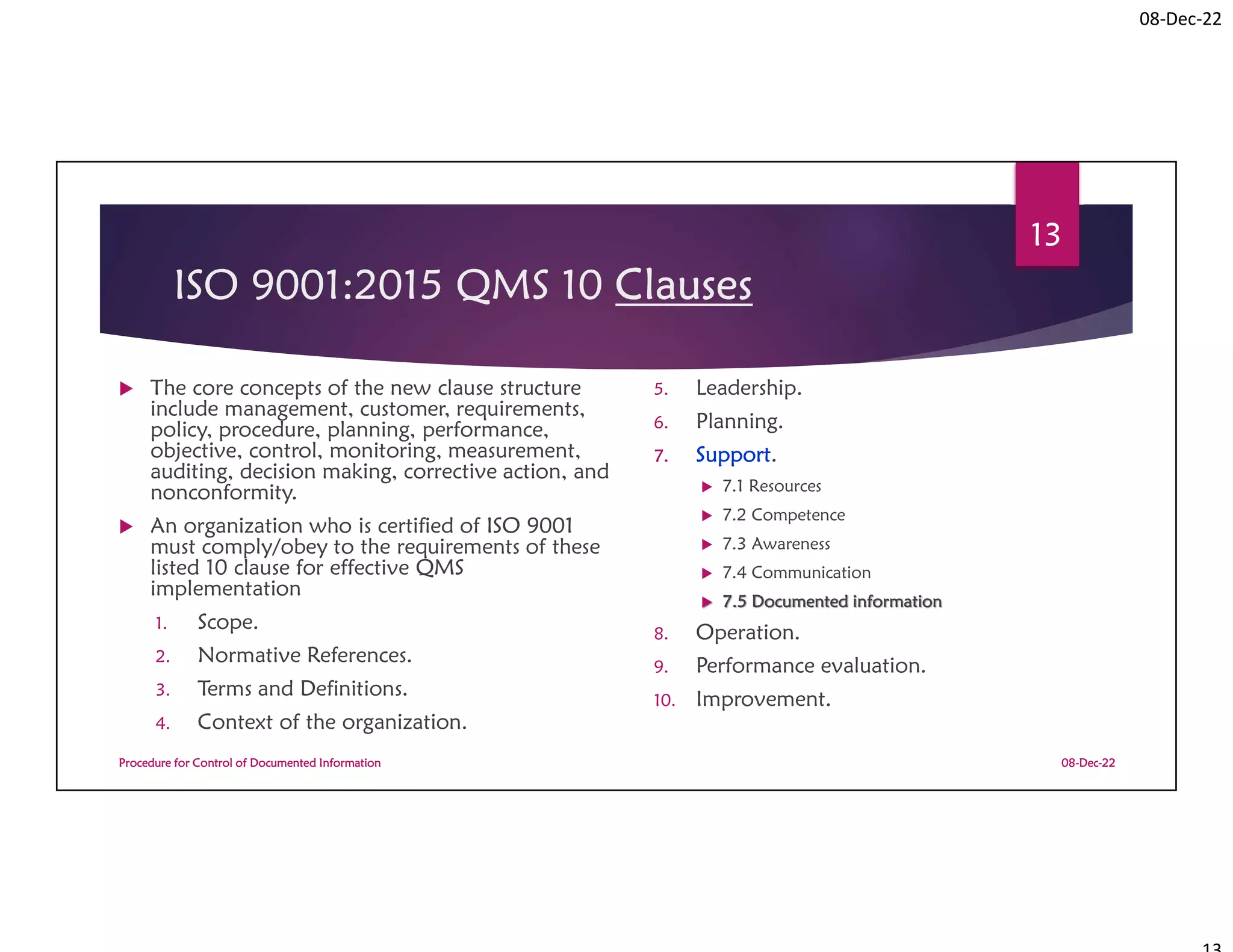

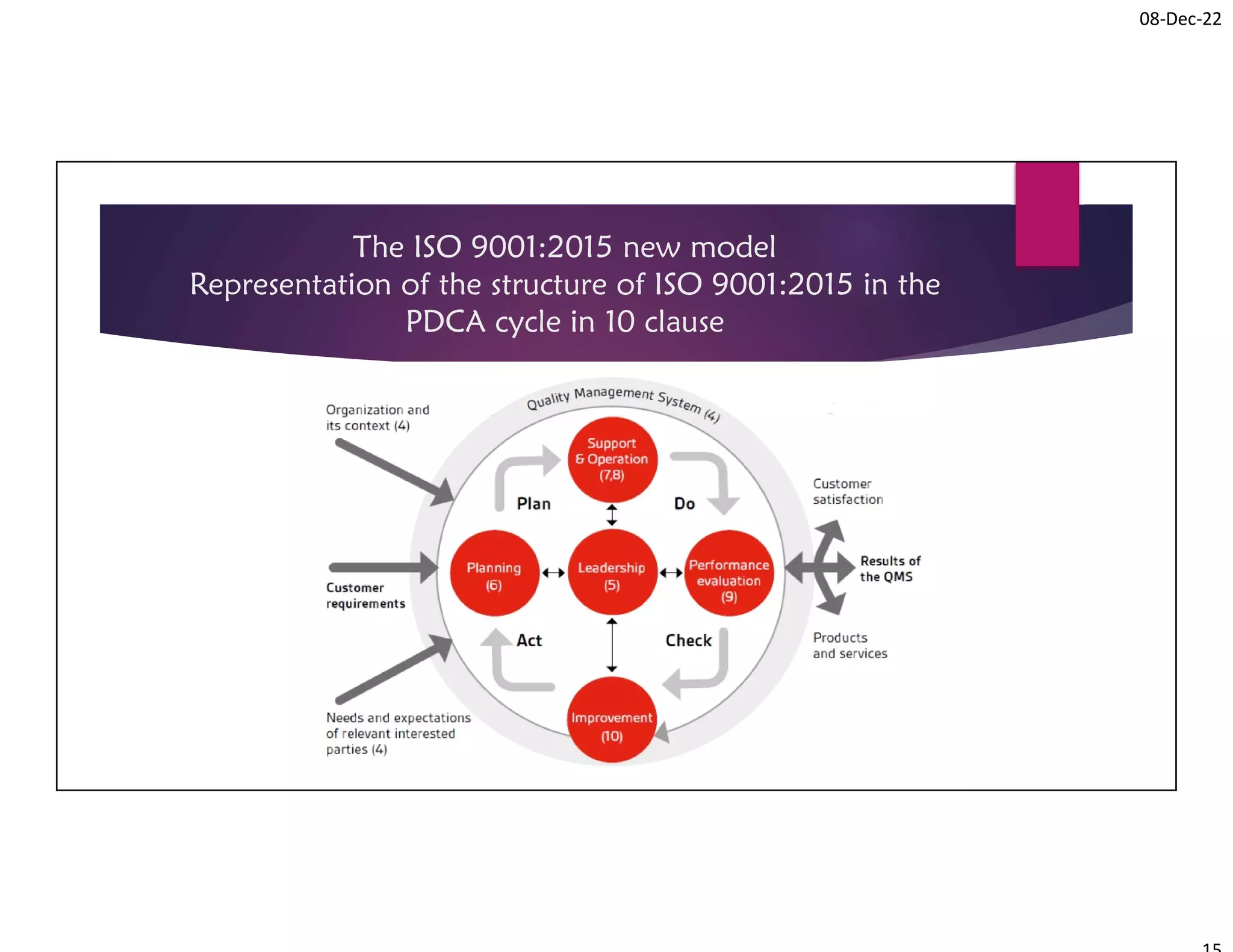

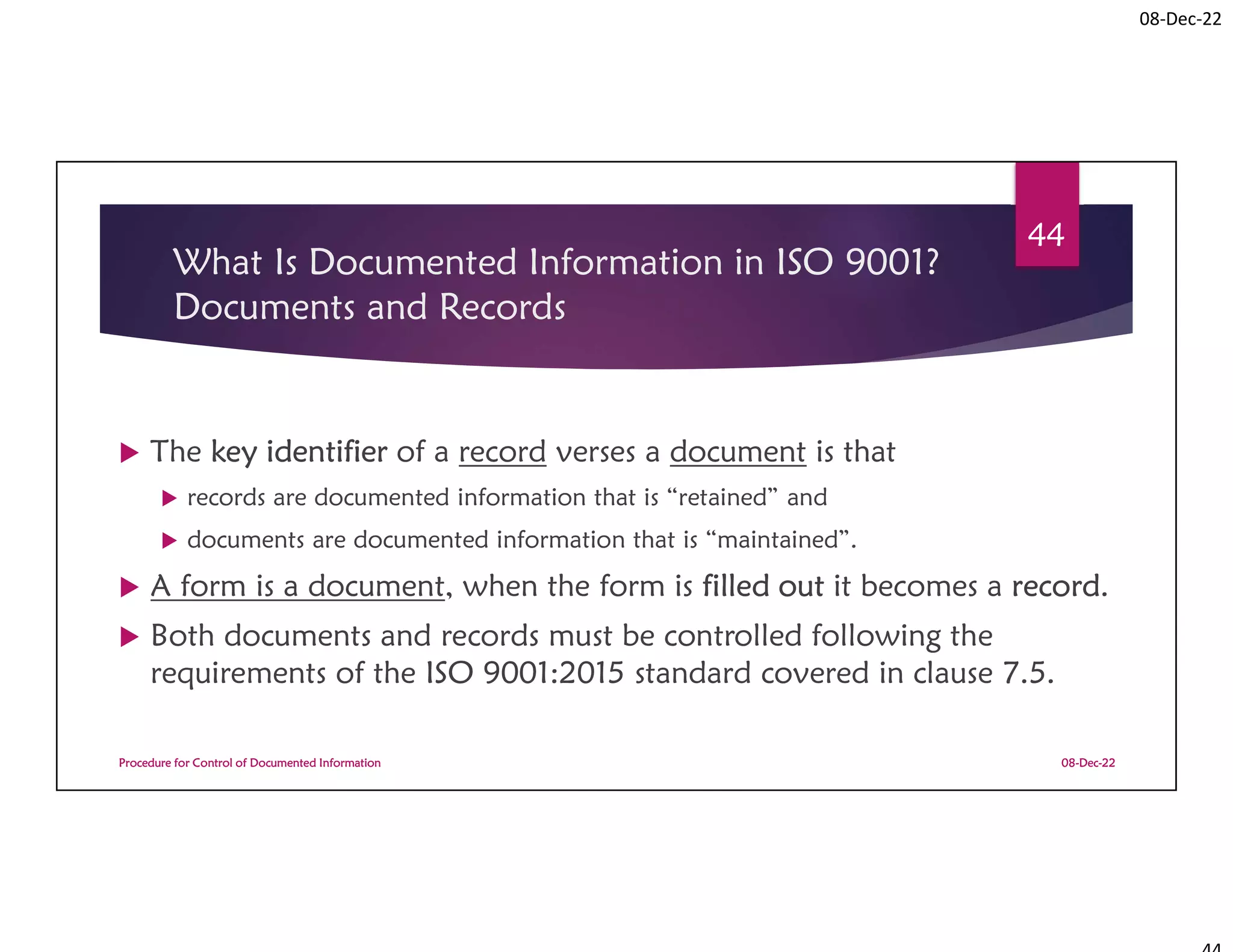

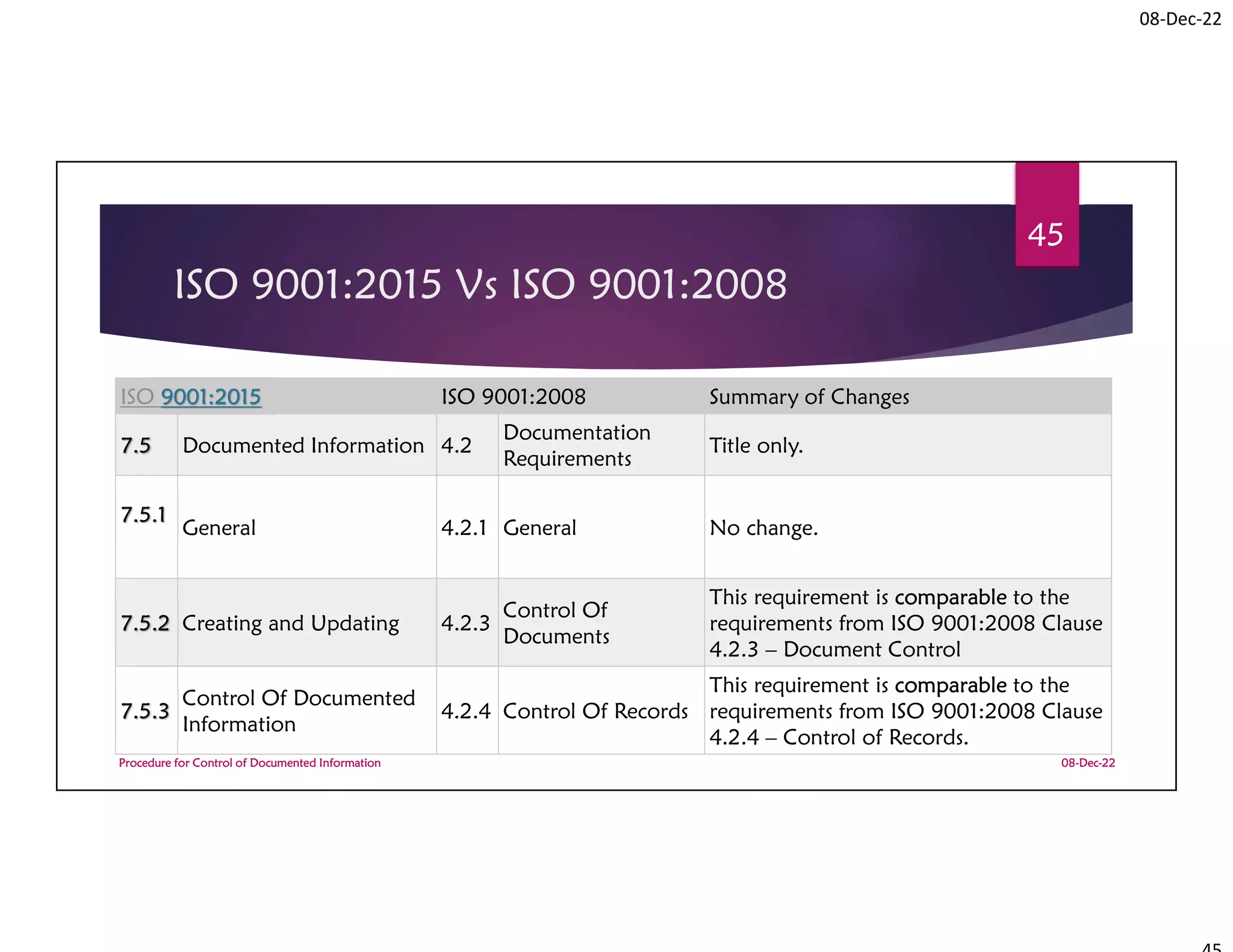

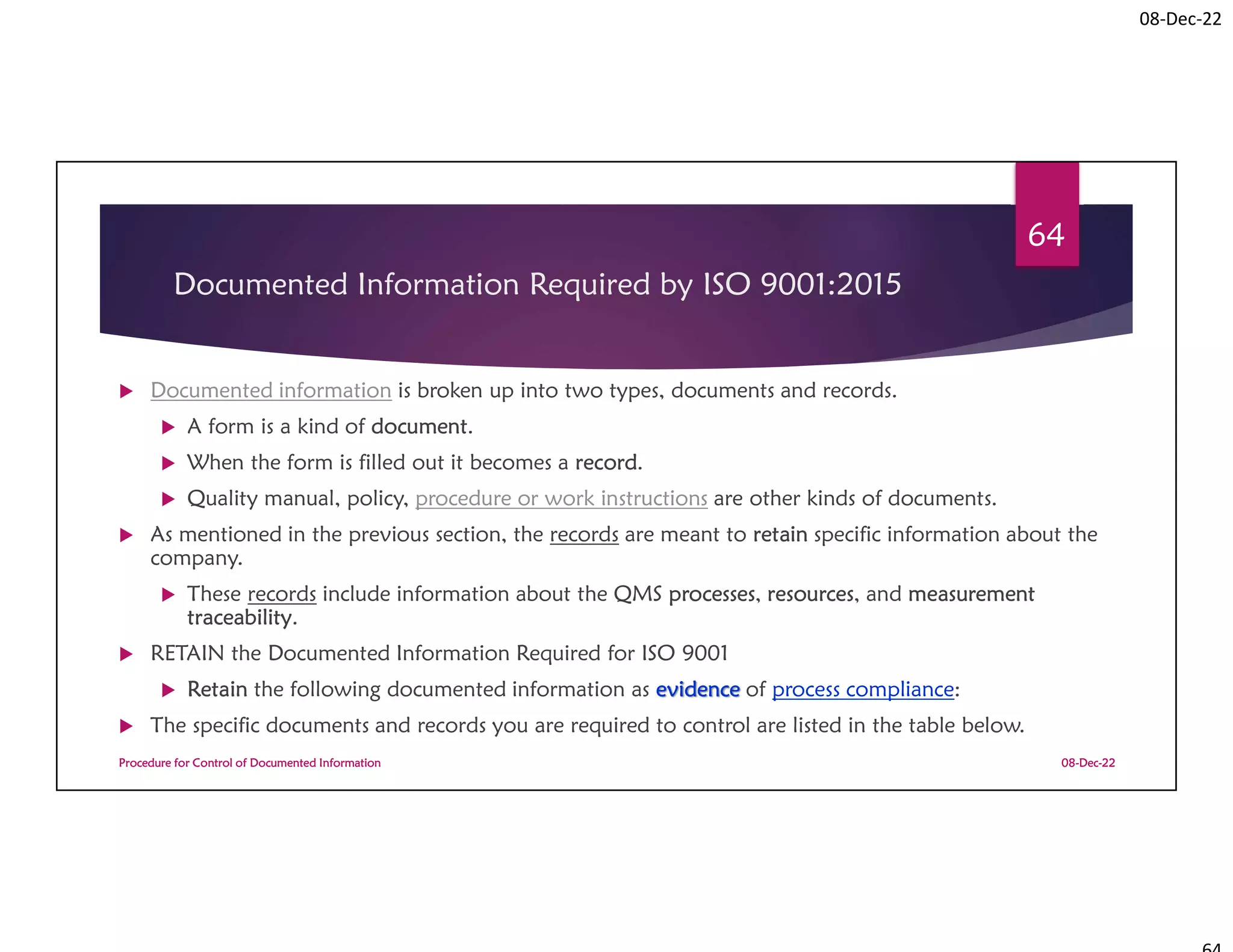

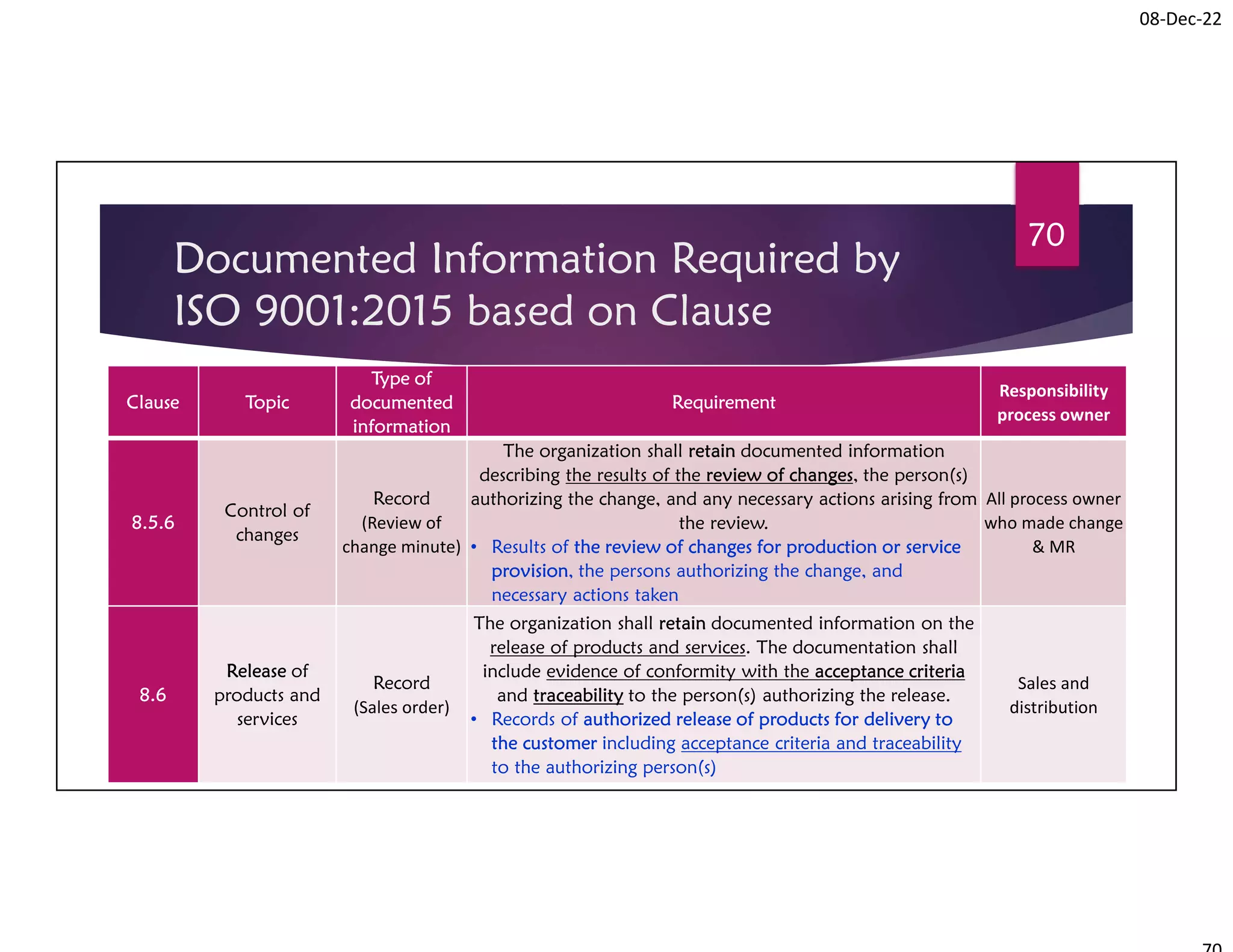

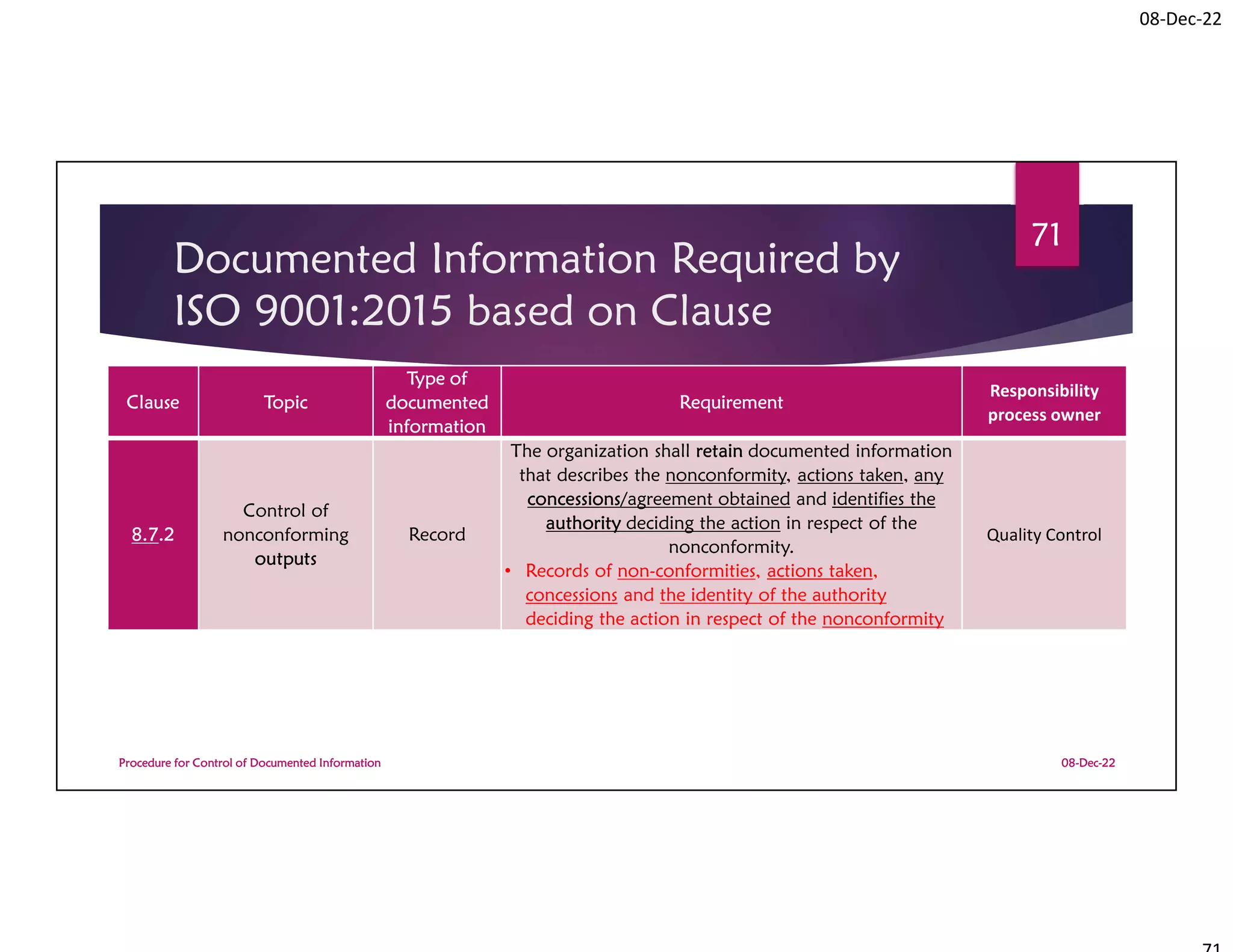

This document summarizes a workshop on ISO 9001:2015 quality management system documentation requirements. The workshop objectives were to improve documentation practices, brief attendees on ISO 9001 clauses and principles, and orient them on procedures for controlling documented information. It covered topics like the importance of documentation, the ISO definition of documented information, and the requirement to maintain control of documents and records. A procedure for controlling documented information was also presented.

![08-Dec-22

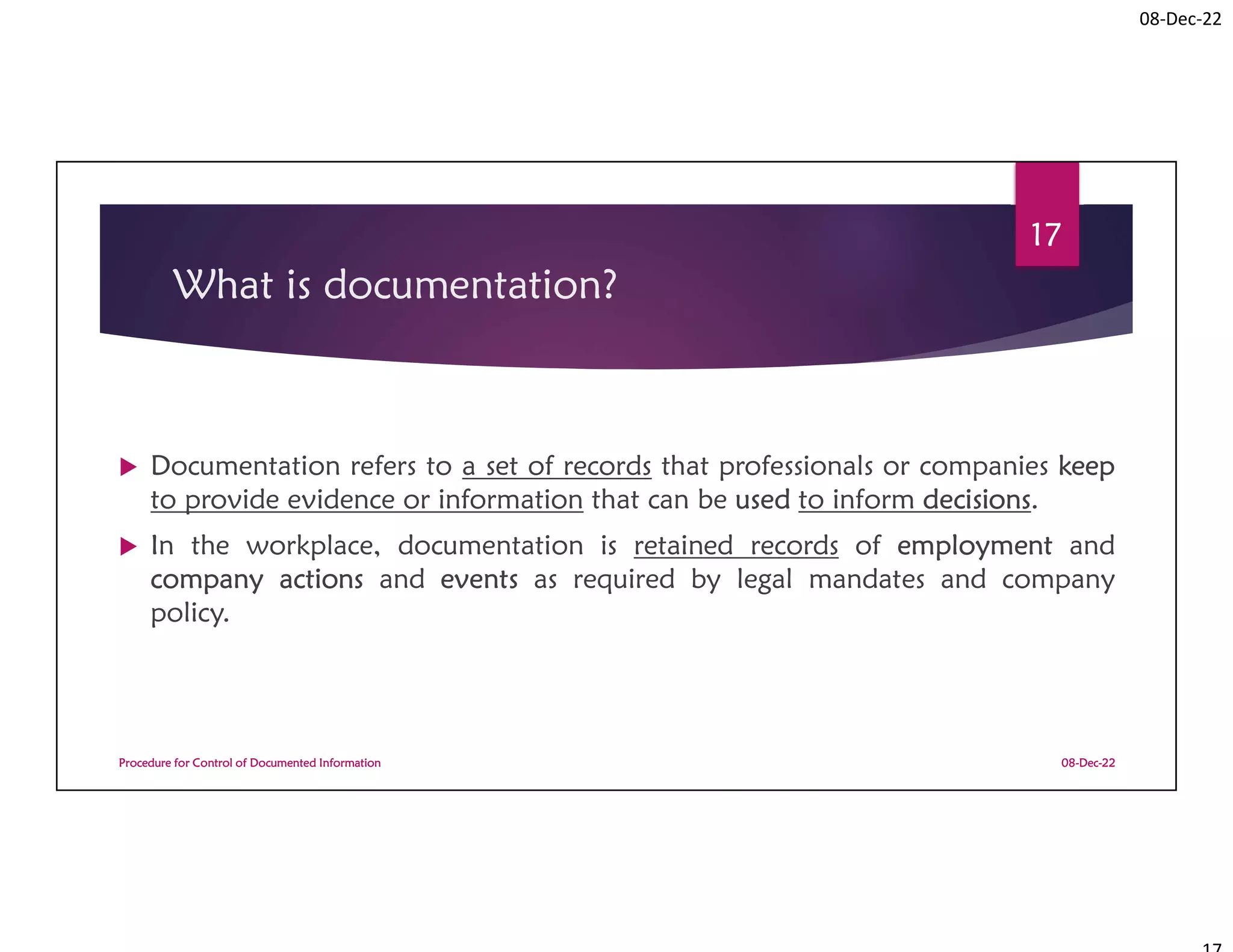

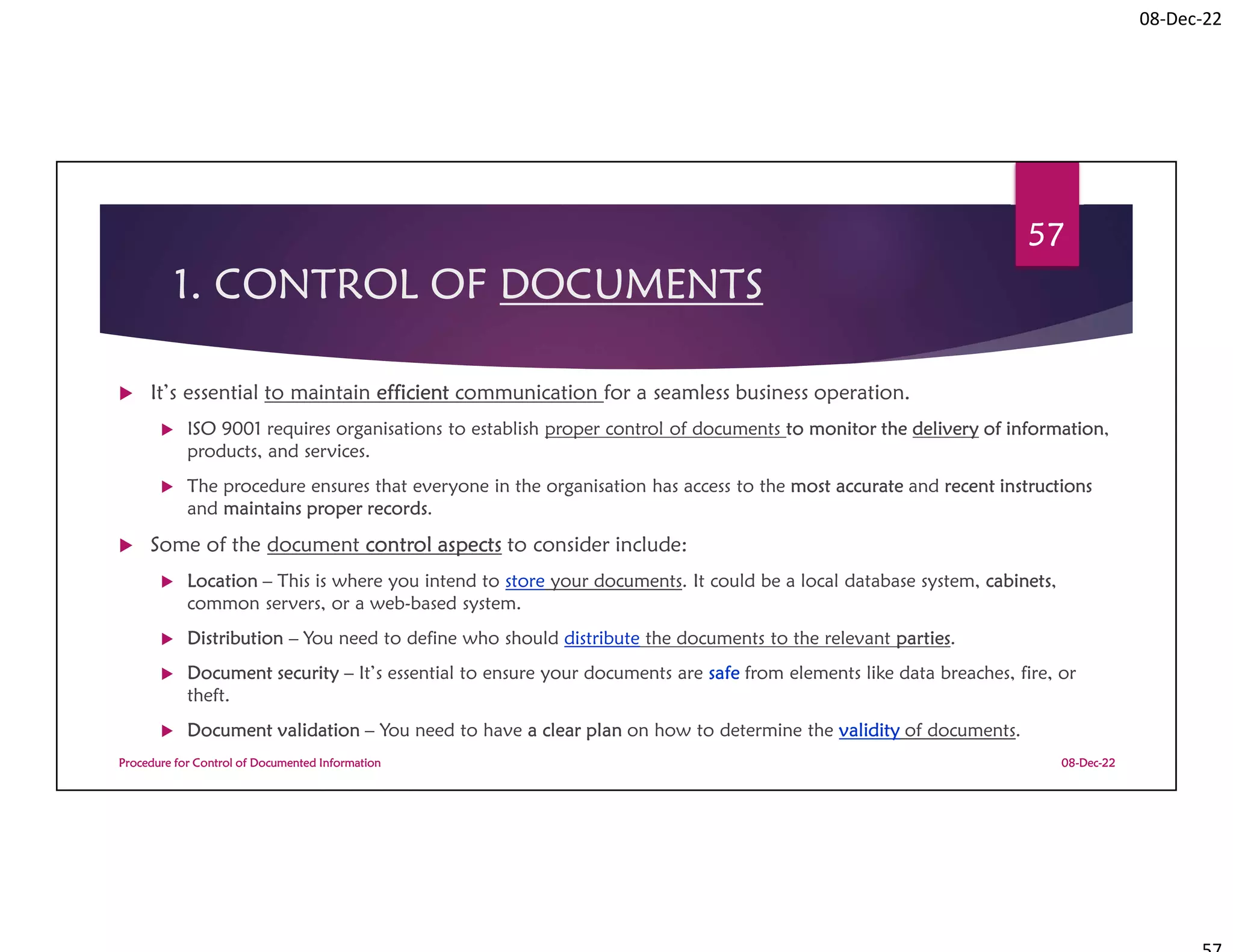

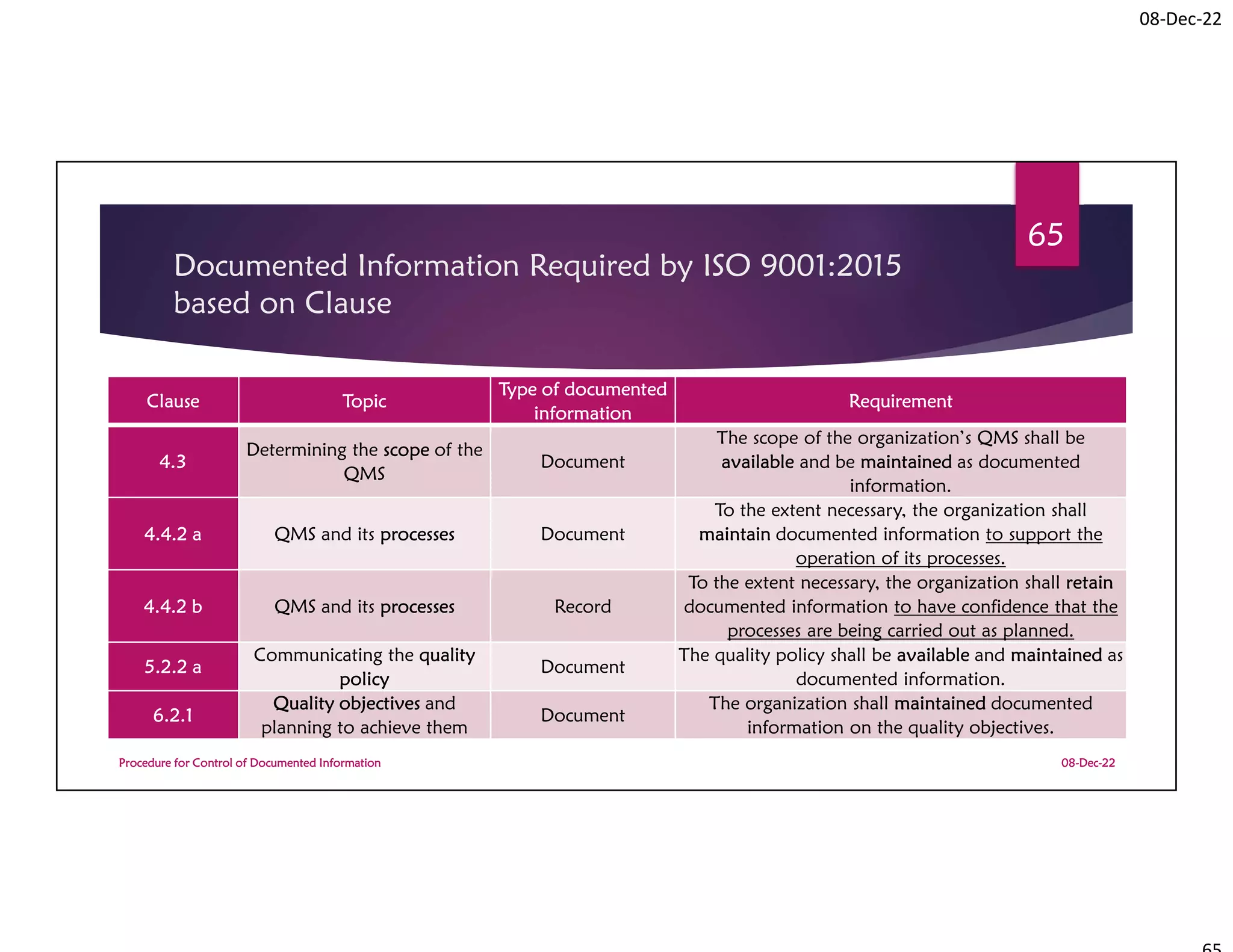

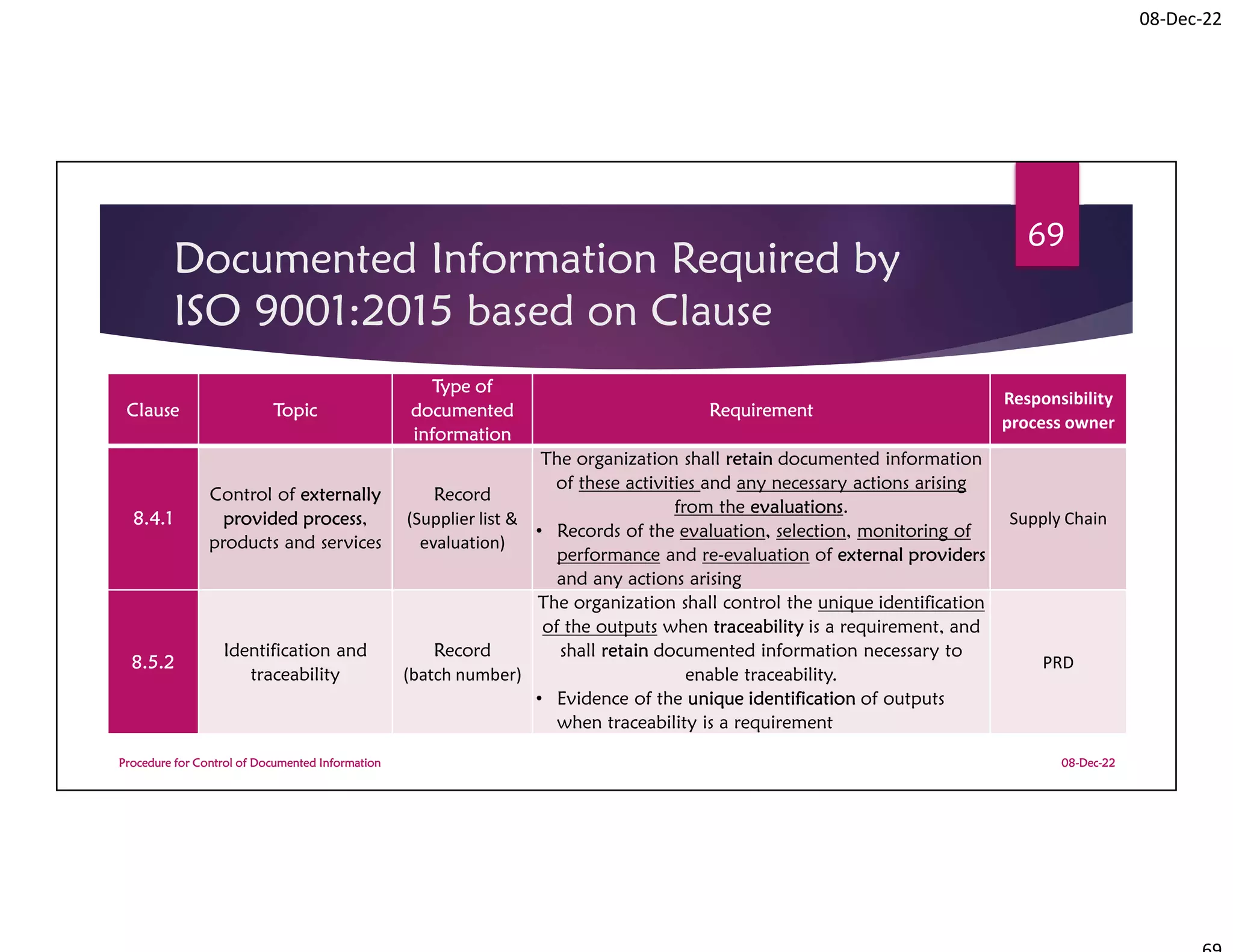

Documented Information Required by

ISO 9001:2015 based on Clause

08-Dec-22

Procedure for Control of Documented Information

72

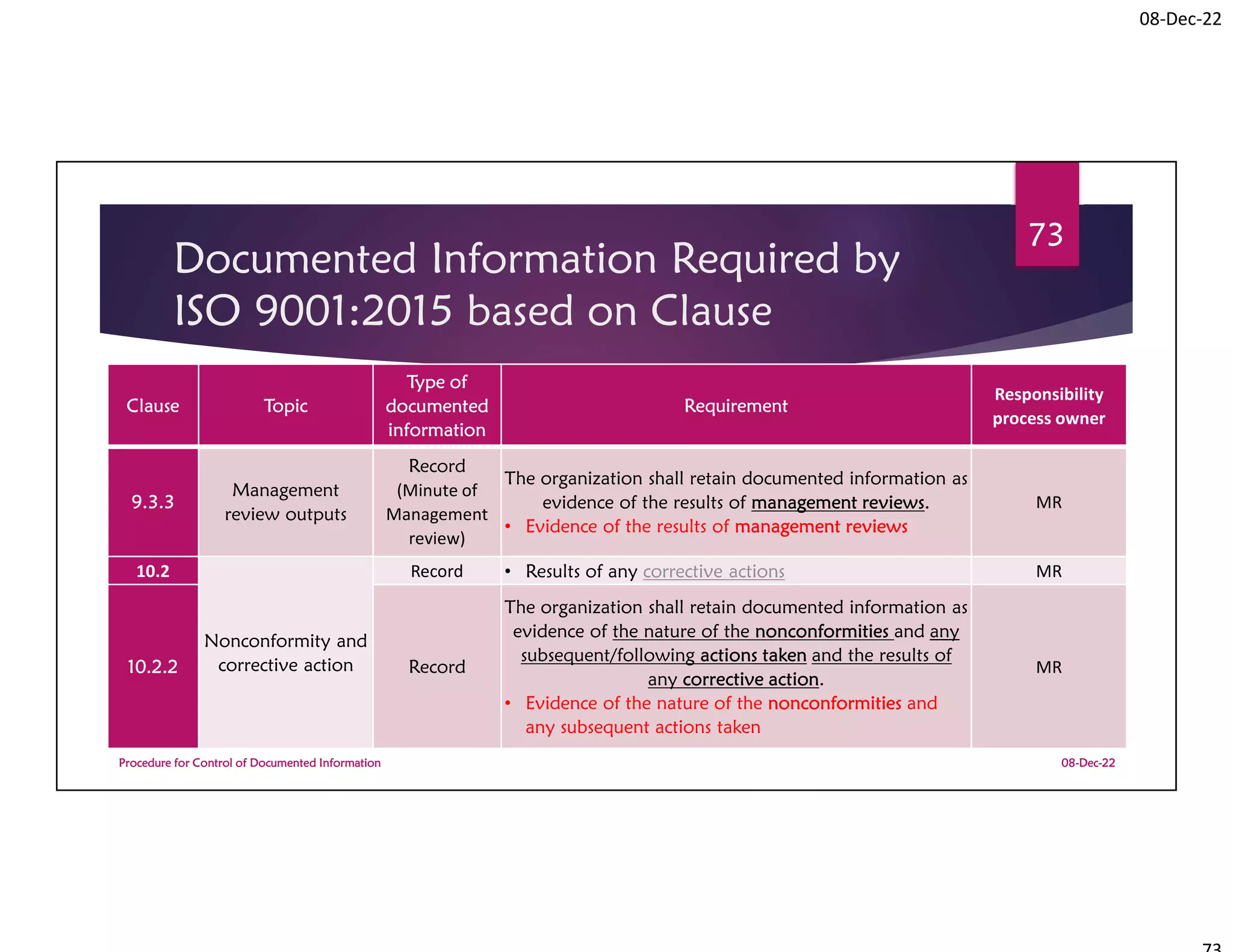

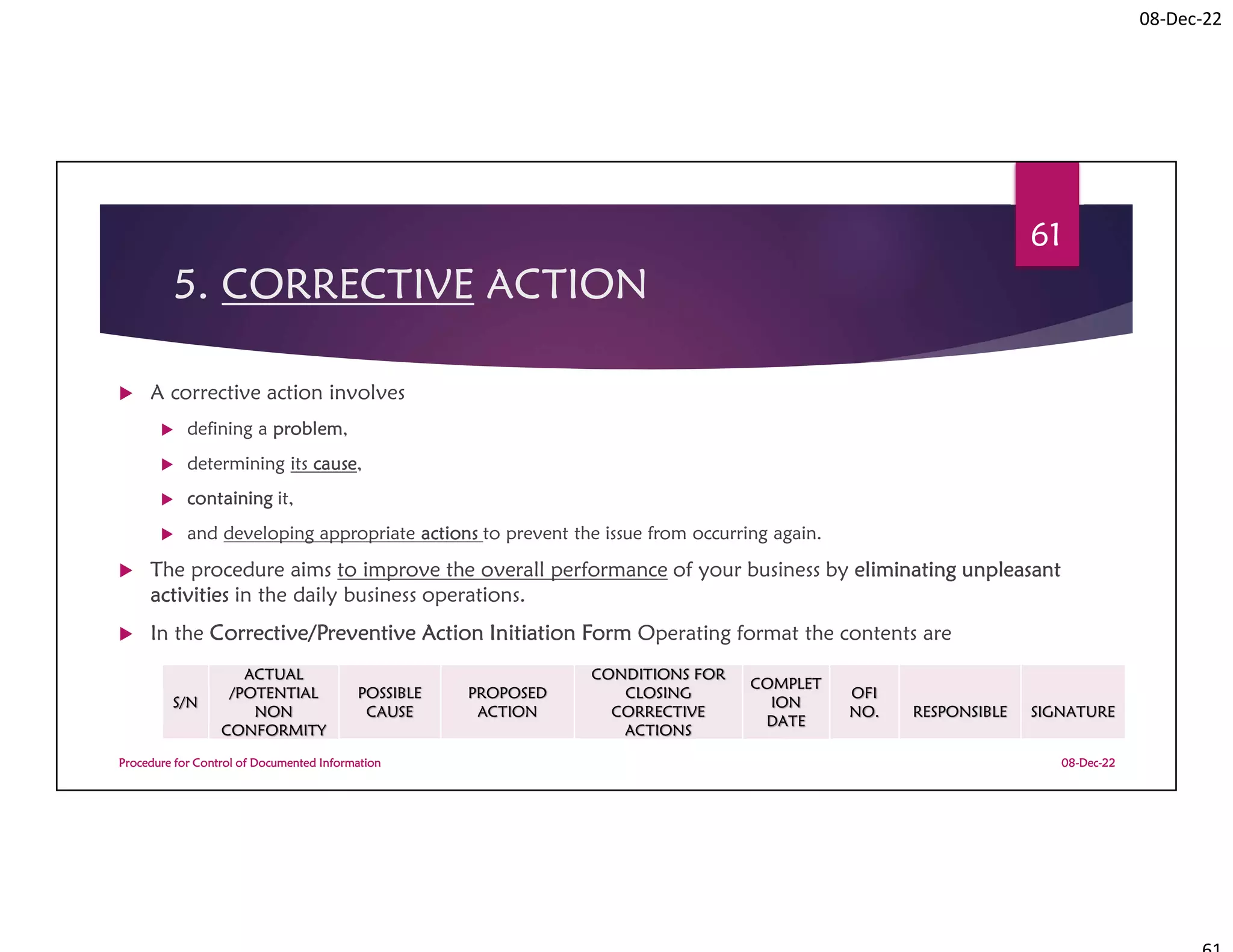

Clause Topic

Type of

documented

information

Requirement

Responsibility

process owner

9.1.1

Monitoring,

measurement,

analysis and

evaluation

Record

(monthly and

annual

performance

report)

The organization shall retain documented information as

evidence of the results [of QMS performance

evaluation].

• Results of the evaluation of the performance and the

effectiveness of the QMS

All operational

report

9.2.2 f Internal audit

Record

(internal audit

program &

report)

The organization shall retain documented information as

evidence of the implementation of the audit program

and the audit results.

• Evidence of the implementation of the audit

programme and the audit results

MR](https://image.slidesharecdn.com/procedureforcontrolofdocumentedinformationfortraniee1-230416173233-17e63101/75/Procedure-for-control-of-Documented-Information-for-traniee-1-pdf-72-2048.jpg)