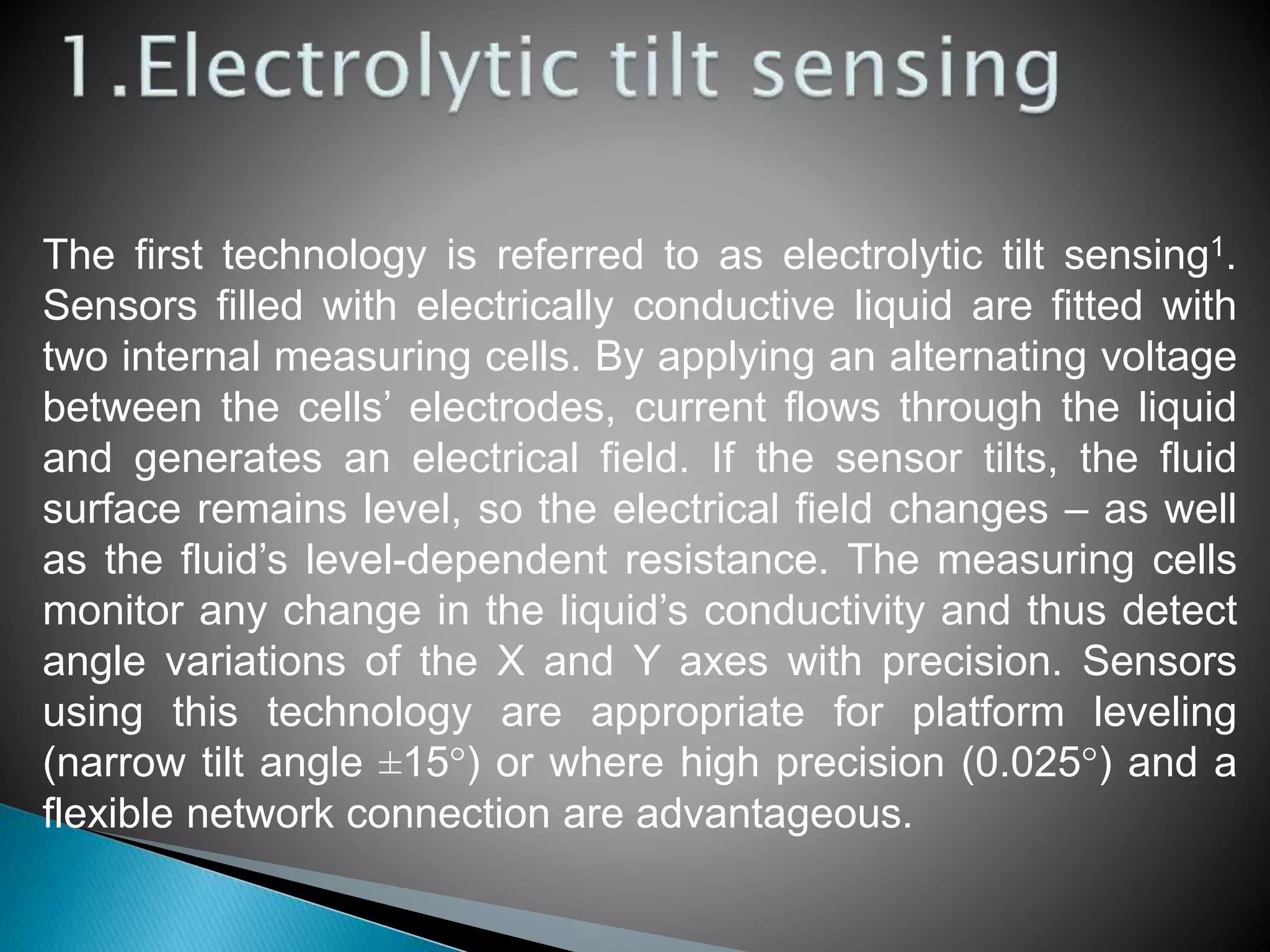

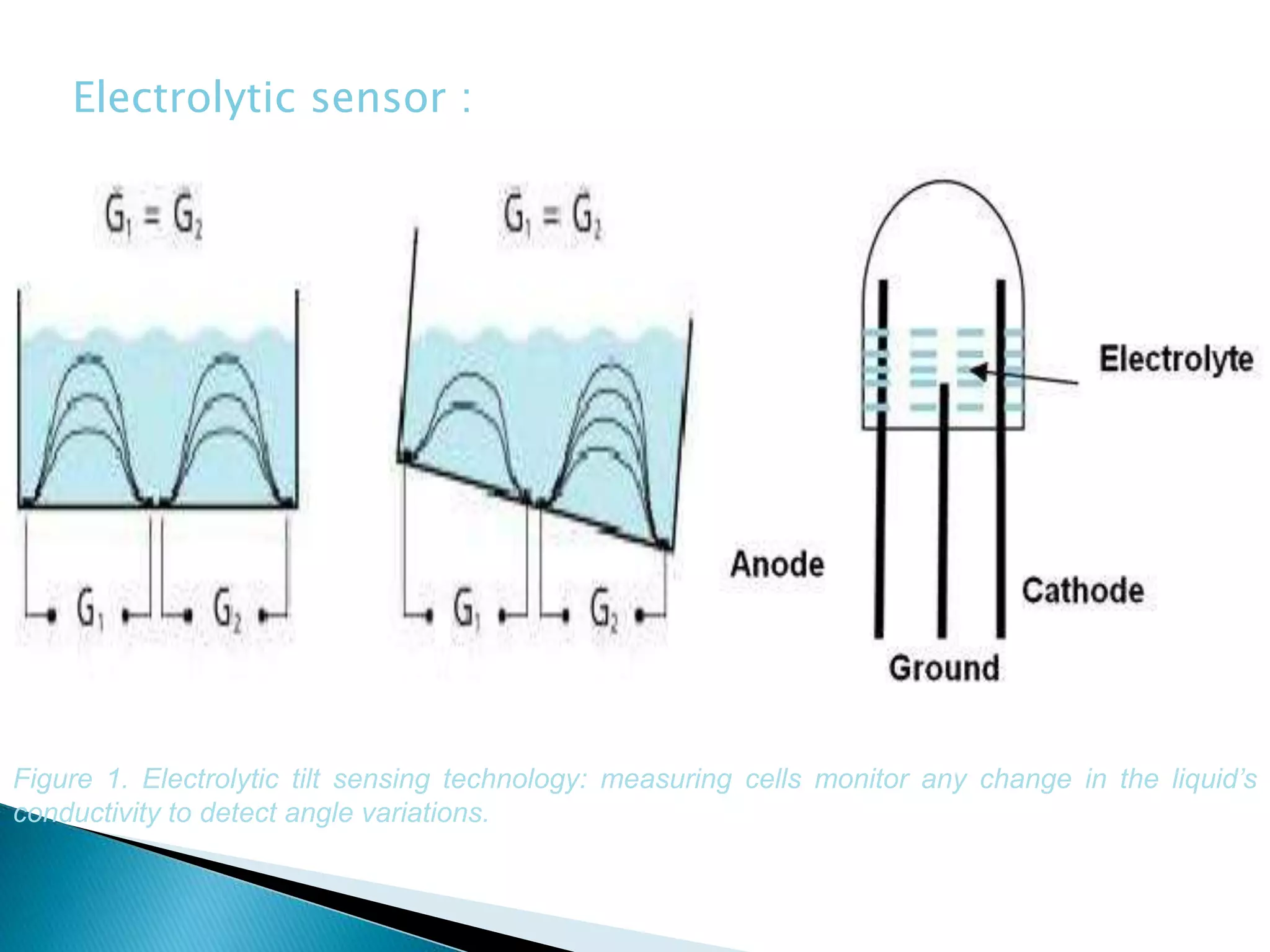

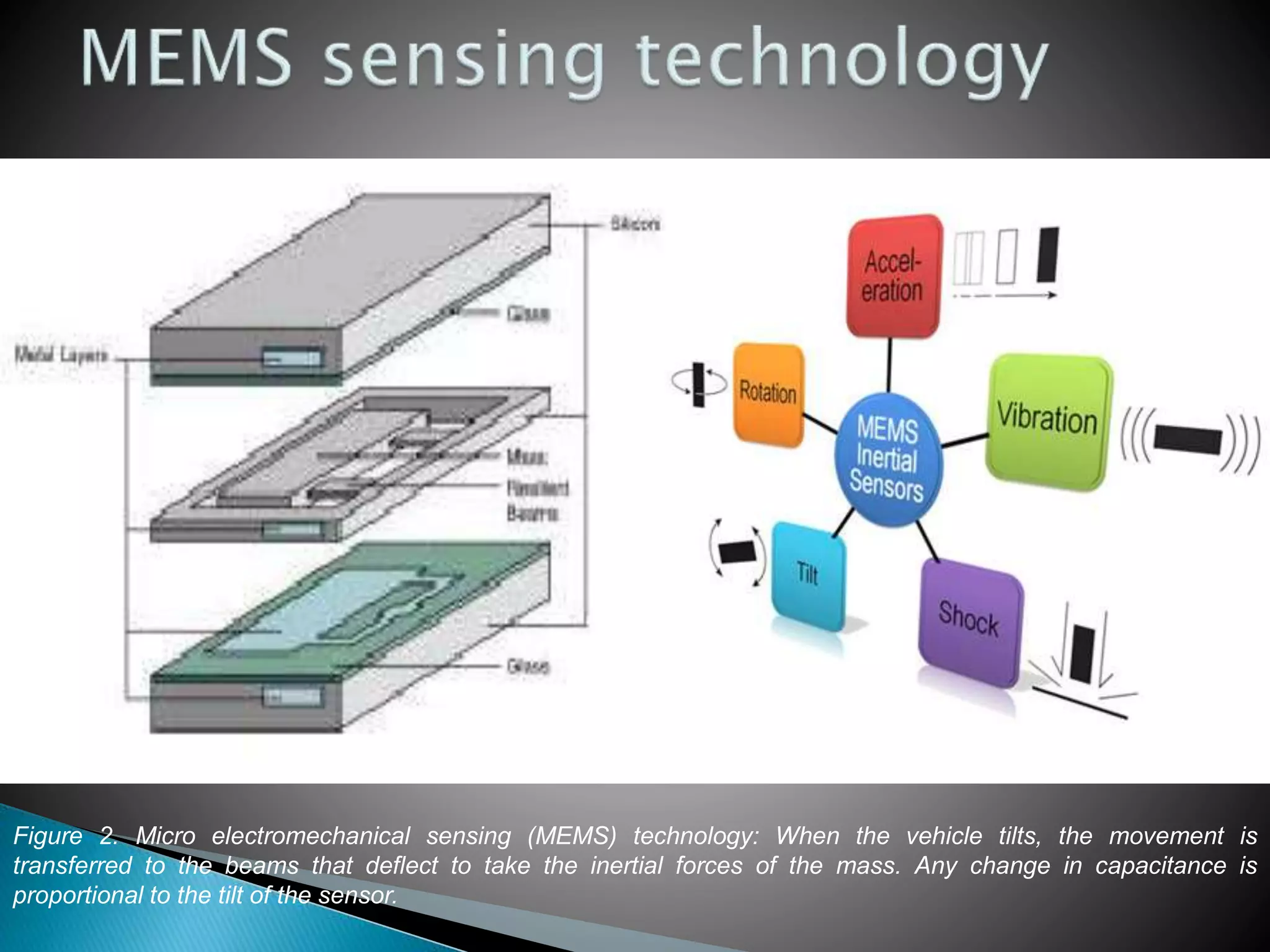

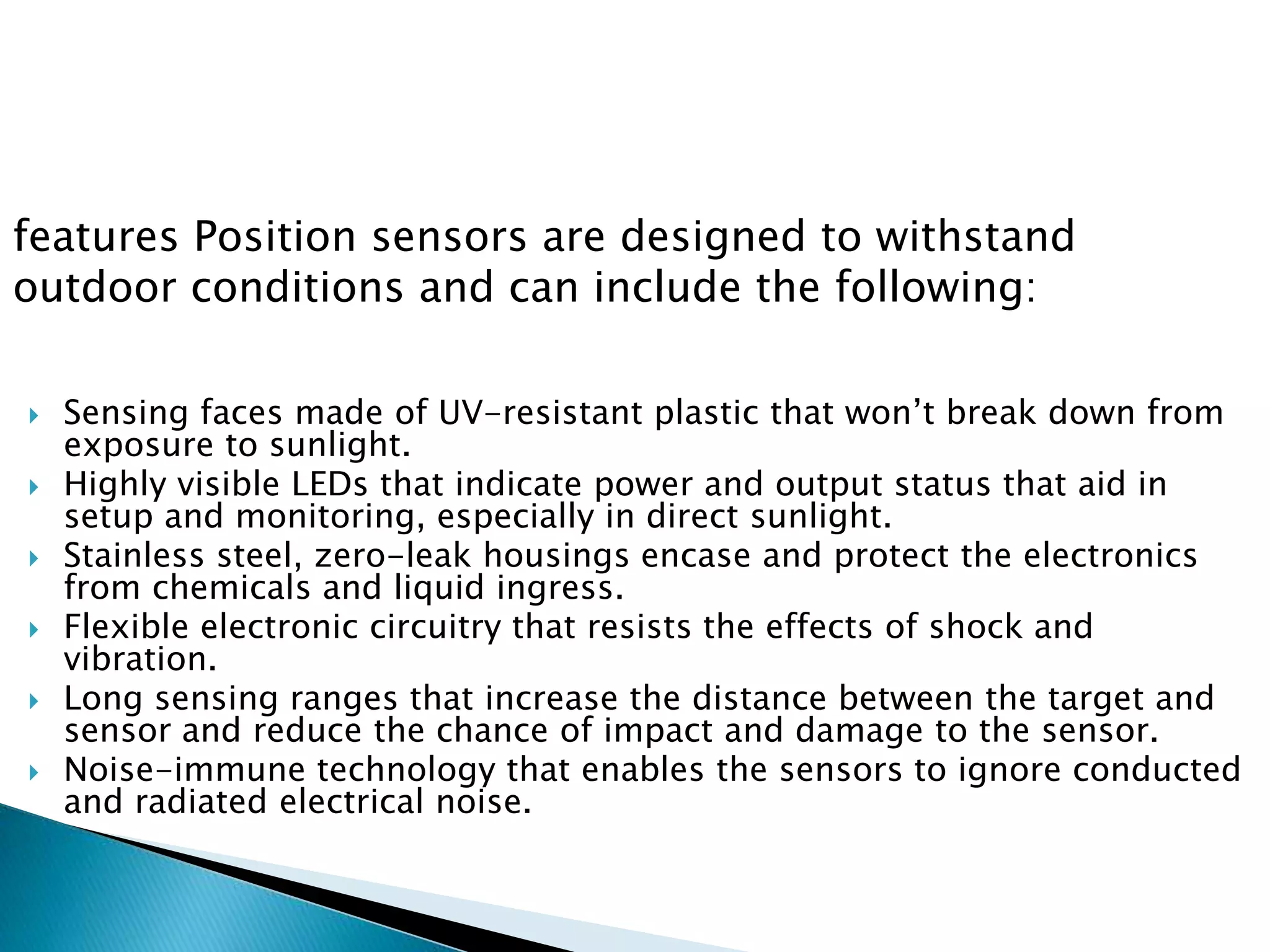

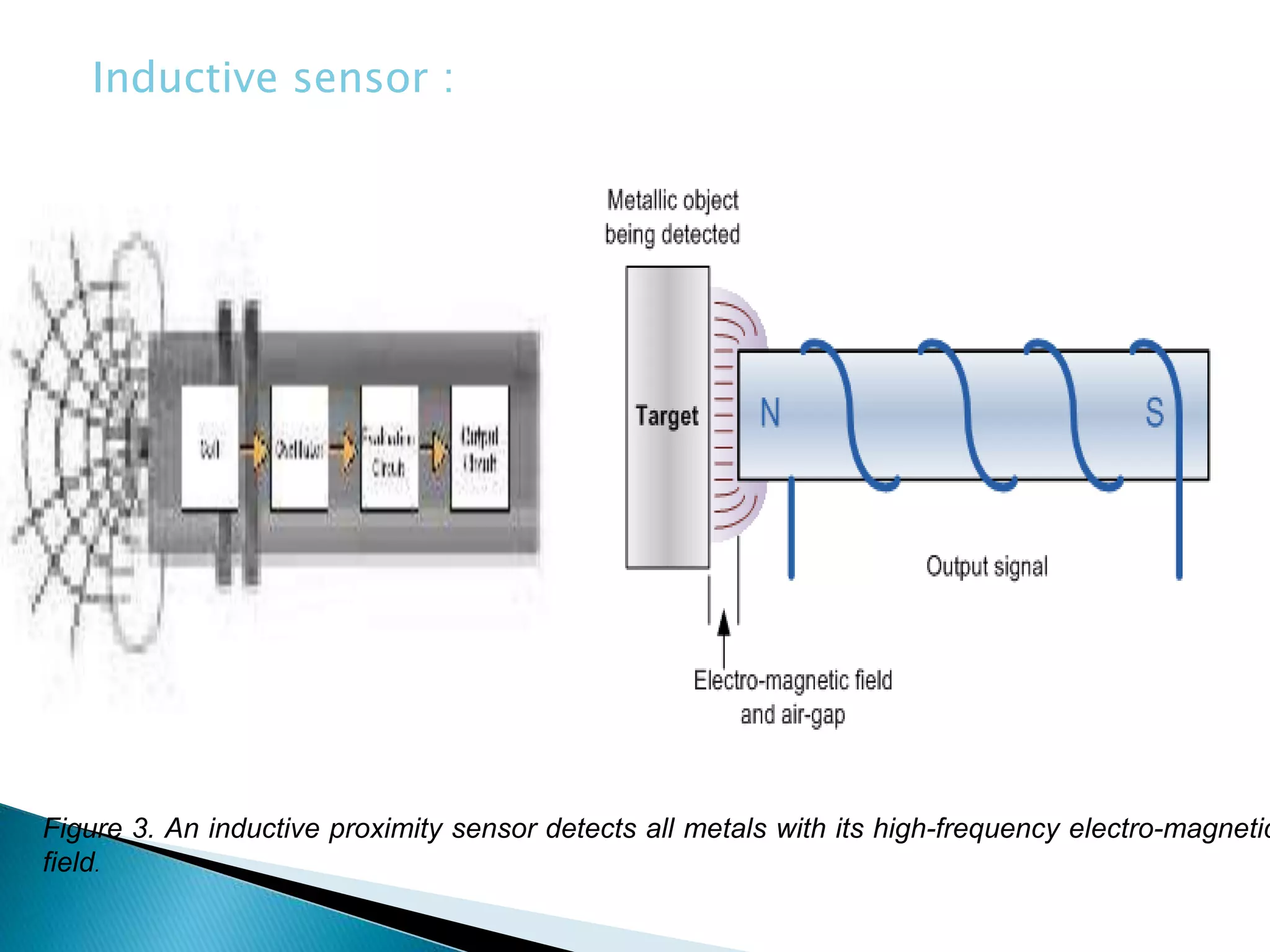

Electronic sensors can improve safety for operators of off-road vehicles by monitoring the vehicle's operating conditions and alignment. This document discusses three types of sensors that can be used: tilt sensors detect the vehicle's horizontal alignment, inductive position sensors monitor the position of moving parts, and pressure sensors check the hydraulic system. Each sensor type is exposed to harsh environmental conditions but can help warn operators if the vehicle or its load is at risk.