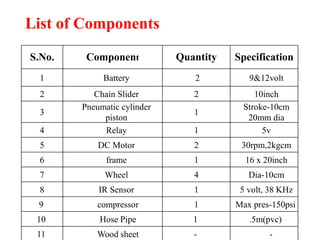

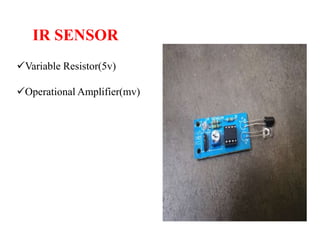

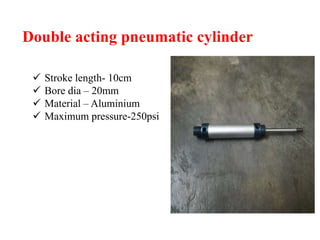

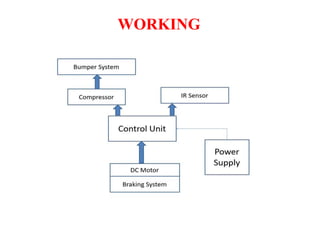

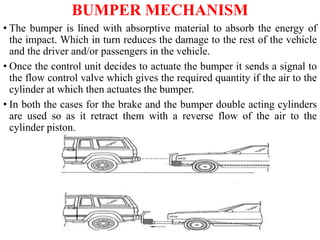

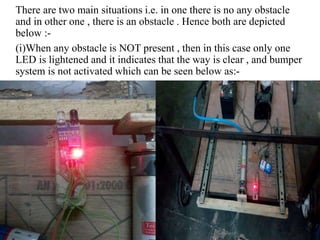

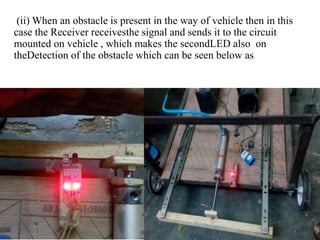

The document presents a project on an automatic pneumatic bumper and braking system aimed at preventing vehicle collisions by utilizing sensors to detect proximity to other vehicles. It outlines the components involved, the working principle of the system, advantages over traditional airbags, and potential future enhancements. The conclusion emphasizes the system's role in increasing safety for passengers and vehicles, thereby reducing the likelihood and impact of road accidents.