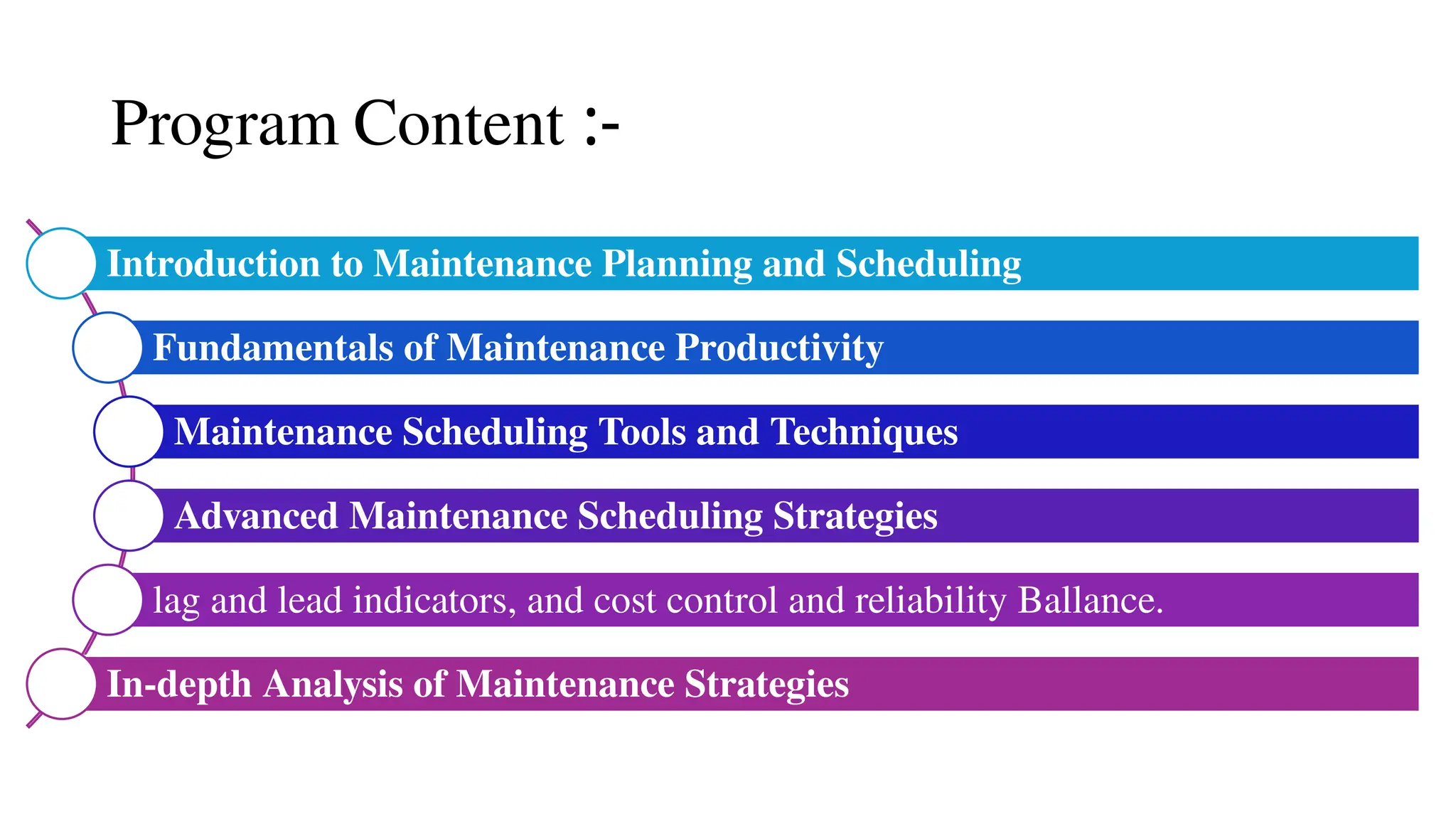

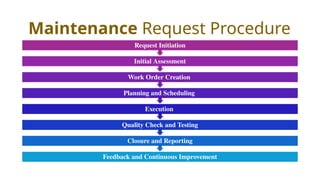

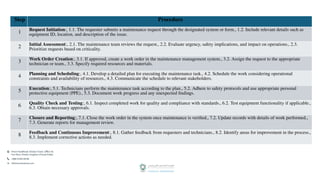

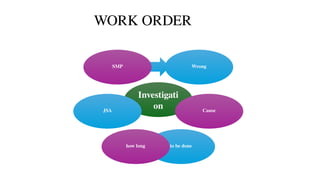

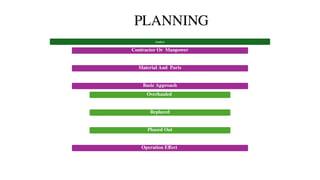

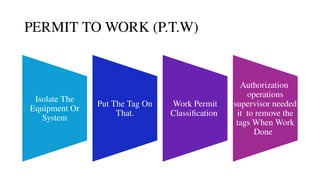

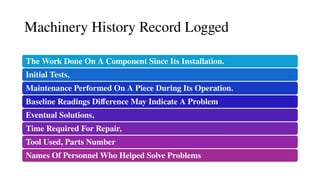

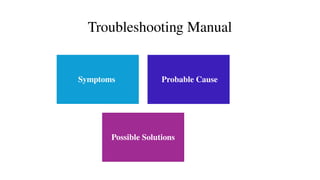

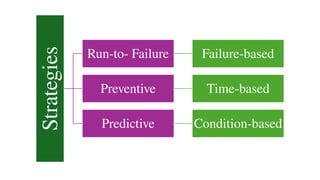

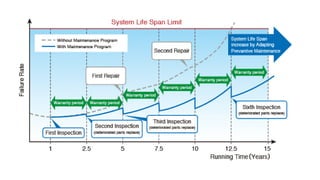

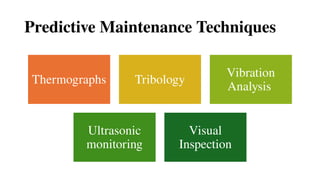

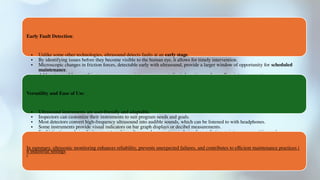

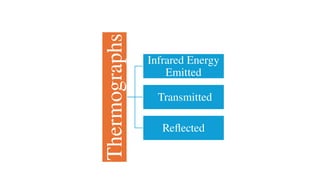

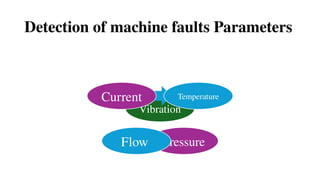

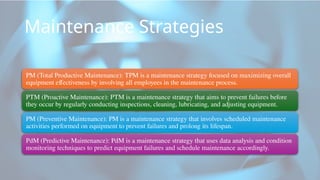

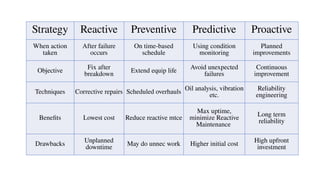

The document outlines key principles of maintenance planning and scheduling, focusing on enhancing maintenance productivity through various tools and techniques. It details the steps of a maintenance request procedure, including initial assessment, work order creation, planning, execution, quality checks, and closure. Additionally, it discusses diverse maintenance strategies, such as proactive, preventive, and predictive maintenance, highlighting the importance of condition monitoring and feedback for continuous improvement.