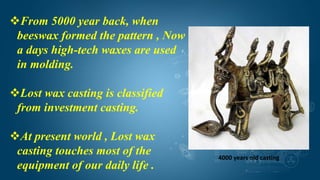

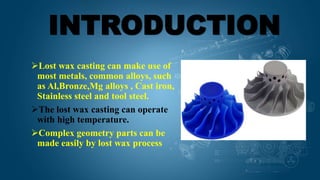

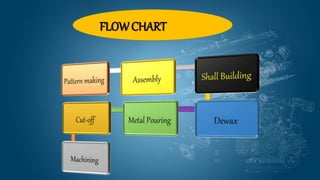

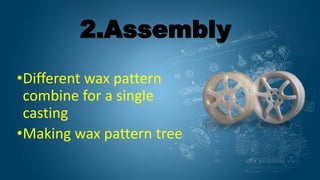

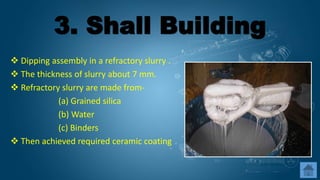

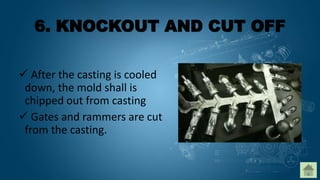

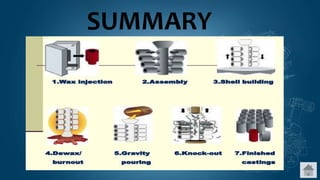

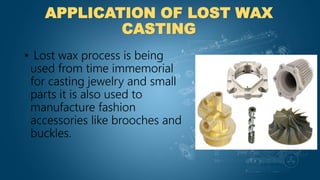

The presentation on lost wax casting outlines the historical background, manufacturing procedure, advantages, disadvantages, and applications of this ancient casting technique. It details the process of creating intricate designs and components using wax patterns, emphasizing its use in jewelry, dental restorations, and automotive parts. Despite its benefits in producing high-quality, precise castings, lost wax casting is limited by high costs and long production cycles, making it less suitable for large-scale manufacturing.