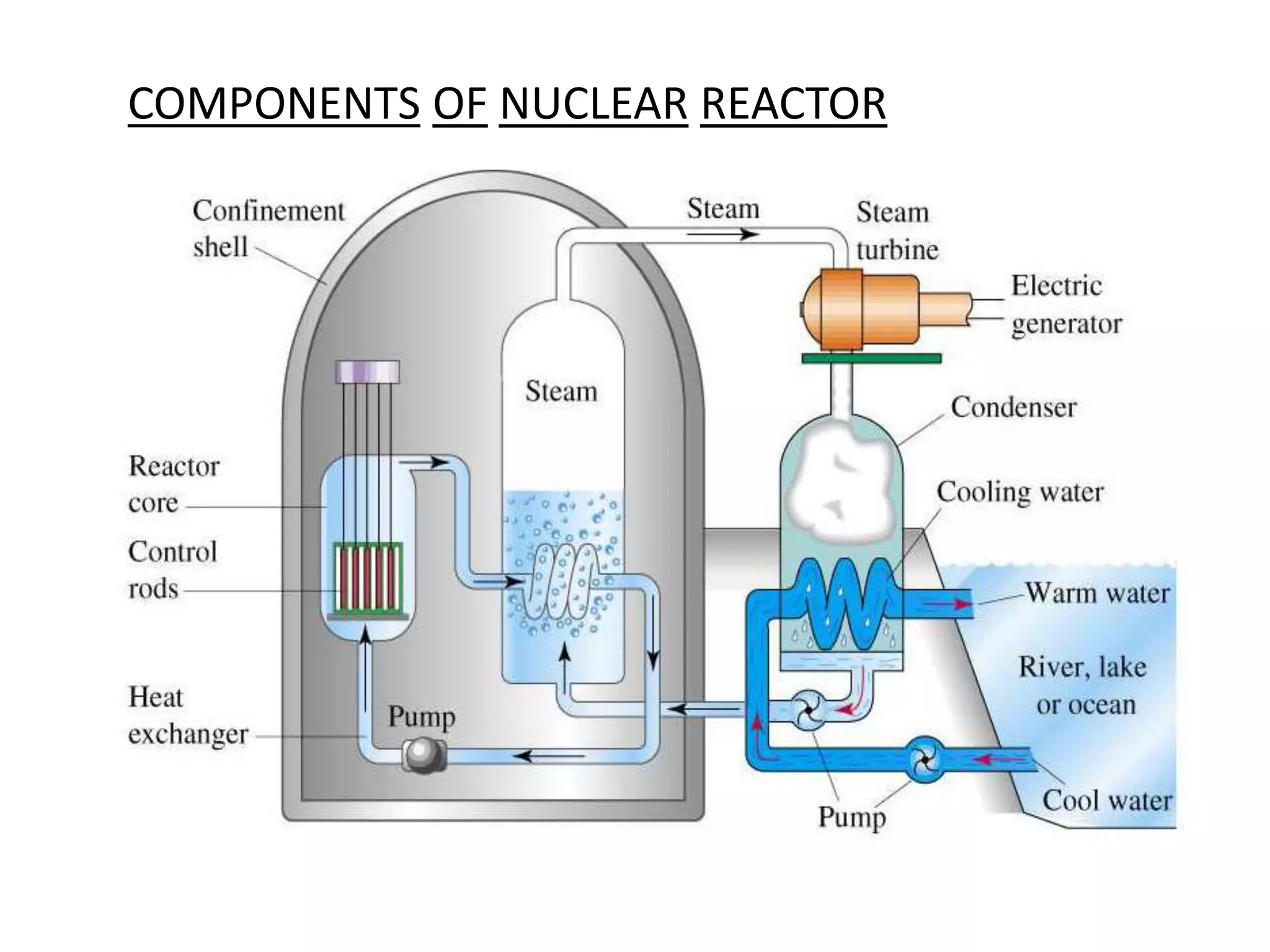

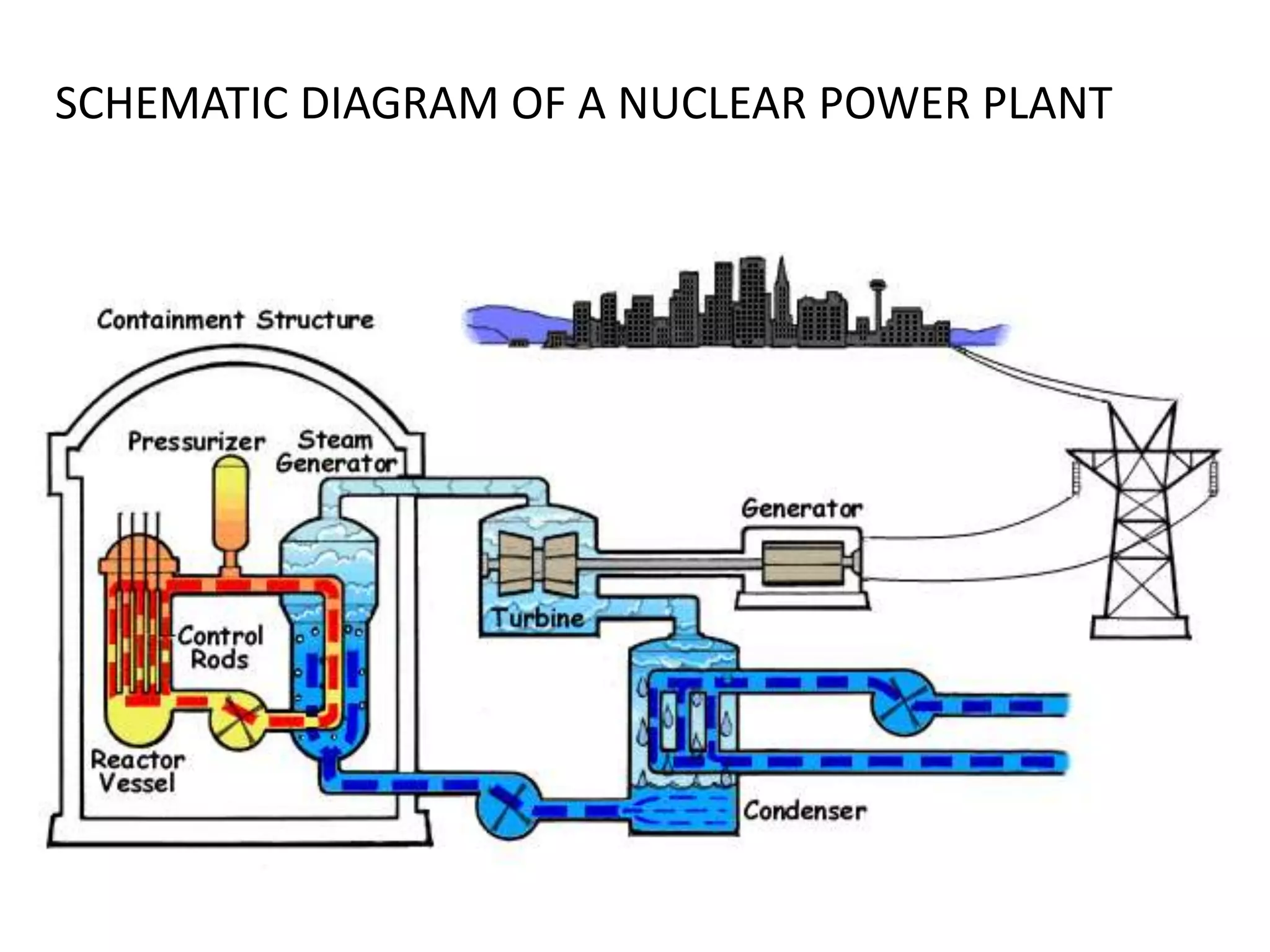

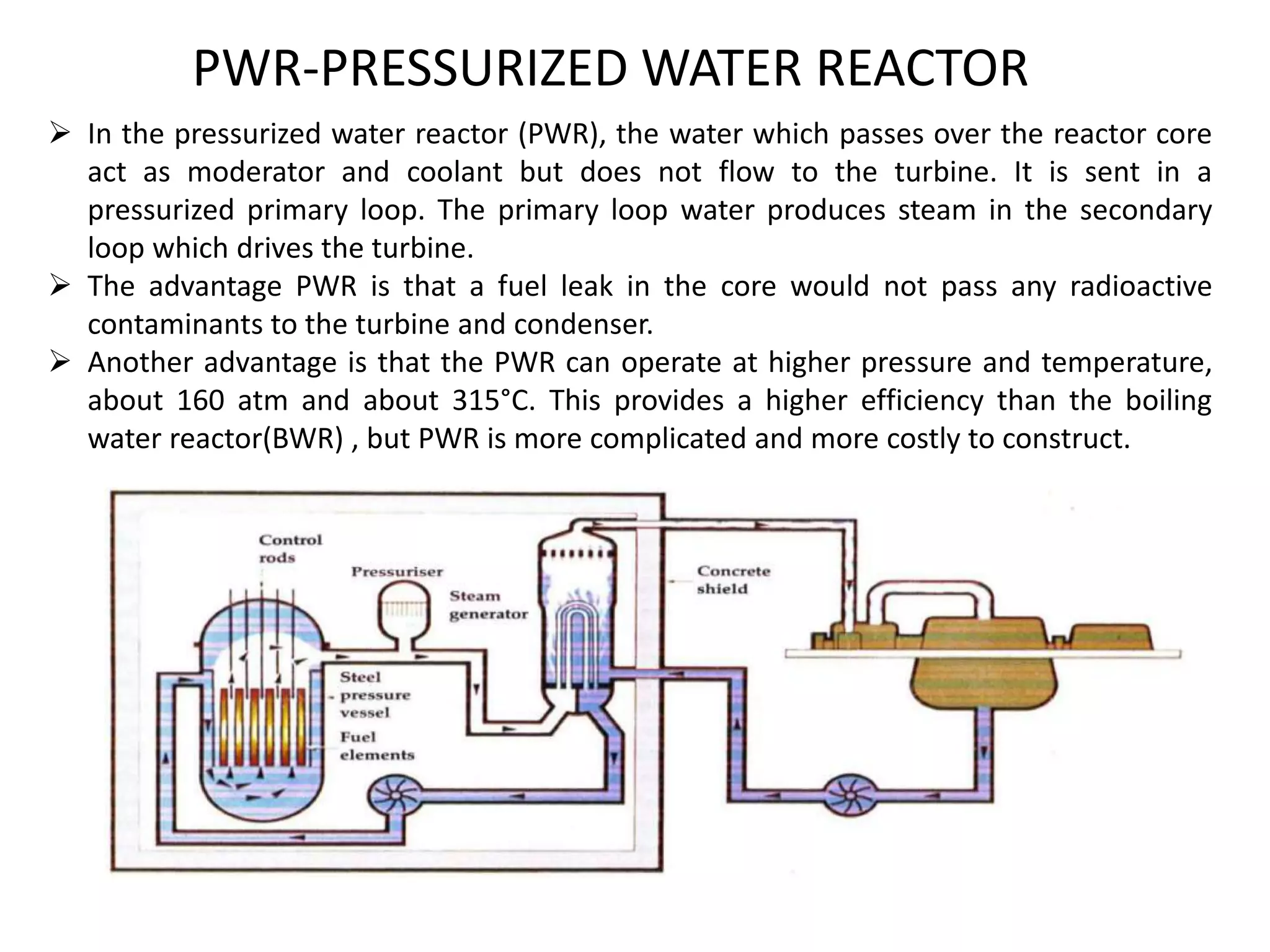

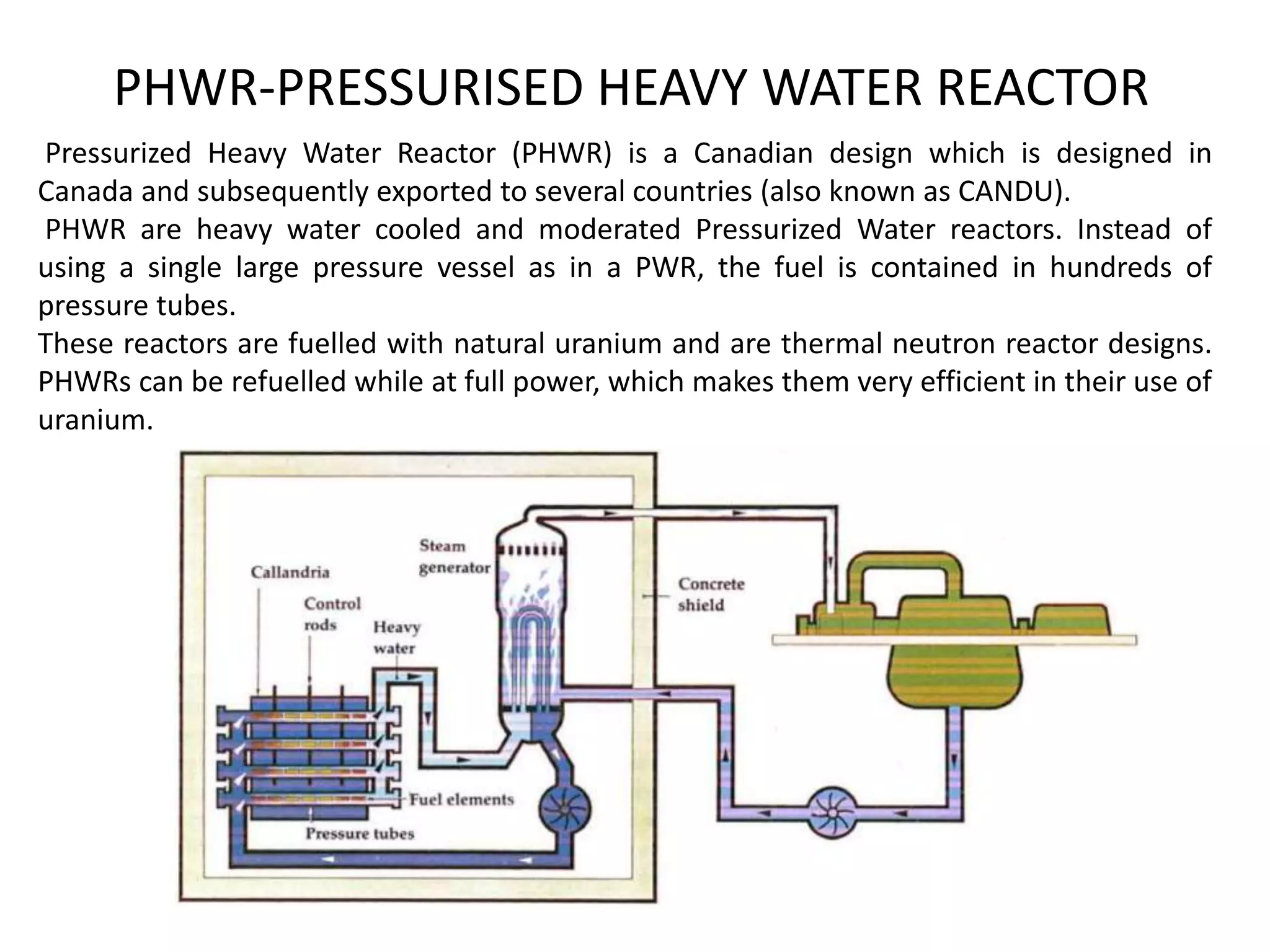

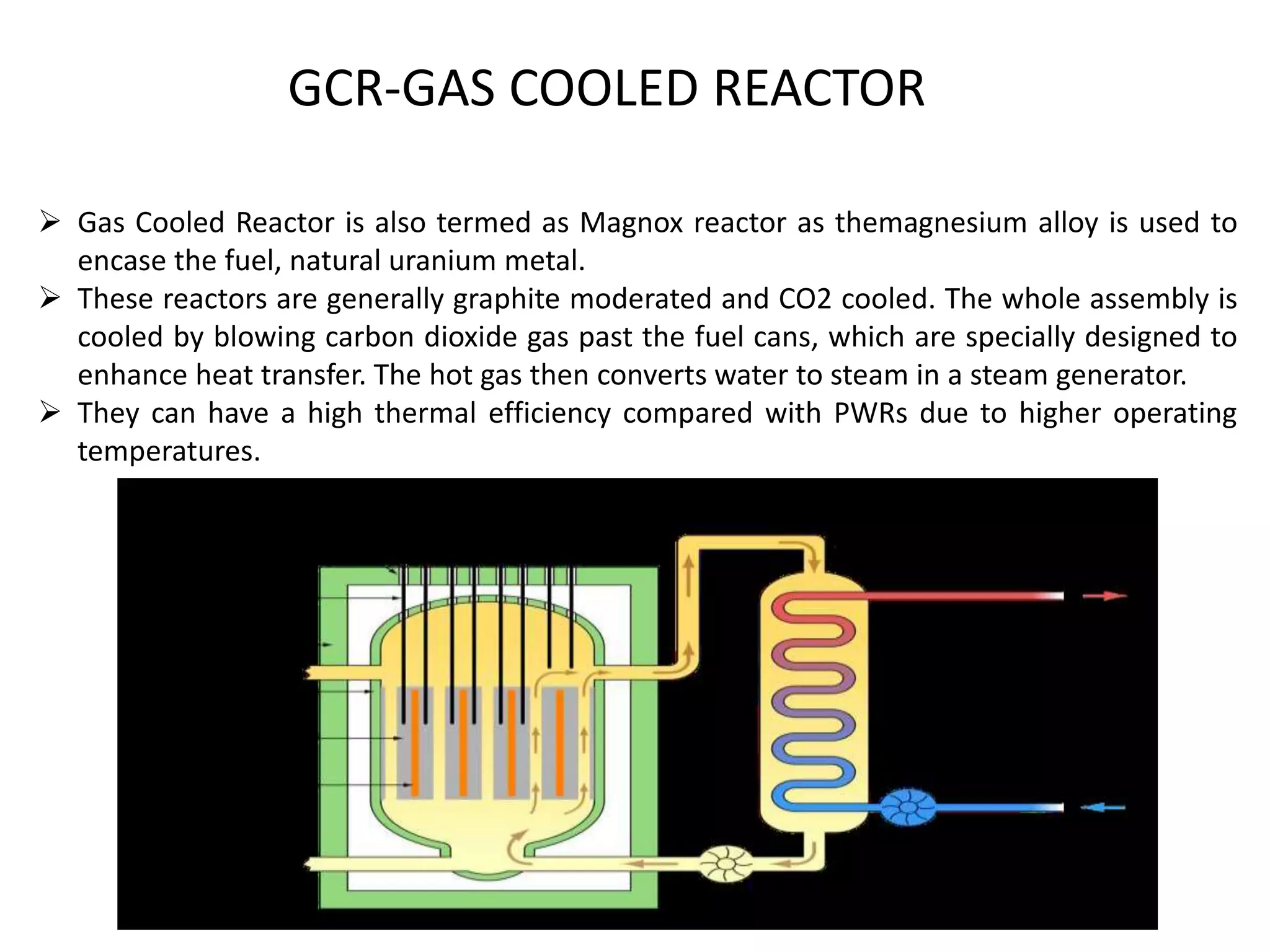

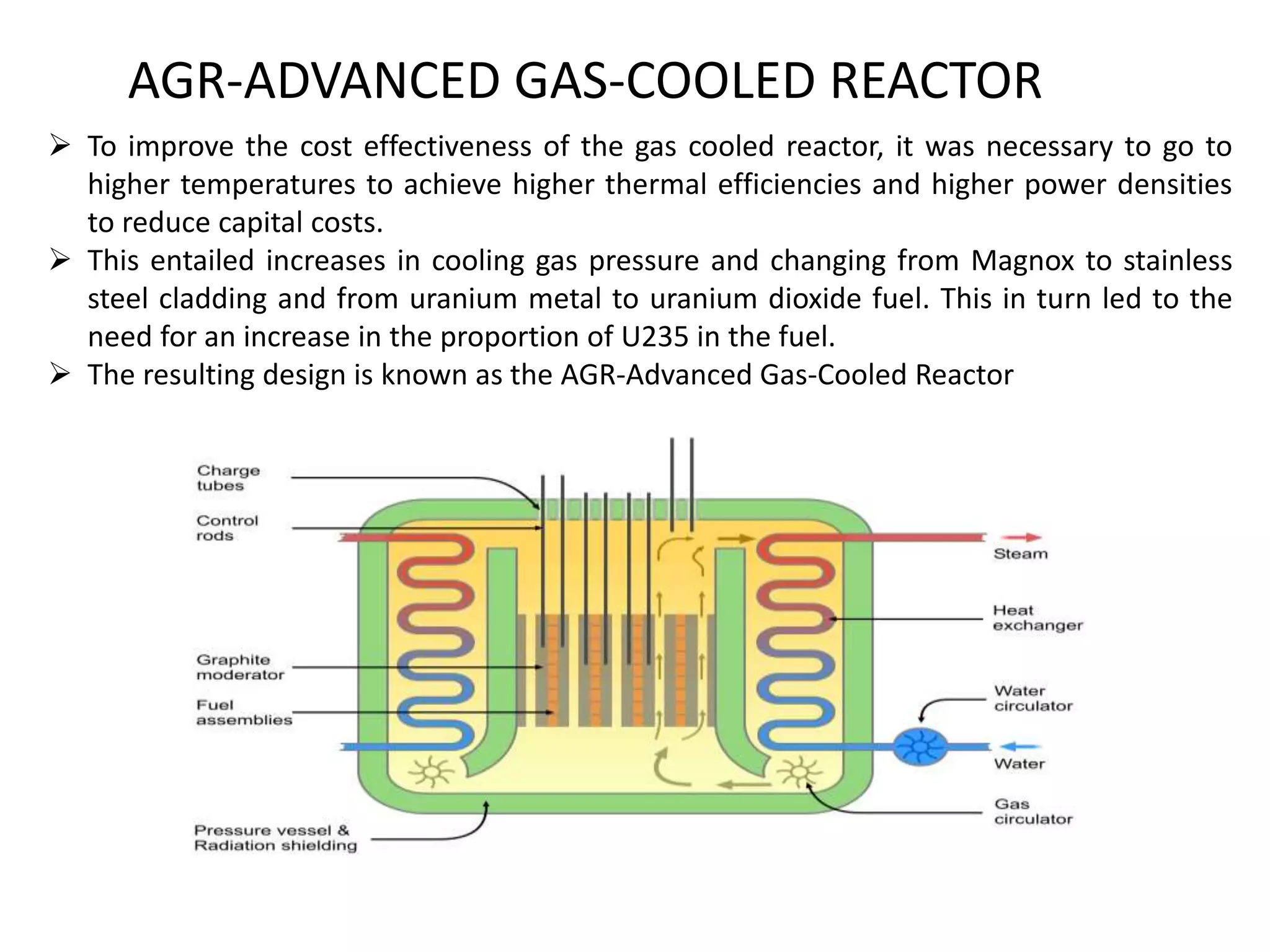

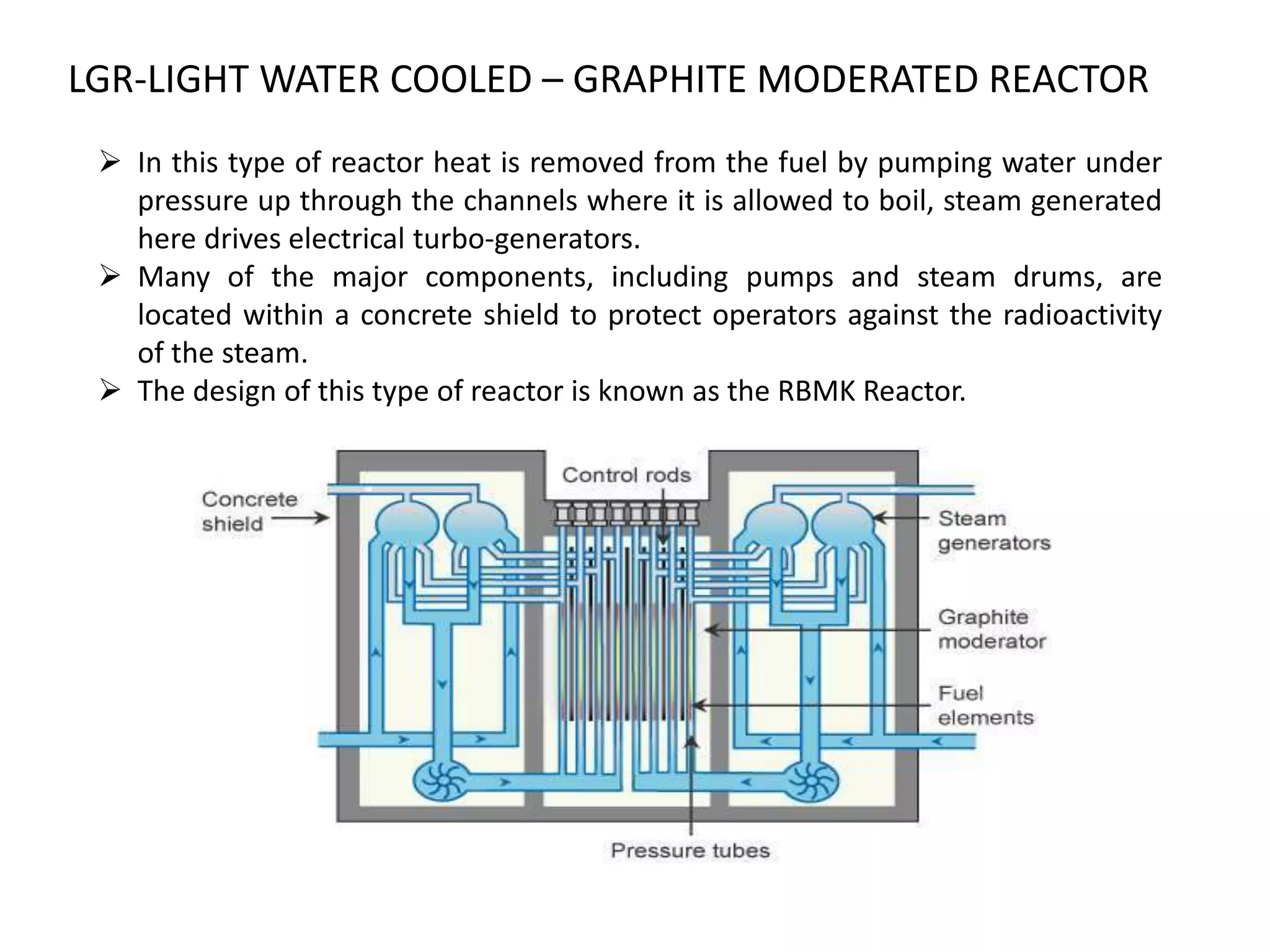

This document is a case study on various types of nuclear reactors, including their functioning and characteristics, submitted as part of the Bachelor of Technology curriculum in Electrical and Electronics Engineering. It covers the definition of nuclear reactors, their common use in generating electrical power, the mechanics of how they operate including the types of fuels and moderators used, and the classification of reactors based on different criteria. Additionally, the document details specific reactor types such as Boiling Water Reactors (BWR), Pressurized Water Reactors (PWR), and more, highlighting their advantages and disadvantages.