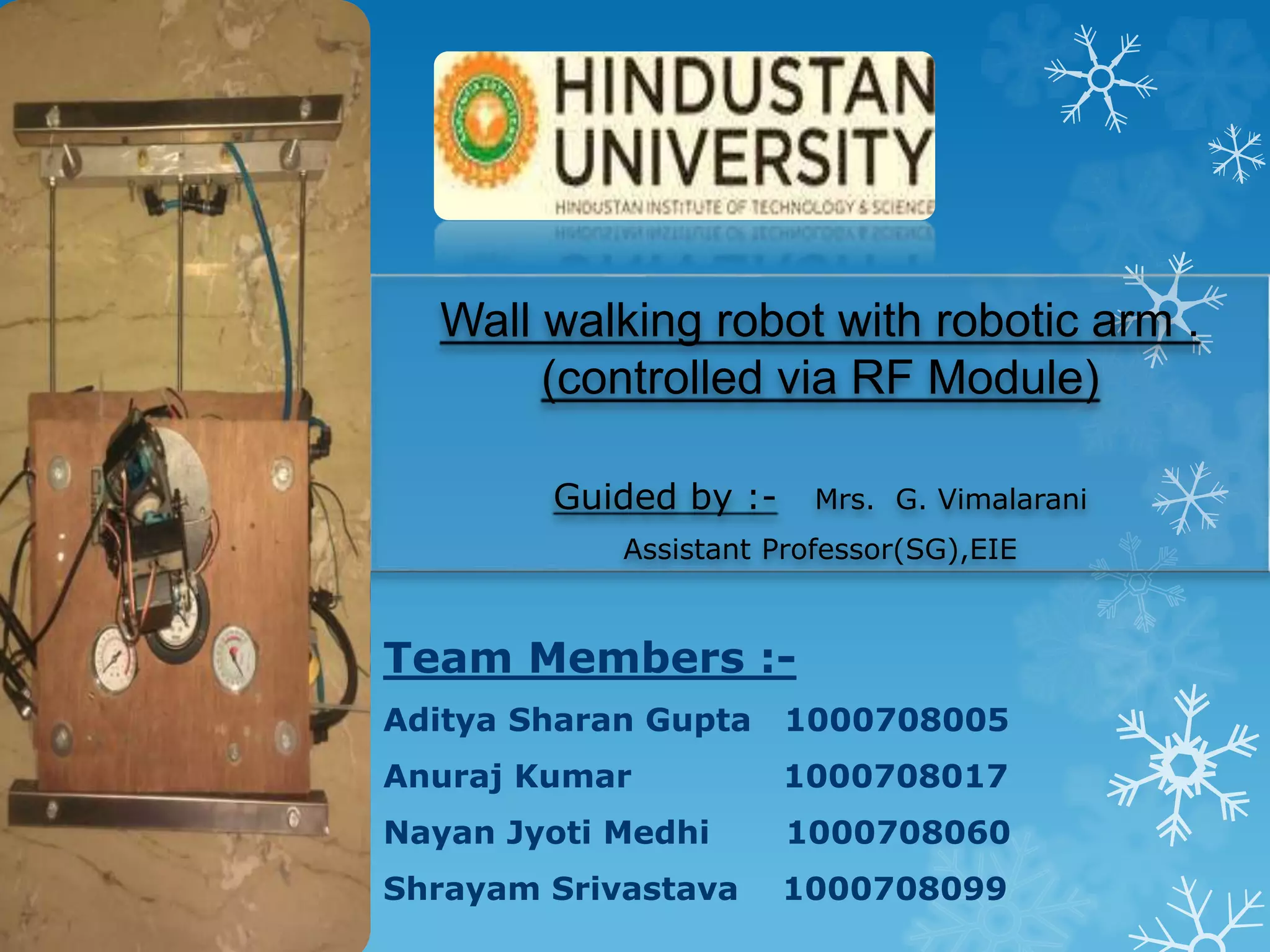

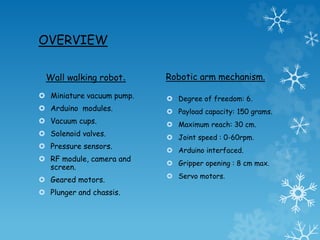

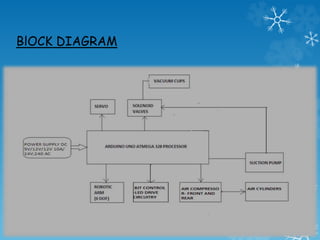

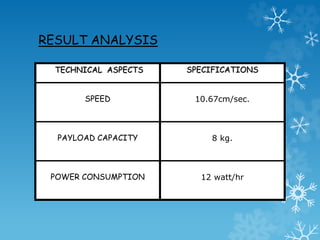

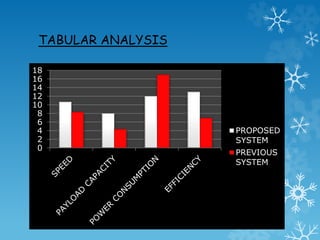

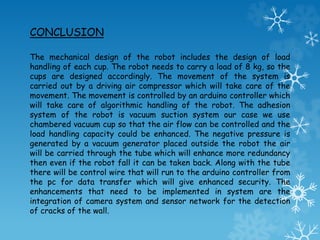

The document summarizes the design and development of a multifunctional wall walking robot with a robotic arm. The robot is designed to be stable, flexible, and able to work in hazardous environments through monitoring or military applications. It uses vacuum adhesion for movement and is controlled wirelessly via an RF module and Arduino controller. The robotic arm has 6 degrees of freedom and can lift payloads of up to 150g with a reach of 30cm. The design aims to improve on previous models by reducing costs, size, and complexity while increasing the working area and capabilities. It was tested to have a speed of 10.67cm/s, payload capacity of 8kg, and power consumption of 12W/hr.