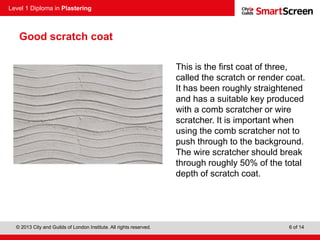

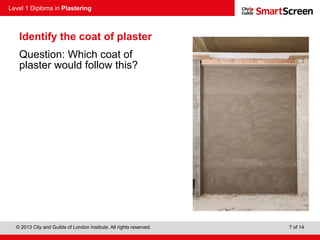

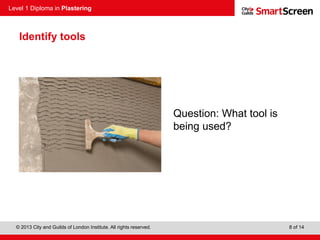

This document discusses applying scratch coats for plastering. It explains that the sand/lime material used for scratch coats needs to be well-mixed so there are no large lumps, and it should be wet enough to spread easily but not too wet or it will sag. The proper tools for applying scratch coats are listed. A good scratch coat is shown that has been roughly straightened and contains a suitable mechanical key produced using a comb or wire scratcher.