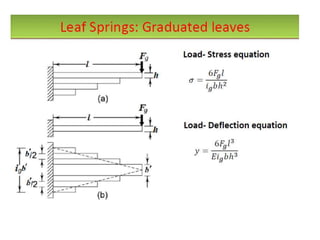

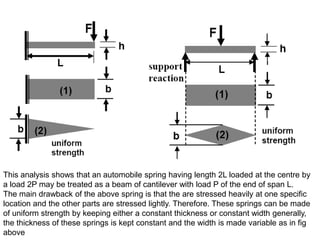

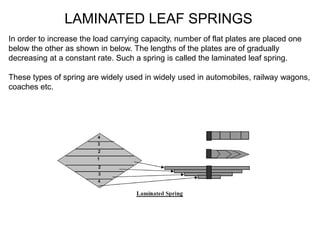

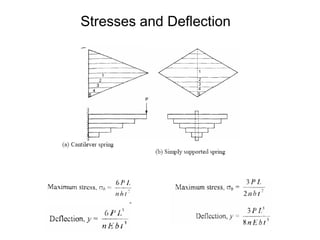

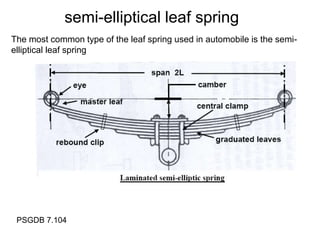

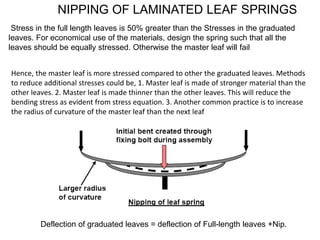

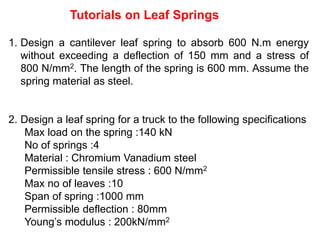

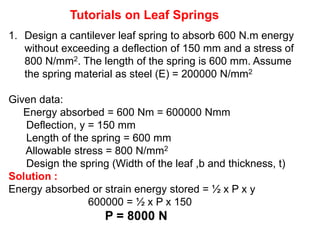

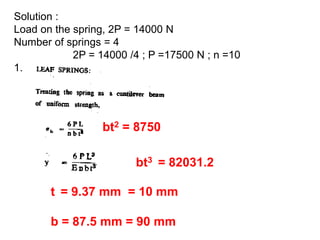

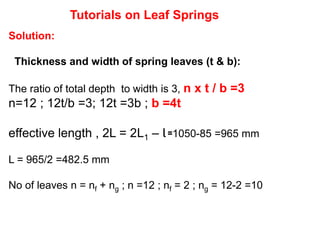

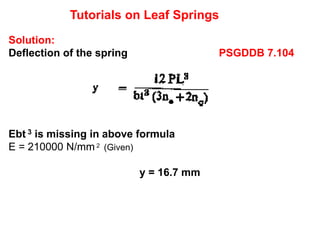

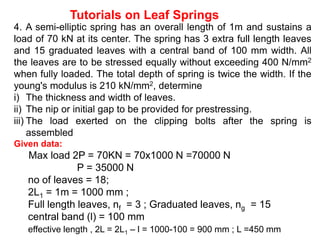

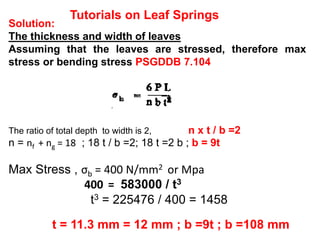

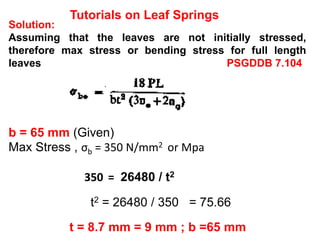

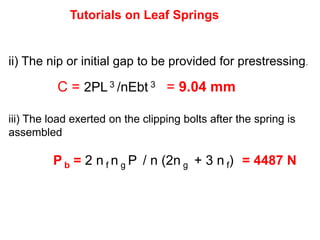

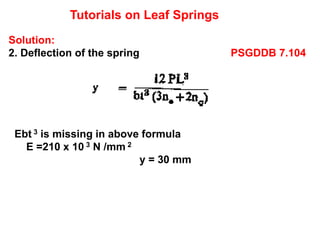

This document discusses leaf springs used in automobiles and other vehicles. It provides information on simply supported and cantilever beams which can be used as leaf springs to absorb energy under load. Leaf springs can act as both structural members and energy absorbing devices. Laminated leaf springs are discussed, which use multiple flat plates stacked to increase load capacity. Formulas are provided for stresses, deflections, and the design of leaf springs. Examples are given for designing leaf springs to meet specified load and stress criteria.